Concentrated sample introduction method for realizing trace components for chromatograph

A technology for trace components and chromatograph, which is applied in the field of chromatograph to realize the concentration and sampling of trace components, and can solve the problems of inability to analyze solid samples, broadening of sampling bands, and inability to concentrate trace components, etc. Wide range of samples and the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] operating conditions

[0020] Gas chromatography column: HP-5, 30m×0.32mm×0.25μm

[0021] Detector: FID, temperature 250°C

[0022] Column temperature: programmed temperature increase at 35°C, hold for 0min, then increase temperature to 300°C at 15°C / min

[0023] Injector: split injection, split ratio 1:1, temperature 250°C

[0024] Sample: Particulate matter in the exhaust gas of internal combustion engines (contains a large amount of carbon and trace amounts of saturated hydrocarbons, aromatic hydrocarbons and other substances that pollute the environment)

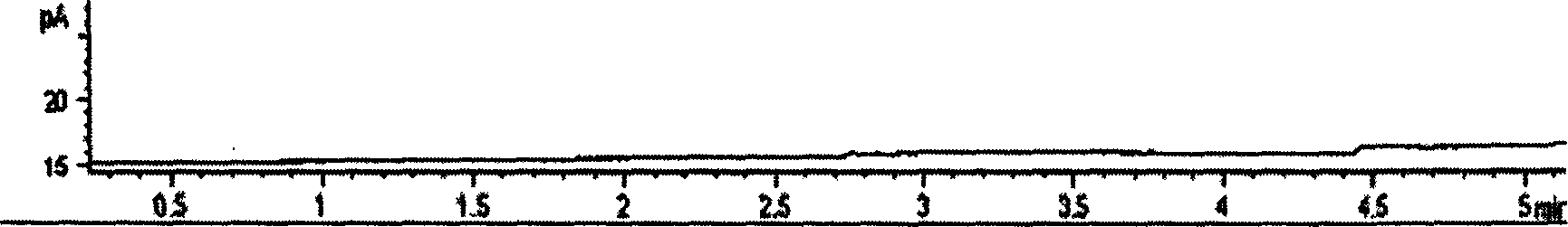

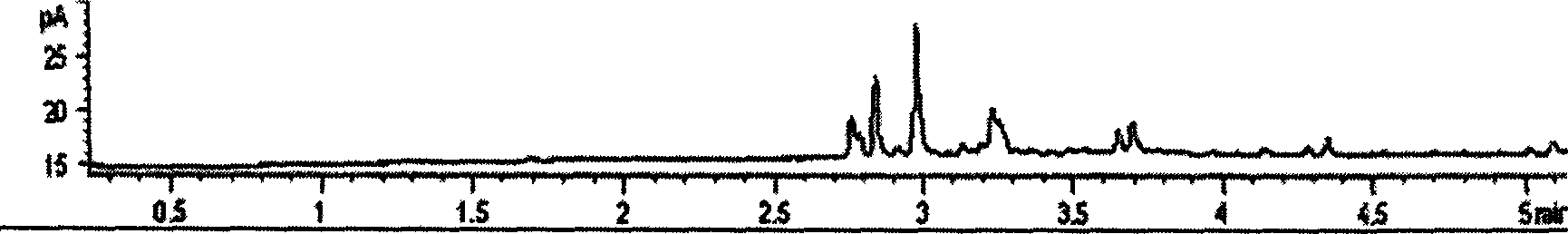

[0025] Analysis by conventional headspace technology: first heat treatment of glass fiber filter paper at 600°C for 5 hours, and then capture particulate matter in exhaust gas of internal combustion engine. Put the filter paper with trapped particles into the headspace balance device, keep the temperature at 280°C for 30 minutes, purge and trap the balance gas, and directly inject samples for analysis. No volat...

Embodiment 2

[0028] operating conditions

[0029] Gas chromatography column: HP-5, 12m×0.22mm×0.25μm

[0030] Detector: MS (mass spectrometry), temperature 185°C

[0031] Column temperature: program temperature rise to 70°C for 2 minutes, then increase temperature to 280°C at 25°C / min

[0032] Injector: Split injection, split ratio 1:20, temperature 250°C

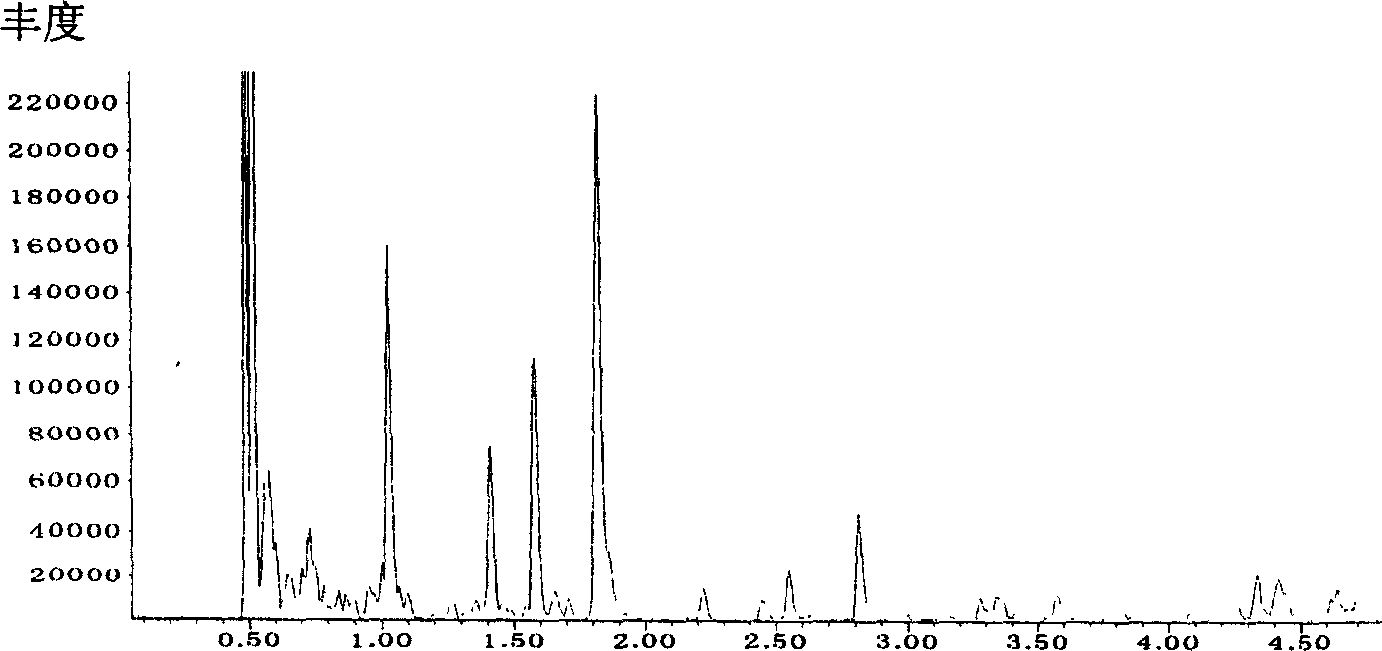

[0033] Sample: Natural Rubber and Butadiene Rubber Blend

[0034]Put a small amount of powdered rubber sample into the reactor and carry out the cracking reaction at a high temperature of 800 ° C for 5 minutes, and the gas components generated by the cracking reaction are continuously sent to the secondary concentration device. At this time, the temperature of the secondary concentration device is -30°C, and the reaction gas produced by cracking is continuously concentrated. After the cracking reaction is completed, the temperature of the secondary concentration device is increased to 280°C, and the concentrated reaction gas compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com