Promoter for solid electrolyte film of lithium cell

A solid electrolyte membrane and accelerator technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve good uniformity, improve cycle life, and prevent electrochemical agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Deposit nano-silver particles with a particle size of 0.3nm on the electrode surface using tin-antimony alloy as the electrode material: use the method of physical vapor deposition, add evaporation source Ag in a vacuumed physical vapor deposition furnace, and deposit on the tin-antimony alloy electrode On the substrate of the sheet, the deposition time was 2 minutes.

[0030] Dry the electrode sheet with nano-metal silver deposited on the surface at 150° C. for 12 hours. After drying, the composite material is cut to an area of 1cm 2 The circular sheet was used as a composite electrode to investigate its electrochemical performance as a negative electrode active material for a secondary lithium battery, and an experimental button battery was used for research. The experimental battery structure is as Figure 6 As shown, the electrolyte is 1 mol / liter lithium hexafluorophosphate (LiPF 6 ) dissolved in acrylic carbonate solution, dry the stainless steel sealing nut ...

Embodiment 2~55

[0032] According to the method in Example 1, accelerators with different compositions and particle sizes were deposited on the surface of the electrode, and the properties of the electrode were tested. The measured data are listed in Table 1.

[0033]

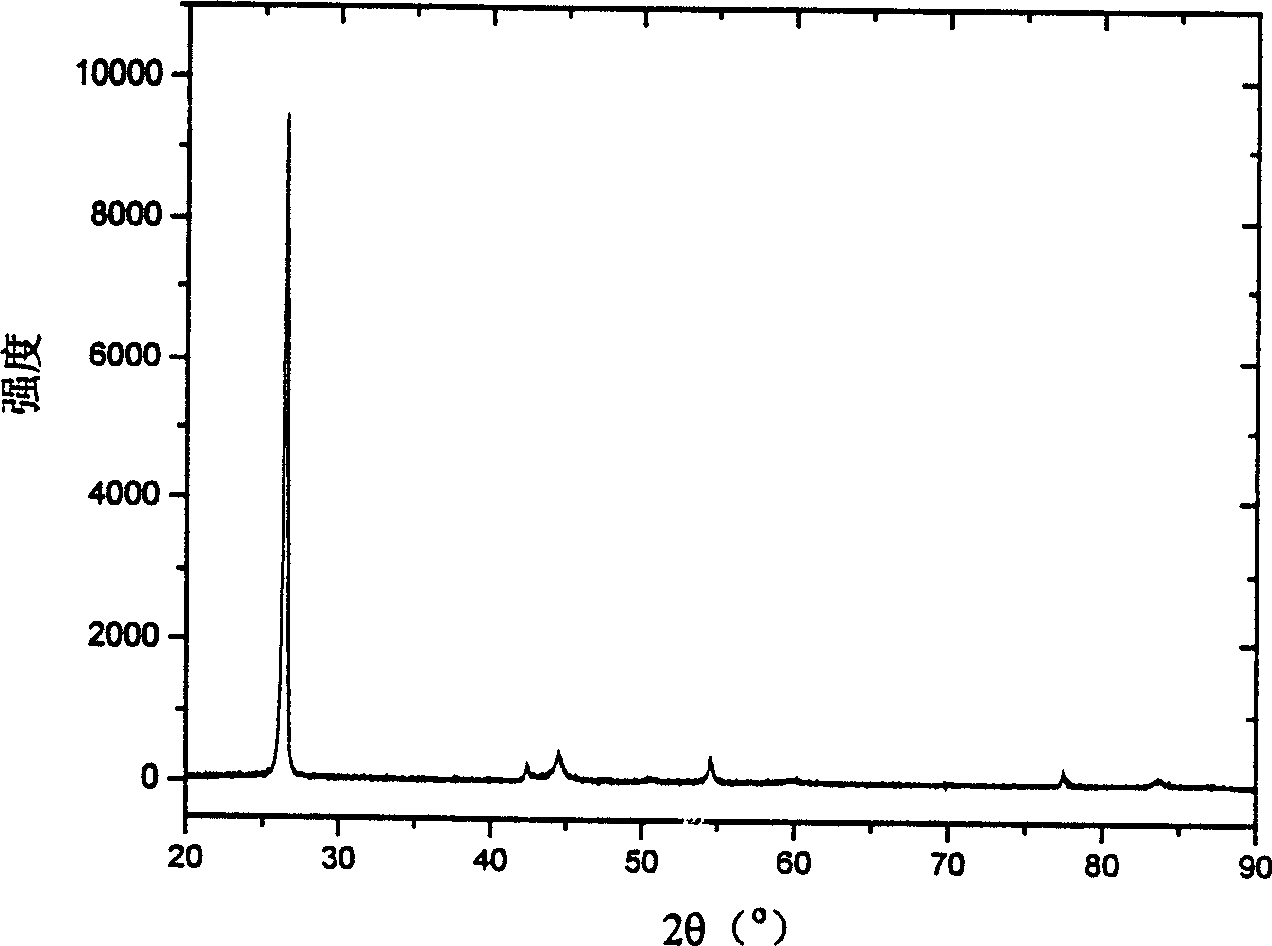

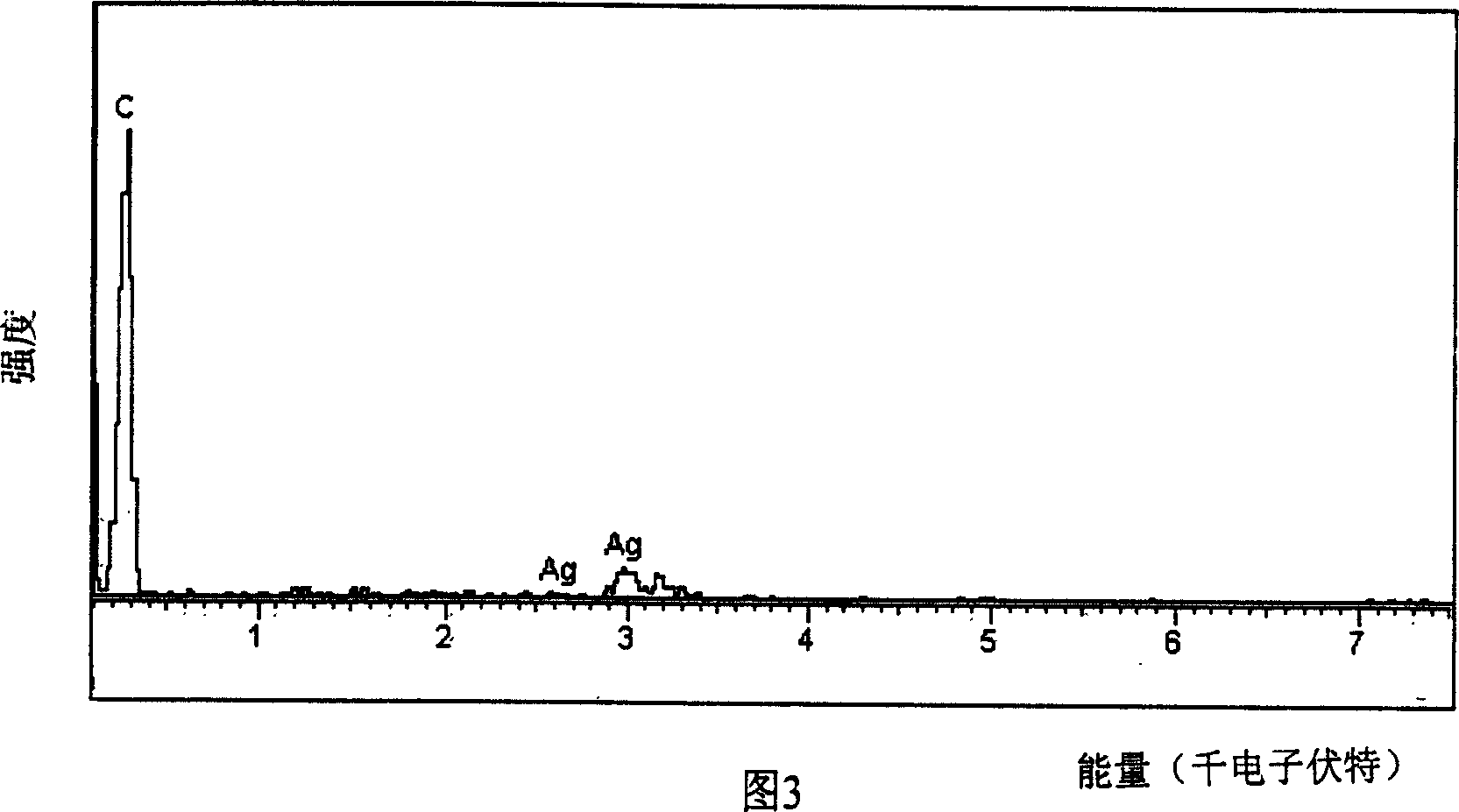

[0034] The obtained composite material of material in embodiment 5 is done X-ray diffraction as figure 1 As shown, it can be seen that the obtained material has no other substances except MCMB and nanosilver. figure 2 It is a scanning electron microscope photo of the composite material obtained. It can be seen that the nano-silver particles have a size of 8 nanometers and are attached to carbon spheres with an average size of 5 microns. The X-ray energy dispersive analysis results of its surface selection are shown in Figure 3, indicating that the material is a carbon-silver composite material. The scanning electron microscope image of the electrode surface after 20 weeks of material circulation is shown in Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com