Preparation method for ceramic agg egate of same kind and different structure

A kind of ceramization and similar technology, applied in the field of artificial biomaterials, can solve the problems that ceramized bone products have not yet been seen, and cannot fully meet the needs of clinical and tissue engineering bone research and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

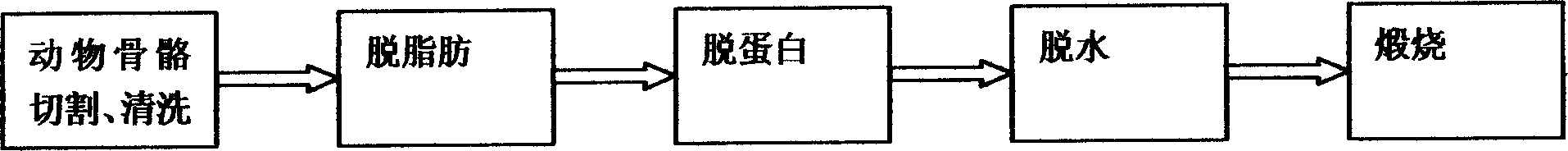

[0014] Example 1: Preparation of composite ceramic bone. Take fresh beef ribs, remove the muscles and fascia, cut the ribs longitudinally, and cross-cut them into bone pieces of different sizes; clean them, put them in 0.5mol / L sodium hydroxide solution for 14 hours, rinse them, and then put them in In 30% hydrogen peroxide for 12 hours, repeated treatment twice; then rinse with distilled water, then soak in 3:1 chloroform-alcohol mixture and acetone for 1 hour each for dehydration; then soak in ethanol for 4 hours After drying, put it in a muffle furnace for calcination at 900°C for 1 hour. After cooling, take out the composite ceramic bone and store it in a sterile container.

example 2

[0015] Example 2: Preparation of cancellous bone ceramic bone. The epiphysis of the femur was removed and cut into cancellous bone pieces of different sizes; cleaned, placed in 0.5mol / L sodium hydroxide solution for 12 hours, rinsed, and then placed in 30% hydrogen peroxide for 16 hours, Repeat the treatment twice; then rinse with distilled water, bake in an oven at 42°C for 48 hours; place in a muffle furnace for calcination at 700°C for 4 hours, take out the cancellous bone ceramic bone and put it in a sterile container after cooling save.

example 3

[0016] Example 3: Preparation of cortical bone ceramic bone. Cut the femoral shaft longitudinally, cut it into pieces, and clean it; put it in 0.5mol / L sodium hydroxide solution for 16 hours, rinse it, then put it in 30% hydrogen peroxide for 12 hours, and repeat the treatment twice; rinse it clean After soaking in ethanol for 6 hours, dry it; then place it in a muffle furnace and calcine it at 800°C for 3 hours. After cooling, take out the cortical bone-type ceramic bone and store it in a sterile container.

[0017] Granular ceramic bone is obtained by grinding and sieving any one of the above three types.

[0018] The clinical application principle of the present invention and the principle of constructing tissue engineered bone are explained as follows: Since the ceramic bone of the present invention is a group of biomaterials with different structures, it is suitable for clinical diseases such as different bone defects and nonunions, and long bone defects can be cortical b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com