Cyclodextrin linkage silica gel fixed phase, preparing method and use thereof

A technology of bonding silica gel and cyclodextrin, which is applied to chemical instruments and methods, other chemical processes, instruments, etc., can solve the problems of separation selectivity, cumbersome operation, easy hydrolysis, etc., to improve the symmetry of chromatographic peaks, reduce Separation and purification, increase the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

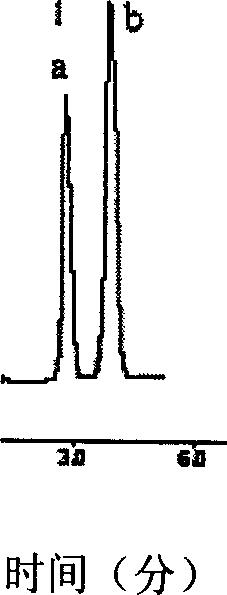

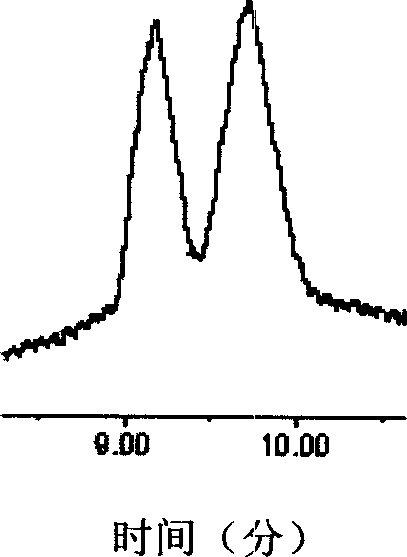

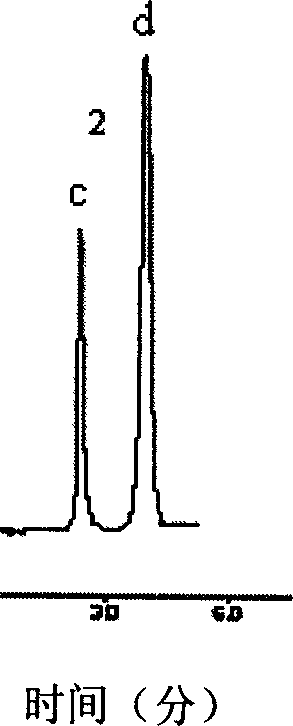

Image

Examples

preparation example Construction

[0015] 1. Preparation of cyclodextrin-bonded silica gel stationary phase

[0016] 1.1 Preparation of halopropyl-bonded silica gel

[0017] According to the ratio of silica gel: coupling agent: anhydrous toluene: 1g: 5mmoL: 50ml, add 150ml freshly distilled anhydrous toluene (anhydrous toluene is prepared by refluxing metal sodium to remove water) into a 250ml three-necked flask, and quickly add activated particle silica gel (particle size 5 μm, Kromasil, Sweden), and then add halopropyltriethoxysilane coupling agent. Protected by dry nitrogen (the nitrogen has been pre-dried by concentrated sulfuric acid and calcium chloride), under magnetic stirring, add 3 drops (about 0.1ml) of freshly distilled triethylamine dropwise, and the oil bath is heated rapidly to 110-120°C, and react under reflux After 24 hours (a drying tube with anhydrous calcium chloride is installed on the upper end of the condensation tube), suction filter with a G-4 sand core funnel while it is hot, and wash...

specific Embodiment approach

[0018] 1. Preparation of cyclodextrin-bonded silica gel stationary phase

[0019] 1.1 Preparation of activated silica gel

[0020] Suspend silica gel (particle size 5 μm, Kromasil, Sweden) in 6 mol / L hydrochloric acid, the mass ratio of silica gel to hydrochloric acid volume is 1 g: 15-20 ml. Reflux for 24 hours under stirring, filter with a G-4 sand core funnel while it is hot, wash the solid repeatedly with water twice to neutrality, and wash it with acetone three times, dry it under an infrared lamp until the silica gel is dispersed, and then dry it in an oven at 160°C After more than 10 hours, take it out and place it in a desiccator to cool to room temperature, quickly transfer it to a vacuum drying gun, heat it in a water bath, and dry it in vacuum for more than 16 hours to obtain activated silica gel.

[0021] 1.2 Preparation of halopropyl-bonded silica gel

[0022] According to the ratio of silica gel: coupling agent: anhydrous toluene: 1g: 5mmoL: 50ml, add 150ml fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com