Method of producing piezoelectric ceramic device

A manufacturing method and technology of piezoelectric ceramics, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, printed circuit manufacturing, piezoelectric/electrostrictive transducers, etc., can solve the problem of lower insulation resistance and lower voltage characteristics And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

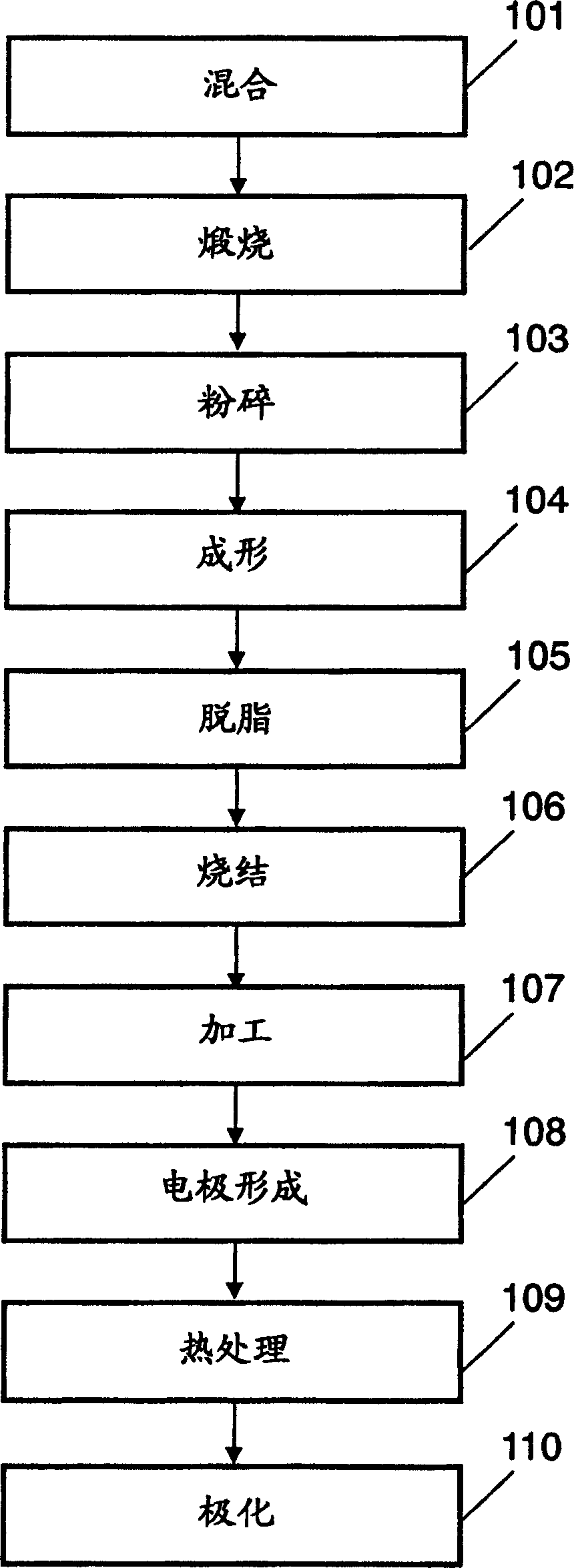

[0022] FIG. 1 shows a manufacturing process of a piezoelectric ceramic composition used in a piezoelectric ceramic device according to Embodiment 1 of the present invention. The basic formula for weighing and matching is Pb(Zn 1 / 3 Nb 2 / 3 ) a Zr x Ti y o 3 Piezoelectric ceramic composition materials lead oxide (PbO), titanium oxide (TiO 2 ), zirconia (ZrO 2 ), zinc oxide (ZnO), niobium oxide (Nb 2 o 5 ) powder, so that the molar ratio of the respective metal elements becomes the composition of Fig. 2. These powders are put into a ball mill simultaneously with water and partially stabilized zirconia balls as a medium, and the ball mill is rotated for 20 hours for wet mixing (step 101). at this time. The weight ratio of material and water is 1:1, and the particle size of the medium zirconia is less than or equal to 5mm.

