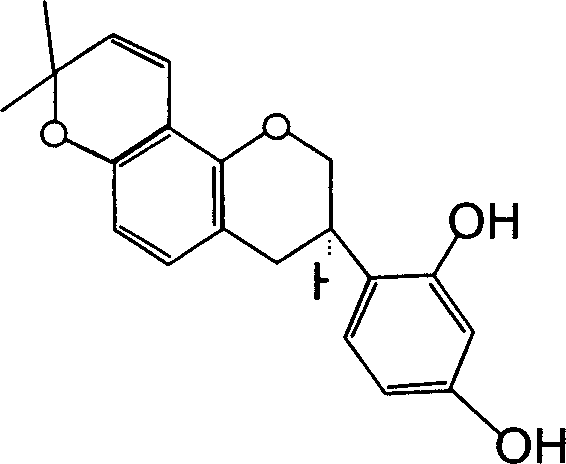

Method for producing glabridin product

A production method and technology of glabridin, which can be applied in the fields of anti-toxic agent, organic chemistry, drug combination, etc., can solve the problems of reported and unseen glabridin production technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First dry and pulverize the licorice glabra, then put the crushed licorice glabra and ethyl acetate into a reflux heating device according to the ratio of 1:10, heat and reflux together for 8 hours, filter and wash. Repeat twice, combine the filtrate and washings, concentrate, recover the solvent, and dry under reduced pressure to obtain a residue, which is a crude product.

[0017] The above crude product was ground, dissolved in a small amount of chloroform, and the solution was carefully added to a pre-treated silica gel column filled with silica gel (the silica gel was produced by Qingdao Ocean Chemical Factory). With chloroform, acetone gradient elution. The effluent was examined by silica gel thin-layer chromatography detection (color development with dilute sulfuric acid). The target liquid was collected, concentrated under reduced pressure, and dried in vacuo. Add a small amount of ethanol to dissolve the residue, filter, and then concentrate the filtrate unde...

Embodiment 2

[0019] Dry and pulverize Glycyrrhizae glabra first, then put the crushed licorice glabra and dichloromethane into a percolator at a ratio of 1:5, percolate, and recover when a colorless liquid flows out (about 10 hours). solvent, and the residue was dried in vacuo to obtain a crude product.

[0020] The above crude product was dissolved in a small amount of chloroform, and the solution was carefully added to a pre-treated silica gel column filled with silica gel (the silica gel was produced by Qingdao Ocean Chemical Factory). With chloroform, acetone gradient elution. The effluent was examined by silica gel thin-layer chromatography detection (color development with dilute sulfuric acid). The target liquid was collected, concentrated under reduced pressure, and dried in vacuo. Add a small amount of ethanol to dissolve the residue, filter, and then concentrate the filtrate under reduced pressure and dry it in vacuo to obtain the product. After testing, the content of Glabrid...

Embodiment 3

[0022] First dry and pulverize the licorice glabra, then put the crushed licorice glabra and methylene chloride into a reflux heating device according to the ratio of 1:7, heat and reflux together for 6 hours, filter and wash. Repeat twice, combine the filtrate and washings, concentrate, recover the solvent, and dry under reduced pressure to obtain the residue, which is the crude product I.

[0023] Or put the Glycyrrhiza glabra powder and ethyl acetate into the percolation device according to the ratio of 1:7, and percolate. When the colorless liquid flows out (about 10 hours), the solvent is recovered, and the residue is vacuum-dried , to obtain crude product II.

[0024] The crude product I and crude product II obtained above were ground, dissolved in a small amount of chloroform, and the solution was carefully added to a pre-treated silica gel column filled with silica gel (the silica gel was produced by Qingdao Ocean Chemical Factory). With chloroform, acetone gradient e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com