High purity functional alkaline mineral salt, method and apparatus for manufacturing the same

A manufacturing method and functional technology, applied in the field of high-purification functional alkaline mineral salt and its manufacture and device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

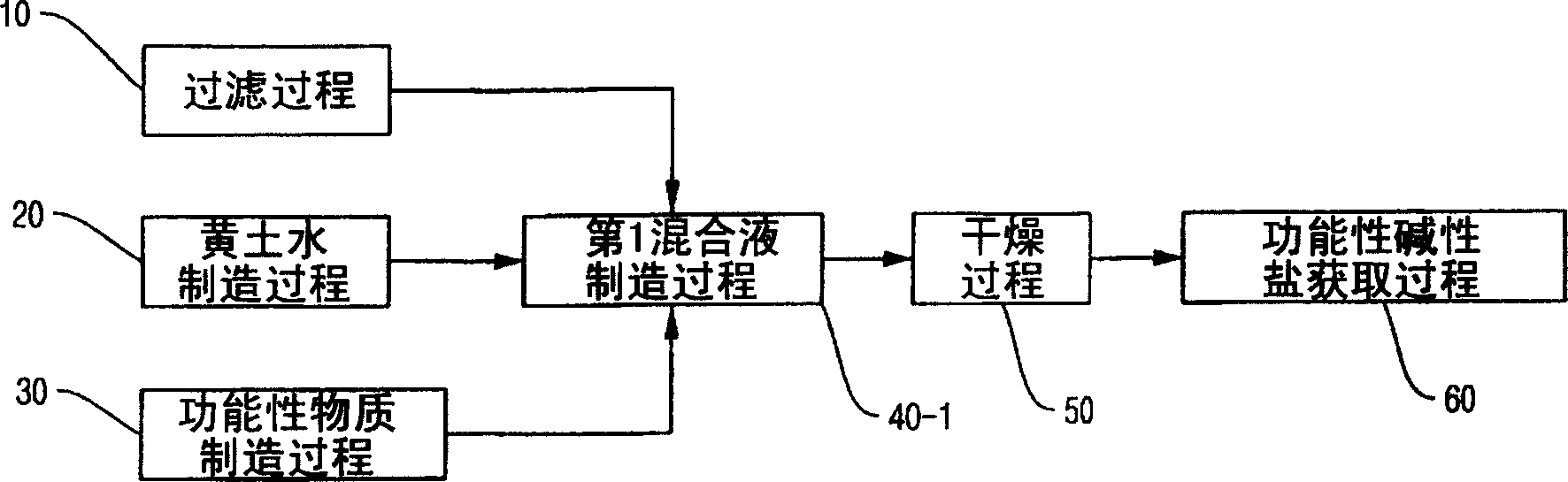

[0085] see figure 1 , is a process diagram of the method for producing functional alkaline mineral salt in the first embodiment of the present invention.

[0086] As shown in the figure, in the manufacturing method of this embodiment, the filtering process 10, the loess water manufacturing process 20, and the functional substance manufacturing process 30 are respectively performed.

