Method for preparing cyclopentanone from cyclopentanol by catalytic rectification process

A technology for preparing cyclopentanone from cyclopentanol and preparing cyclopentanone from cyclopentanol is applied in the field of preparing cyclopentanone by dehydrogenation of cyclopentanol, and can solve problems such as unusable catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

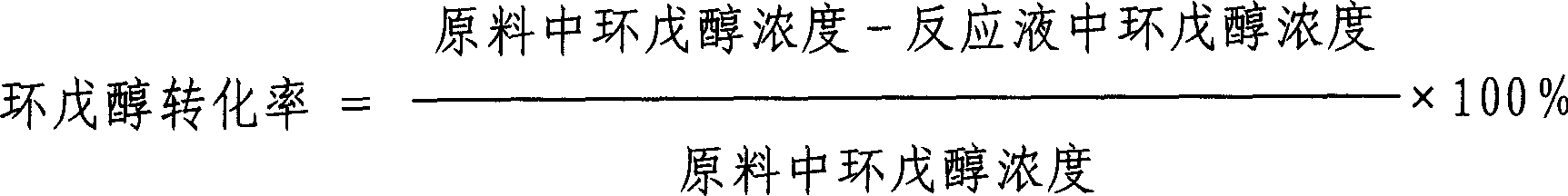

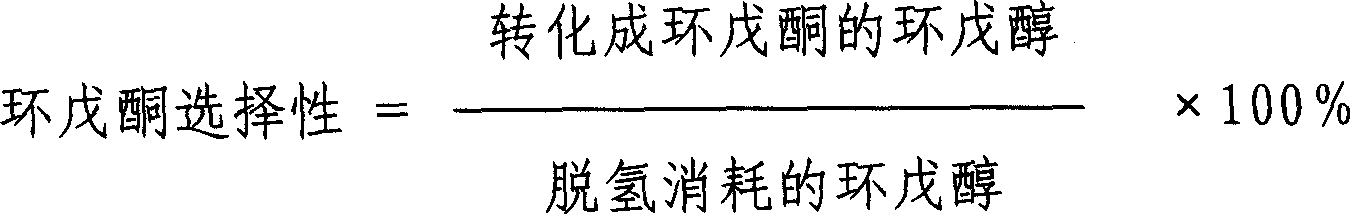

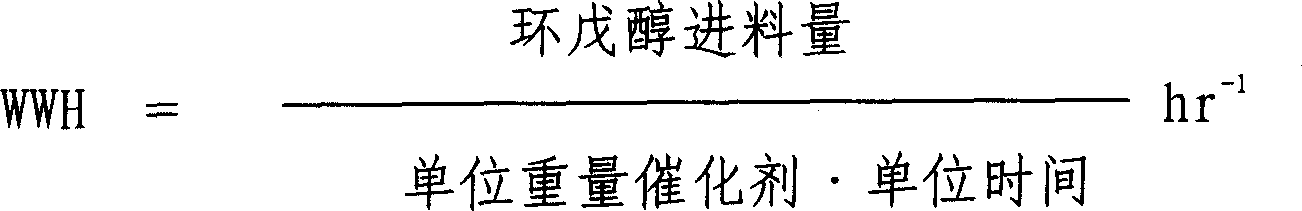

Method used

Image

Examples

Embodiment 1~10

[0024] The reaction is carried out in a reactive distillation unit, which consists of a dehydrogenation reactor and a rectification column. The reactor is a glass fluidized bed reactor with a diameter of φ25mm×510mm. A baffle full of small holes is placed at the bottom of the reactor. The diameter of the small holes is about 0.01mm, and the raw material inlet is located under the baffle. The top of the reactor is connected with a rectification column, the number of theoretical plates of the rectification column is 30, and a condensing reflux device with a vent and a discharge port is arranged on the top of the rectification column.

[0025] First add 600 grams of cyclopentanol into the reactor, and then add 100 grams of modified amorphous Raney nickel catalyst with a particle size of 0.03 to 0.05 mm into the reactor, and place the catalyst on a baffle. The reactor is heated to 130-140° C., and then the cyclopentanol is pumped continuously into the reactor while maintaining the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com