Ferrimagnetic semimetal and preparation method thereof

A ferrimagnetic, semi-metallic technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of low efficiency of spin polarized electrons and low efficiency of spin electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] La with a purity higher than 99.9% 2 O 3 , Fe 2 O 3 , Re 2 O 7 , CuO and Re powder were mixed at a molar ratio of 7:21:9:42:10, and ground in an argon-filled glove box for 2 hours to obtain a mixture with a particle size of 200 mesh. The mixture was filled and sealed in gold capsules with a wall thickness of 0.1 mm. The gold capsules are placed in a six-sided top press, and under the conditions of a pressure of 8 GPa and a temperature of 1000° C., the raw materials in the gold capsules are reacted for 30 minutes to obtain a reaction product. After cooling to room temperature within 15 seconds, the pressure was slowly released, and finally the reaction product was taken out from the gold capsule to obtain LaCu 3 Fe 2 Re 2 O 12 .

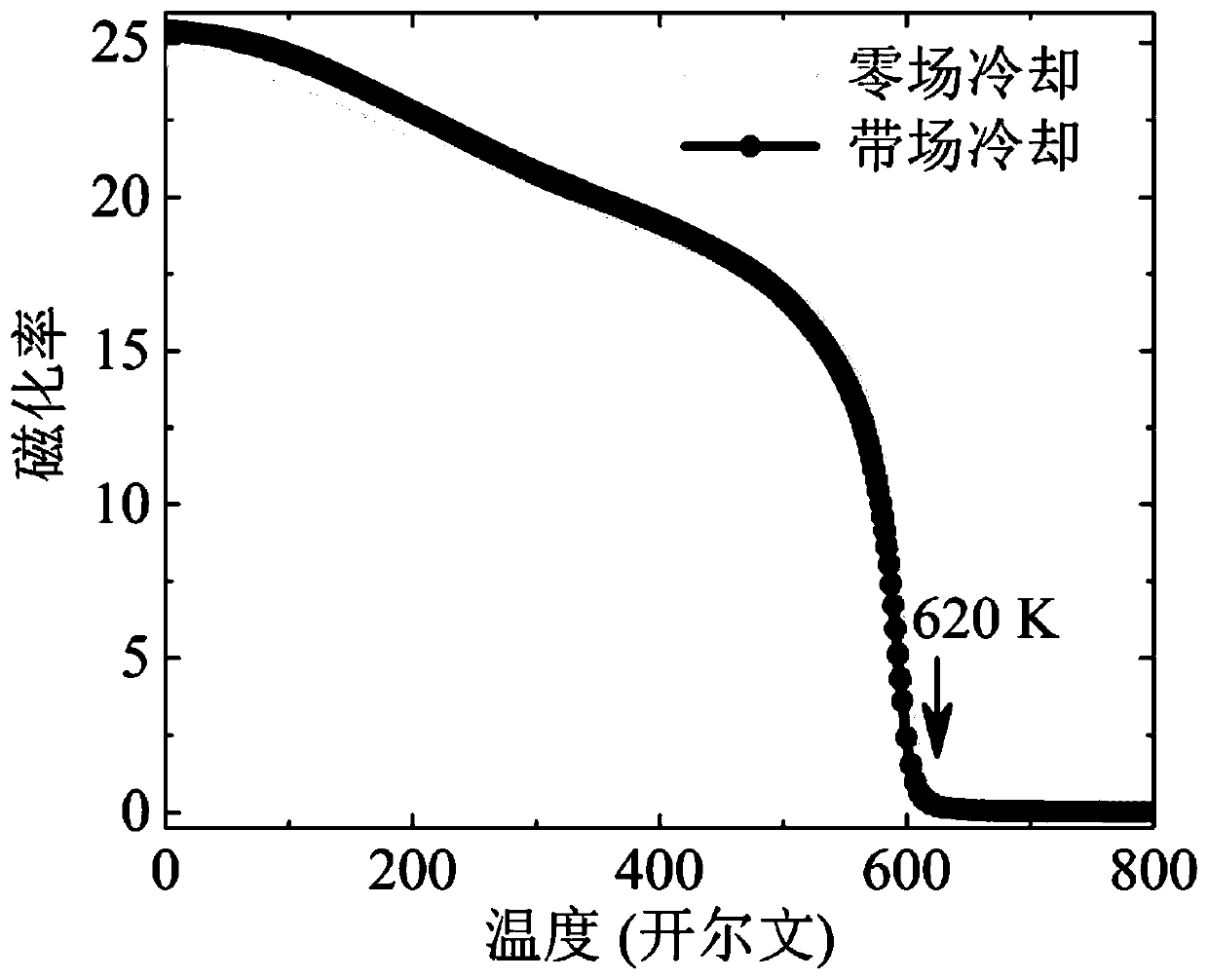

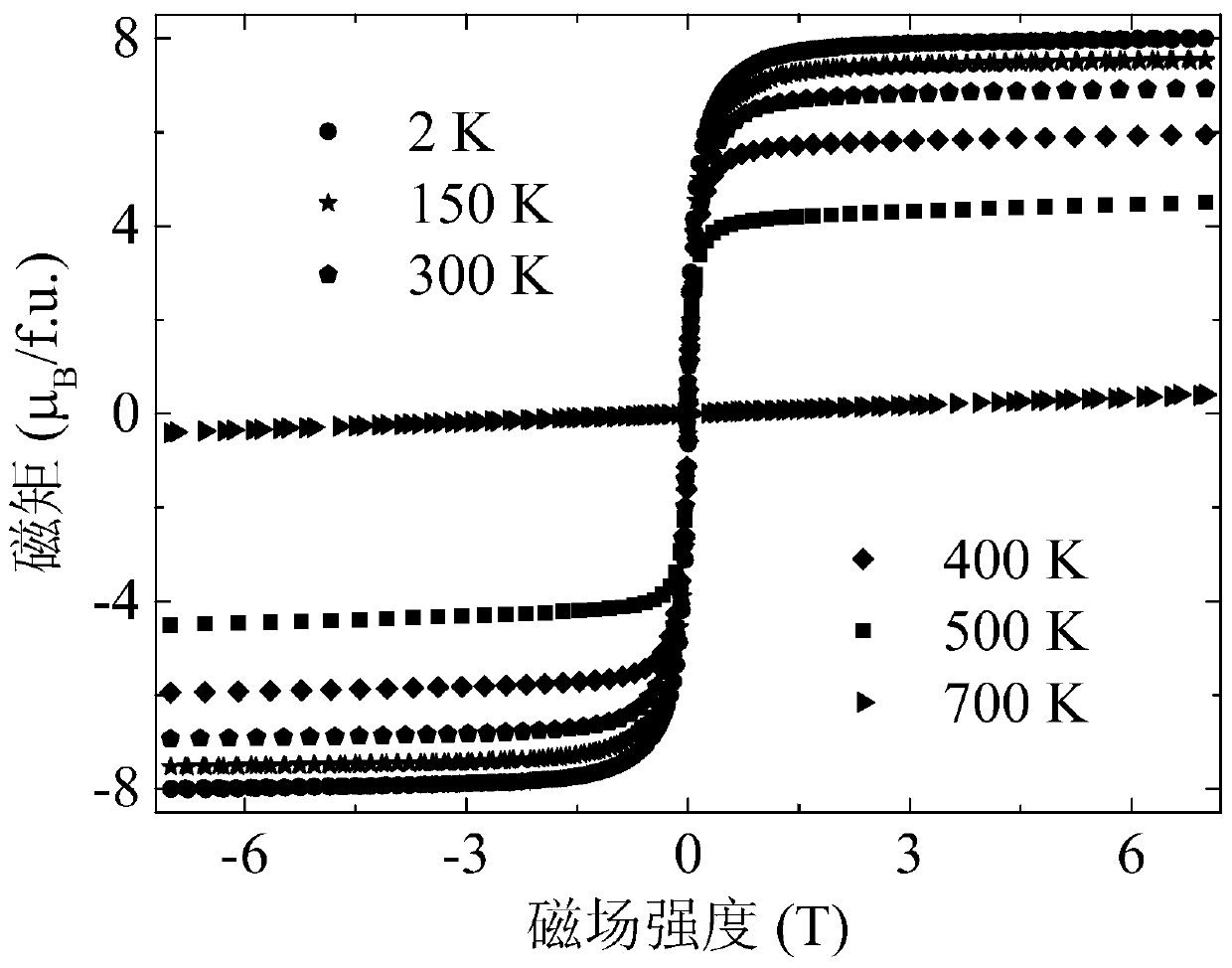

