Method and equipment system for treating oil-containing iron scale for steel rolling

A treatment method, iron scale technology, applied in dehydration/drying/concentrated sludge treatment, iron oxide, solid waste removal, etc., can solve secondary pollution, iron scale waste oil can not be recycled and other problems, to achieve Reduce the loss of waste oil, avoid dust pollution and water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

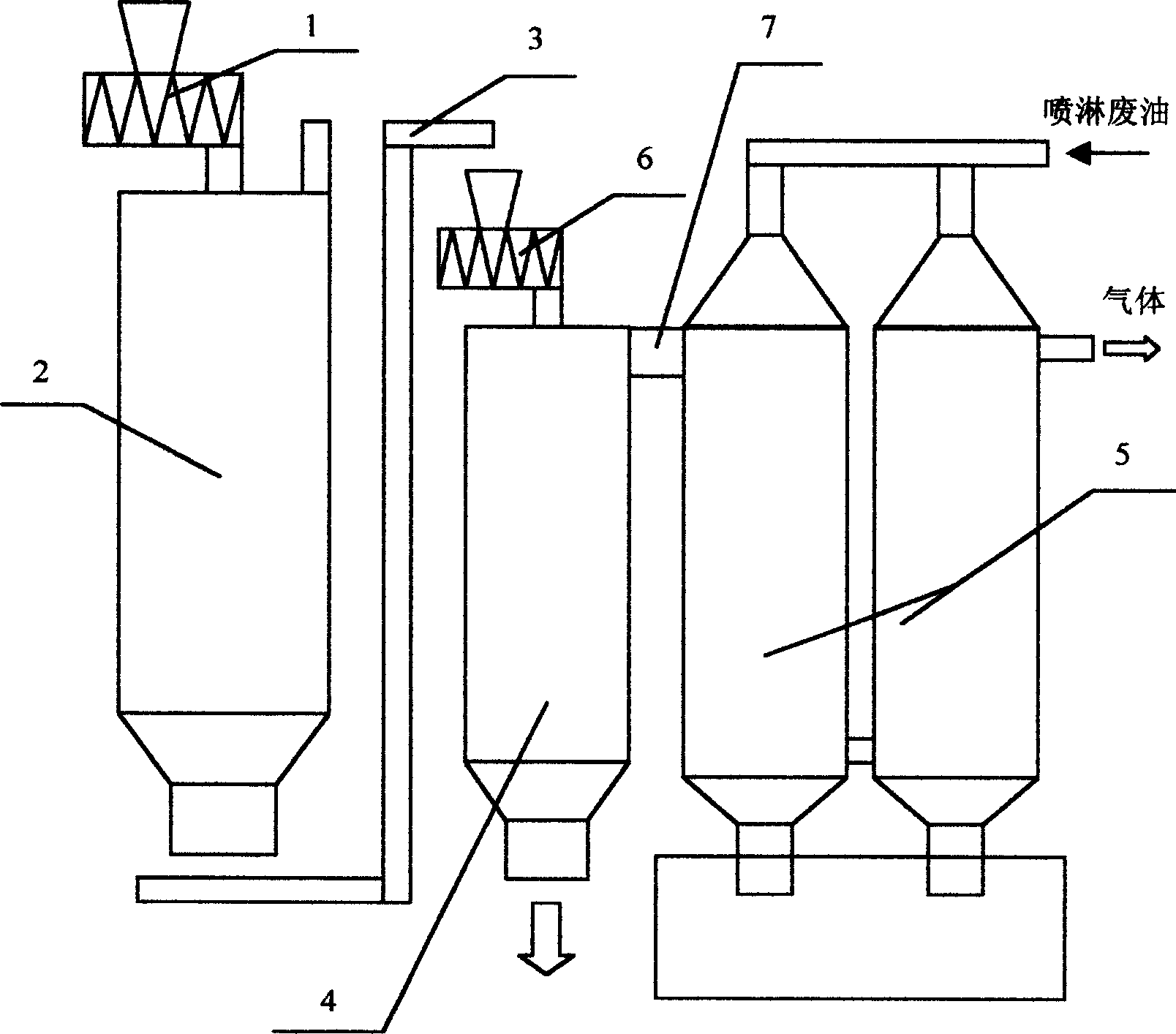

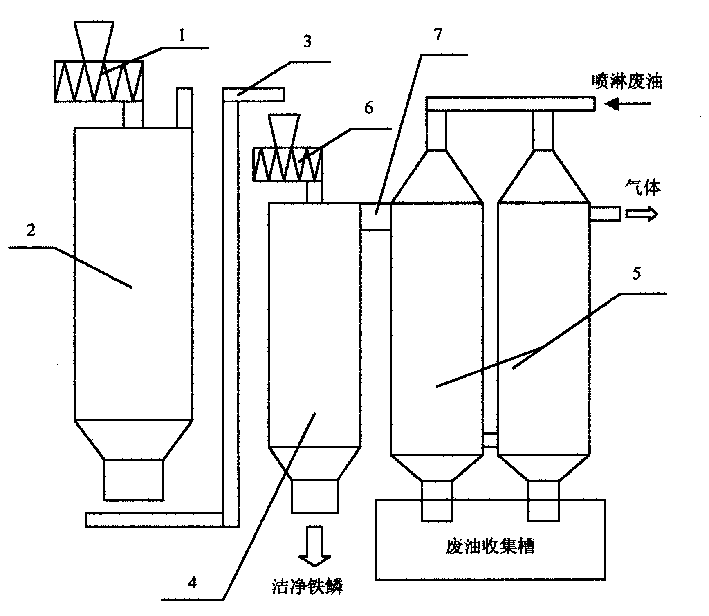

[0009] The present invention relates to a method for treating oily iron scale in rolled steel, the implementation steps of which include: (1) first drying and removing the moisture in the iron scale; (2) performing low-temperature distillation and deoiling treatment on the oily iron scale after drying and dehydration; 3) reclaiming the removed waste oil; (4) using the deoiled clean iron scales as raw materials for further deep processing. The drying and dehydration temperature range of the iron scale is controlled within the temperature range (100° C.-200° C.) below the starting boiling temperature of waste oil and above the boiling point of water. The temperature of the iron scale distillation and deoiling is controlled above the boiling temperature and below the carbonization and coking temperature, and the temperature range is between 350°C and 400°C. Waste oil recovery adopts the method of combining waste oil direct spray absorption and water indirect cooling, using recycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com