[0023] Next, the slurry obtained by wet-mixing the above-mentioned powders was transferred to a container having a flat bottom such as a stainless ta...

Embodiment approach 2

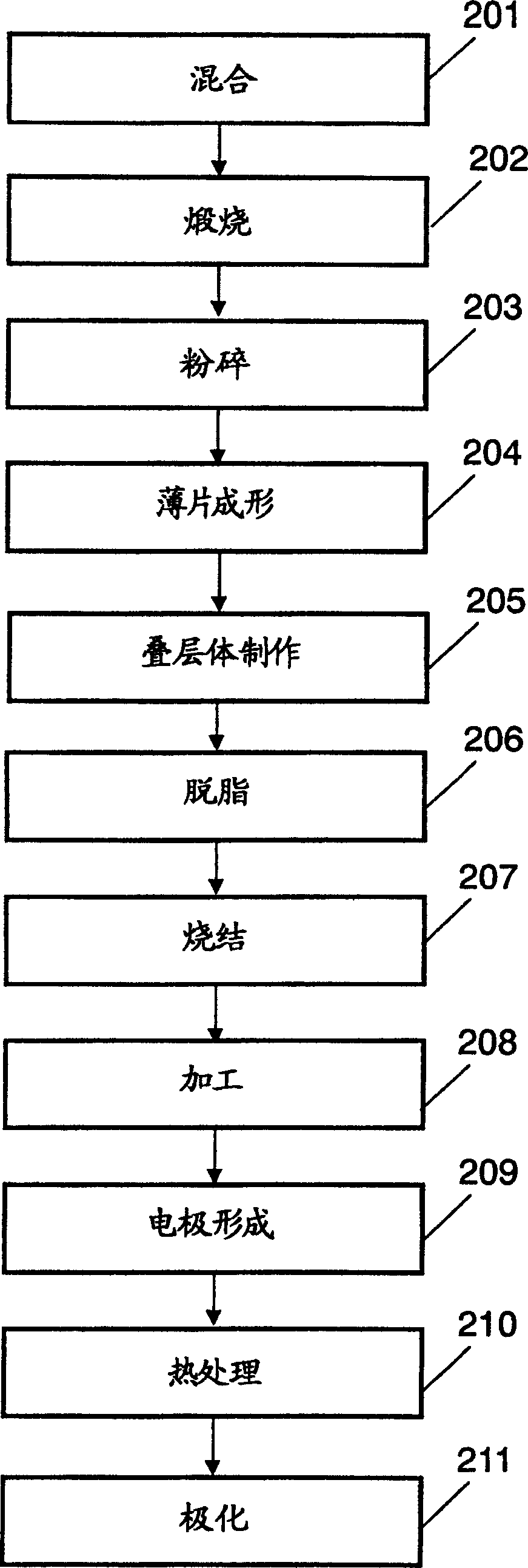

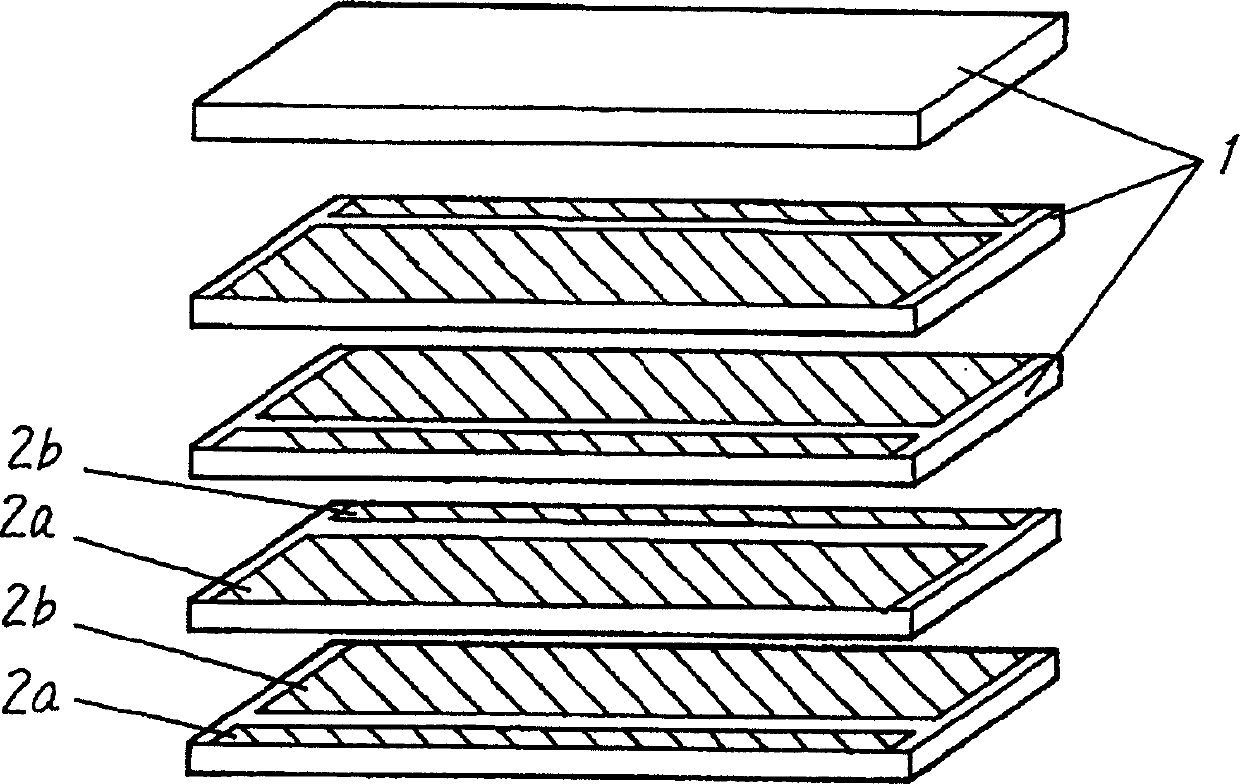

[0052] FIG. 6 shows a manufacturing process of the piezoelectric ceramic composition used in the piezoelectric ceramic device according to Embodiment 2 of the present invention. 7 is an exploded perspective view of a laminated piezoelectric actuator of the piezoelectric ceramic device in Embodiment 2, and FIG. 8 is a perspective view of the actuator.

[0053] In Embodiment 2, as an element having a laminated structure in which the amount of expensive palladium (Pd) used can be reduced, inexpensive internal electrodes containing 95% or more of Ag and a piezoelectric ceramic composition are simultaneously sintered, laminated layers are laminated. Electric actuators have been researched, and a method of manufacturing a piezoelectric ceramic composition that has stable insulation resistance even when used under high temperature and high humidity has been studied.

[0054] First, weigh and mix lead oxide (PbO), titanium oxide (TiO 2 ), zirconia (ZrO 2 ), zinc oxide (ZnO), niobium...

Embodiment approach 3

[0077] The manufacturing process of the piezoelectric ceramic composition used in the piezoelectric ceramic device in Embodiment 3 is the same as that in Embodiment 1 shown in FIG. 1 .

[0078] First, weigh and mix lead oxide (PbO), titanium oxide (TiO 2 ), zirconia (ZrO 2 ), zinc oxide (ZnO), niobium oxide (Nb 2 o 5 ), manganese dioxide (MnO 2 ) powder, so that the molar ratio of each metal element becomes the composition shown in Figure 12. Then, according to the process of Embodiment 3, except that the material contains MnO 2 Other than that, it is the same as Embodiment 1, so the following steps are omitted.

[0079] Next, evaluation results of samples of piezoelectric ceramic elements obtained according to the manufacturing process of Embodiment 3 are shown. Figures 12 to 15 measure the insulation resistance of the sample before polarization in step 110, and the insulation resistance after the humidity resistance storage test placed at high temperature (120°C), high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com