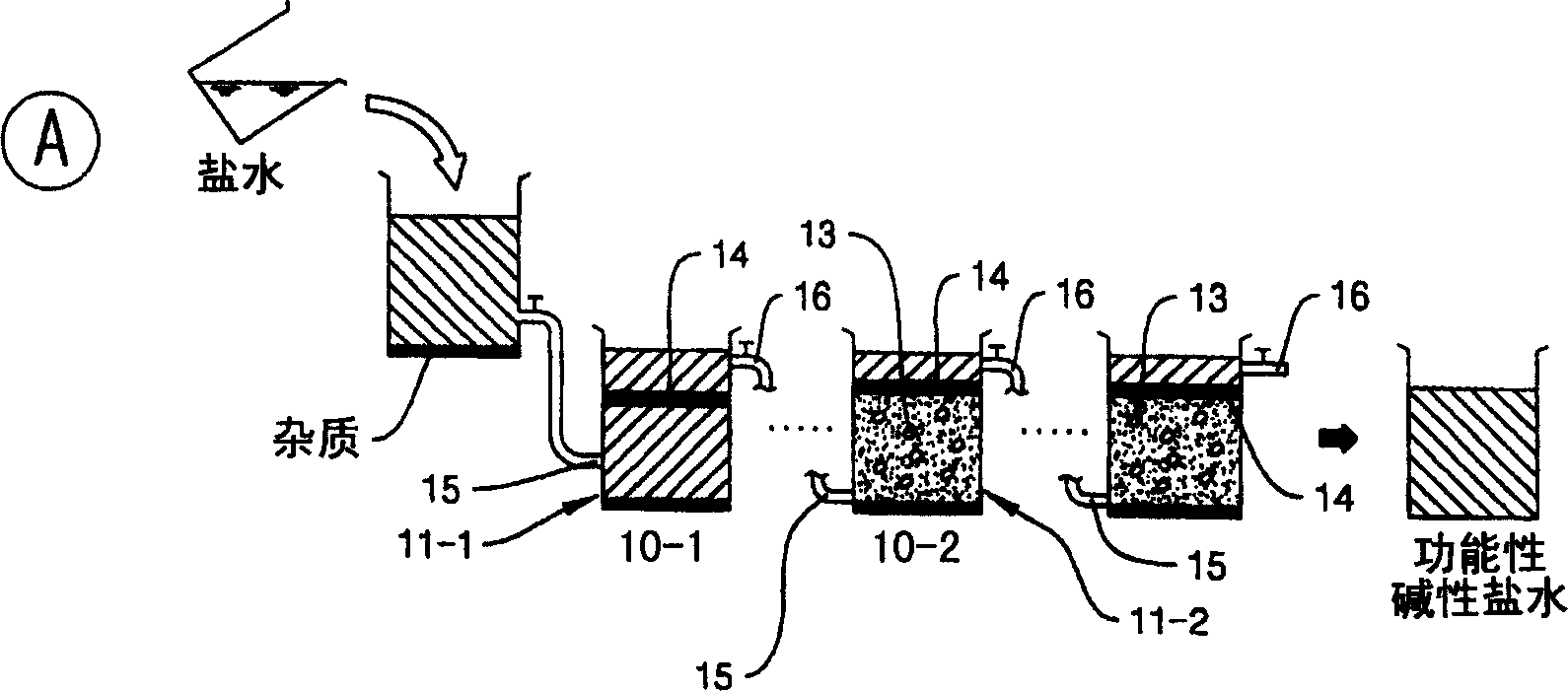

[0087] In the above-mentioned filtering process 10 and loess water manufacturing process 20, as image 3 and Figure 4 As shown, in order to remove impurities or harmful toxic substances in various aqueous solutions, the filtration process is carried out. Such a filtering process can also be implemented in the functional substance manufacturing process 30 . Especially above-mentioned filtration process 10 is to carry out in order to improve the degree of purification of salt, therefore, can as image 3 As shown, it is divided into 1 and 2 filtering processes 10-1 and 10-2 to carry out. image...

Embodiment 2

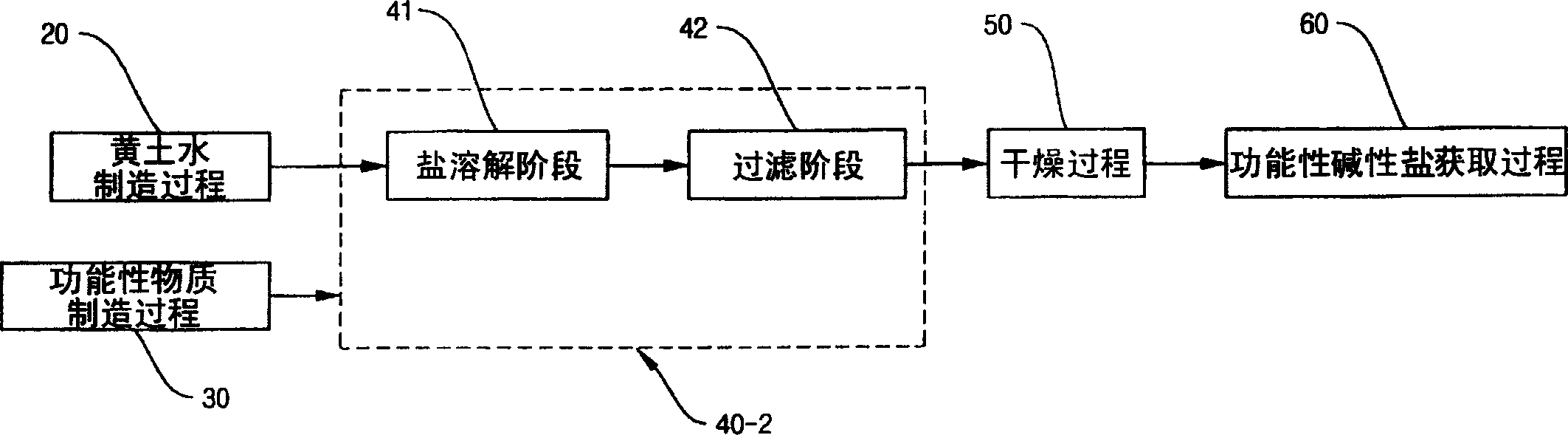

[0097] see figure 2 , is a process diagram of the manufacturing method of the second embodiment of the present invention.

[0098] As shown in the figure, in this embodiment, the loess water production process 20 and the functional substance production process 30 are separately performed.

[0099] Here, the above-mentioned processes 20, 30 are the same as in the embodiment 1, and a filtering process and a moisture reduction stage 21 can be additionally performed.

[0100] Next, the second mixed liquid production process 40-2 of mixing salt and functional substances in the loess water is performed.

[0101] The second mixed solution manufacturing process 40-2 includes: a salt dissolving stage 41 of dissolving salt in loess water (loess water mixed with functional substances); introducing the second mixed solution obtained through the salt dissolving step 41 into image 3 In the shown filter tank 11 , the sedimentation and filtration stage 42 - 1 of precipitating harmful and ...

Embodiment 3

[0104] see Figure 6 , is a process diagram of the method for producing functional alkaline mineral salt in the third embodiment of the present invention.

[0105] As shown in the figure, the manufacturing method of this embodiment is performed through one filtering process 10 - 1 , two filtering processes 10 - 2 and a drying process 50 .

[0106] Above-mentioned 1st, 2nd filtration process is identical with the filtration process among the embodiment 1. In this filtration process, filter agents 13 such as white carbon, common charcoal or loess balls are set in the filter tank 11 body to remove impurities or harmful toxic substances in the aqueous solution, and various minerals and alkalis dissolved from the filter agent The ability of the active ingredient to penetrate into the aqueous solution.

[0107] In addition, a heating process can be added to the above-mentioned filtration process to increase the solubility of minerals and alkaline components, and a process of mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com