Preparation method of 3D printing porous root-shaped implant tooth

A 3D printing and dental implant technology, which is applied in the fields of dental implants, dentistry, and dental prosthetics, etc., can solve the problems of inability to accurately control the porous morphology and structure, and it is difficult to ensure the micropore structure parameters of porous materials, so as to shorten the time for dental implants , to meet the accuracy and ensure the effect of stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

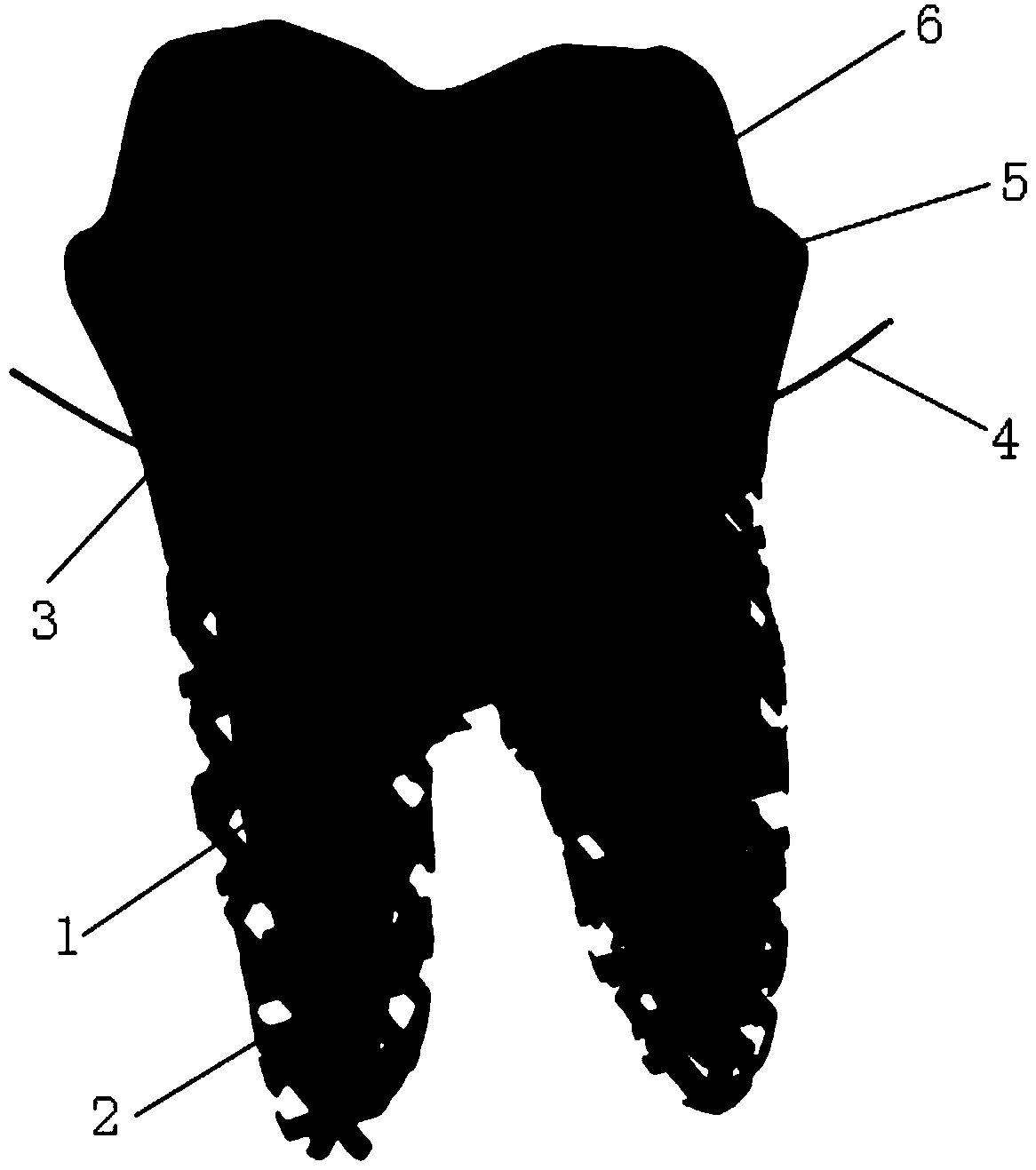

[0024] The present invention is a method for preparing 3D printing porous root-shaped dental implants. The dental implant prepared by the method is such as figure 1 As shown, the method includes the following steps:

[0025] Step 1) Use CBCT to capture the medical image data of the maxillofacial area of the patient, and import the maxillofacial medical image data into 3D image generation and editing processing software. The 3D image generation and editing processing software is Mimics software, which is adjusted according to the threshold of tissue density Edit the imported maxillofacial medical image data, delete the image of non-root 1, only keep the medical image data of the affected tooth, convert and export the STL format file of the affected tooth.

[0026] In step 1), edit the imported maxillofacial medical image data according to the threshold of tissue density. To delete the image of non-root 1 is specifically to adjust the threshold of tissue density to a high tissue de...

Embodiment 1

[0037] This embodiment provides a method for preparing 3D printed porous root implants, including the following steps:

[0038] Step 1) Use CBCT to take the medical image data of the maxillofacial area of the patient, import the maxillofacial medical image data into Mimics software, adjust the threshold of tissue density to 1250Hu, and compare the imported maxillofacial medicine according to the threshold of tissue density The image data is edited, the image of non-root 1 is deleted, only the medical image data of the tooth is retained, and the STL format file of the tooth is converted and exported.

[0039] Step 2) Import the STL format file of the affected tooth into Geomagic studio software to obtain the model of the affected tooth. Adjust the mesh of the affected tooth model to delete the visible sharp corners, undercuts and undulations, perform smoothing, and use the quadrilateral dot layout principle for precision Surface fitting, get the STL fitting model of the affected t...

Embodiment 2

[0044] This embodiment provides a method for preparing 3D printed porous root implants, including the following steps:

[0045] Step 1) Use CBCT to capture the medical image data of the maxillofacial area of the patient, import the maxillofacial medical image data into Mimics software, adjust the threshold of tissue density to 3810Hu, and compare the imported maxillofacial medicine according to the threshold of tissue density The image data is edited, and the imported maxillofacial medical image data is edited and deleted according to the threshold of tissue density. Only the medical image data of the tooth is retained, and the STL format file of the tooth is converted and exported.

[0046] Step 2) Import the STL format file of the affected tooth into Geomagic studio software to obtain the model of the affected tooth. Adjust the mesh of the affected tooth model to delete the visible sharp corners, undercuts and undulations, perform smoothing, and use the quadrilateral dot layout ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com