Biological catalysis method for preparing methanol from carbon dioxide

A technology of carbon dioxide and biocatalysis, applied in the direction of fermentation, etc., can solve the problems of low conversion rate and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

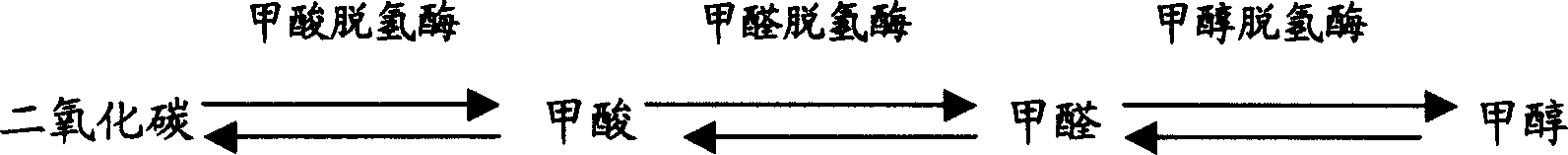

Method used

Image

Examples

Embodiment 1

[0018] Methane-oxidizing bacteria Methylosimus trichosporium IMV 3011 was fermented and harvested by centrifugation after fermentation. The harvested cells were added to a 100-ml Erlenmeyer flask together with 20 ml of the reaction solution containing the following components. The cells of the methane-oxidizing bacteria Methylosimus trichosporium IMV 3011 The concentration in the reaction solution is 2-10 mg / ml:

[0019] Disodium hydrogen phosphate at a concentration of 50-100 mmol / l,

[0020] Sodium dihydrogen phosphate at a concentration of 50-100 mmol / l,

[0021] Magnesium chloride at a concentration of 5 mmol / L,

[0022] pH=6.5-6.9.

[0023] One of the bottles was sealed and 80 milliliters of air was pumped out, and 80 milliliters of carbon dioxide was added as a control; the other bottle was sealed and 80 milliliters of air was pumped out, and 80 milliliters of nitrogen was added; 32 degrees Celsius, 150 rpm shaking table reaction; detection and quantitative analysis of...

Embodiment 2

[0031] Others are the same as in Example 1, the content of carbon dioxide in the reaction gas is 100%. 32 degrees Celsius, 150 rpm shaker reaction, each batch reaction is 5-7 hours, after the reaction is completed, the product is centrifuged, and the cells are recovered to proceed to the next batch of reaction. Take 0.5 ml of cell liquid from the sealed reaction bottle every hour, centrifuge to obtain supernatant, detect the product methanol with gas chromatography, and then compare its production trend. The results are shown in Table 2:

[0032] Batch / 5-7 hours Methanol output

[0033] 1 3.6 (micromole)

[0034] 2 4.4 (micromole)

[0035] 3 4.2 (micromole)

[0036] 4 3.3 (micromole)

[0037] 5 3.1 (micromole)

[0038] By comparison, it was found that the catalytic activity of methane-oxidizing bacterial cells did not decrease significantly after repeated experiments.

Embodiment 3

[0040] Others are the same as in Example 1, the concentration of carbon dioxide in the reaction gas is changed to 40%. Change the cell concentration and react on a shaker at 32 degrees Celsius and 150 rpm for 5-7 hours. After the reaction was completed, the product was separated by centrifugation, and the product methanol was detected by gas chromatography. The results are shown in Table 3:

[0041] Cell concentration Methanol production

[0042] 2 mg / ml 2.8 (micromole)

[0043] 4 mg / ml 3.9 (micromole)

[0044] 6 mg / ml 4.5 (micromole)

[0045] 8 mg / ml 4.1 (micromole)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com