Aluminum-based multinary alloys and their use as heat- and corrosion-resistant coatings

一种多元合金、合金的技术,应用在耐热耐腐蚀涂层且必要时还可以与其他层结合使用的合金,燃气涡轮机或喷气发动机的元件涂层领域,能够解决金属高蒸汽压、贵金属损失、金属昂贵等问题,达到高熔点的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

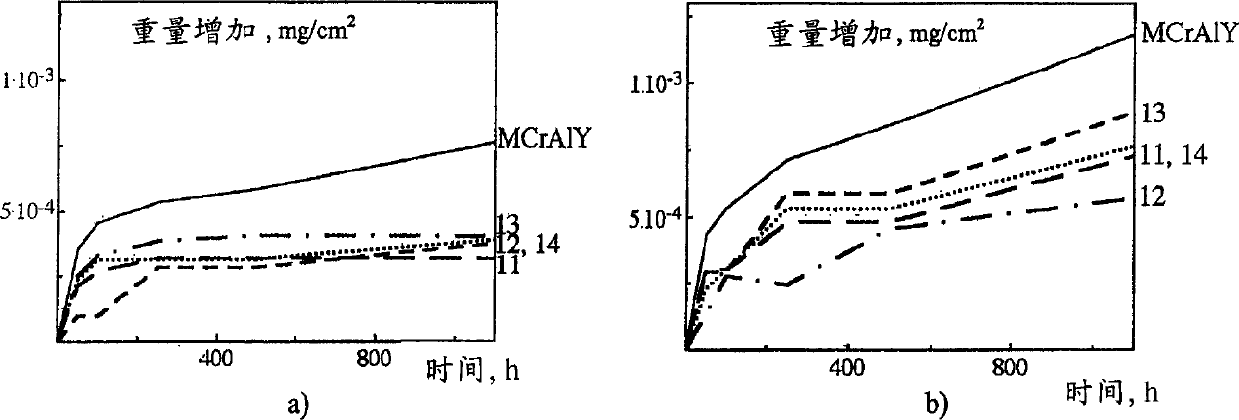

[0040] Thermal decomposition and oxidation of gas turbine or jet engine components are subject to thermal decomposition and oxidation under the combined action of high temperatures and oxidative reactions or a corrosive environment, which limits the possible operating temperatures (which leads to a reduction in the efficiency of the turbine) and shortens the life of the components lifespan (and consequently lead to increased maintenance costs). Generally, modern heat-resistant and anti-oxidative protection systems are regarded as a 3-layer structure: nickel (Ni)-based superalloy substrate SX, bonding layer (adhesive layer, BC, MCrAlY or nickel-aluminide) and thermal insulation The outermost layer of oxide (thermal barrier coating, TBC, generally YSZ).

[0041] Unfortunately, this combined structure suffers from YSZ layer splitting in hot and aggressive environments. This happens due to the poor coordination of the thermal expansion coefficients of the metal and ceramic parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com