Energy saving control system of frequency conversion in use for central air condition

An energy-saving control system and central air-conditioning technology, applied in heating and ventilation control systems, heating and ventilation safety systems, space heating and ventilation, etc. It can reduce motor wear, prolong the average service life, and avoid energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

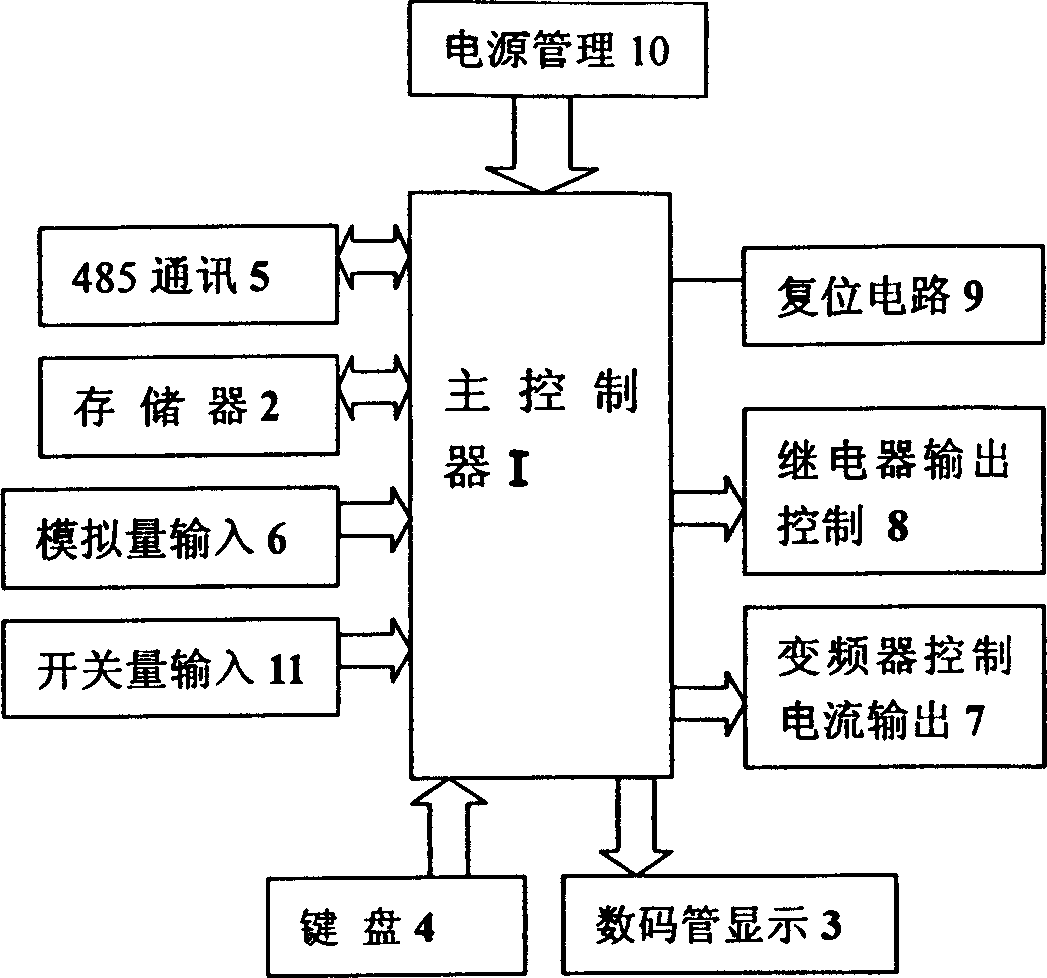

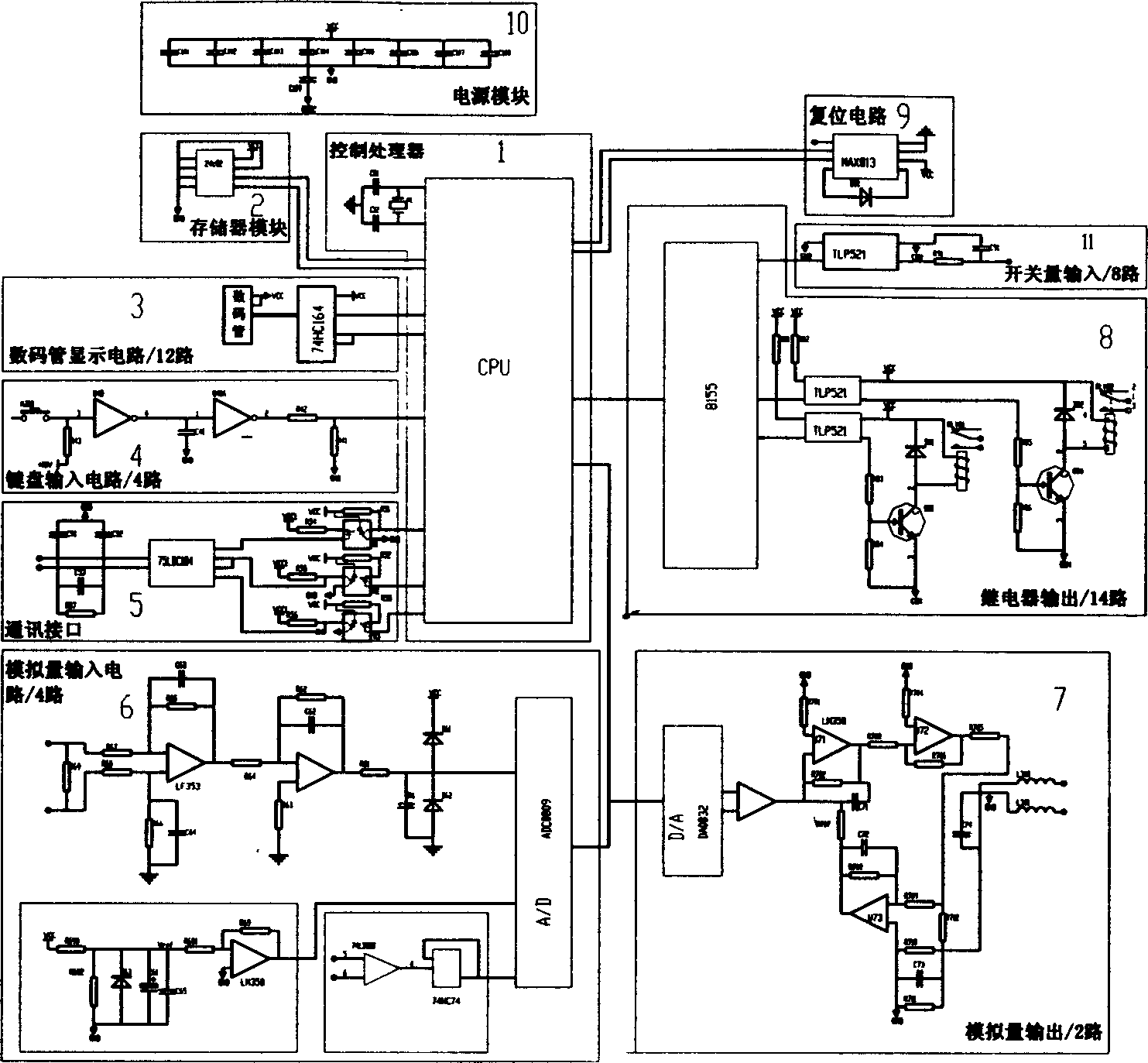

[0023] Master Controller 1: see figure 1 and image 3 , the main control chip is Winbond W78E51, the passive crystal oscillator M1 and capacitors C11 and C12 form an oscillation circuit, which provides a clock reference for the controller.

[0024] Memory circuit 2: The memory is 24c02.

[0025] Nixie tube display circuit 3: each way of nixie tube display circuit consists of a piece of 74HC164 and a nixie tube, 74HC164 provides driving current for the nixie tube;

[0026] Keyboard input circuit 4: composed of keyboard, inverter, pull-up resistor R43, filter capacitor C41, current limiting resistor R42, and pull-down resistor R41;

[0027] Communication interface 5: composed of optocouplers N1, N2, N3, pull-up resistors R51, R55, R56, current limiting resistors R52, R53, R54, communication chip SN75LBC184, capacitors C51, C52, C53 and resistor R57;

[0028] Analog input circuit 6: It is composed of A / D conversion circuit ADC0809 chip, operational amplifier LF353, LM358 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com