Multi-coil induction plasma torch for solid state power supply

A plasma and torch technology, applied in the direction of plasma, plasma welding equipment, electrical components, etc., can solve the problems of affecting the uniformity of the temperature field, reducing efficiency, and not being suitable for RF signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

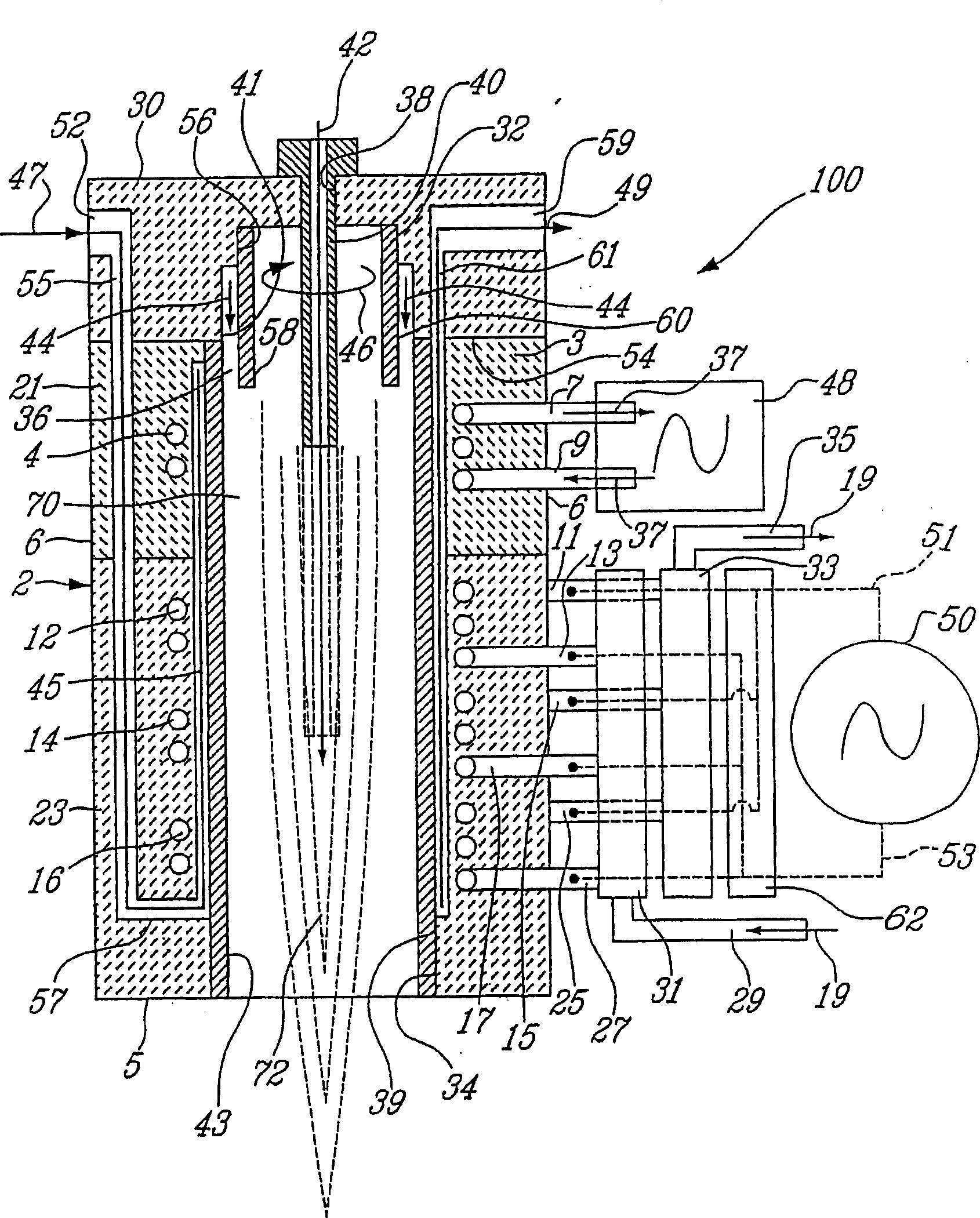

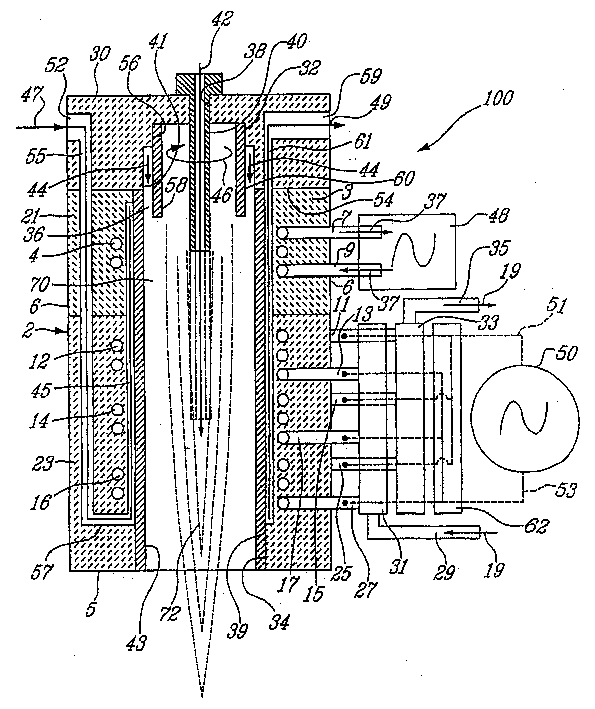

[0029] figure 1 is a multi-coil induction plasma torch generally indicated at 100 . Particularly figure 1 The illustrated exemplary embodiment forms a high impedance matched multi-coil induction plasma torch capable of generating an inductively coupled gas plasma.

[0030] figure 1 The multi-coil induction plasma torch 100 described in includes a tubular (eg cylindrical) torch body 2 consisting of proximal and distal tubular members 21 and 23 made of cast ceramic or composite polymer and Assembled end to end. Other suitable materials may also be used to manufacture the tubular members 21 and 23 of the flare body. The tubular flare body 2 has a proximal end 3 and a distal end 5 and defines an axial chamber 70 in which a plasma 72 is ignited and maintained.

[0031] still reference figure 1 In the exemplary embodiment shown, the tubular flare body 2 has an inner cylindrical surface lined with a relatively thin cylindrical plasma confinement tube 39 coaxial with the flare b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com