[0040] Performance measurement

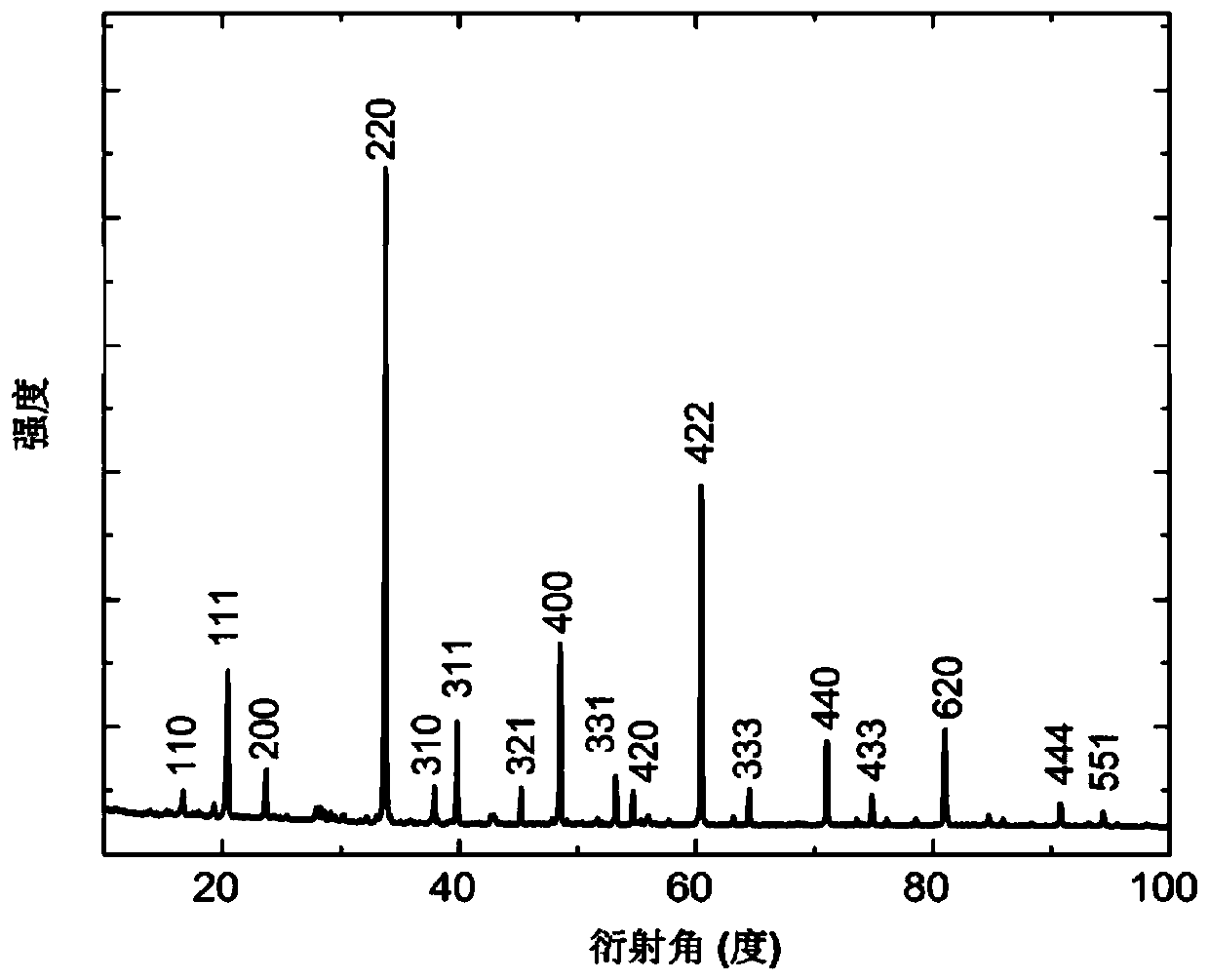

[0041] 1.XRD test

[0042] The structure of the semimetal was characterized by an X-ray diffractometer produced by Huber, Germany. Among them, the target material generated by X-ray is a copper ta...

Embodiment 2

[0057] La with a purity higher than 99.9% 2 O 3 , Fe 2 O 3 , Re 2 O 7 , CuO and Re powder were mixed in a molar ratio of 7:21:9:42:10, and ground in an argon-filled glove box for 30 minutes to obtain a mixture with a particle size of 1000 mesh. The mixture was filled and sealed in platinum capsules with a wall thickness of 1 mm. The platinum capsules are placed in a 6-8 type two-stage propelling press, and the raw materials in the gold capsules are reacted for 40 minutes under the conditions of a pressure of 10 GPa and a temperature of 1100° C. to obtain a reaction product. It took 2 hours, and after the temperature dropped to room temperature, the pressure was slowly released, and finally the reaction product was taken out from the gold capsule to obtain LaCu 3 Fe 2 Re 2 O 12 .

[0058] The ferrimagnetic semi-metal LaCu prepared in this example 3 Fe 2 Re 2 O 12 The structure and performance are the same as those in Example 1.

Embodiment 3

[0060] La with a purity higher than 99.9% 2 O 3 , Fe 2 O 3 , Re 2 O 7 , CuO and Re powder were mixed at a molar ratio of 7:21:9:42:10, and ground in an argon-filled glove box for 1 hour to obtain a mixture with a particle size of 500 mesh. The mixture was filled and sealed in gold capsules with a wall thickness of 0.5 mm. The gold capsules are placed in a six-sided top press, and under the conditions of a pressure of 9 GPa and a temperature of 1050° C., the raw materials in the gold capsules are reacted for 60 minutes to obtain a reaction product. It took 10 hours, after the temperature dropped to room temperature, the pressure was slowly released, and finally the reaction product was taken out from the gold capsule to obtain LaCu 3 Fe 2 Re 2 O 12 .

[0061] The ferrimagnetic semi-metal LaCu prepared in this example 3 Fe 2 Re 2 O 12 The structure and performance are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com