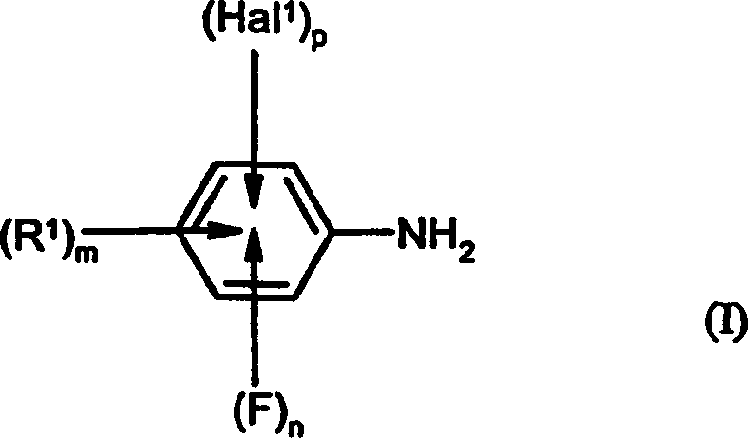

Preparation of fluorinated anilines

A compound, azobenzene technology, applied in the field of preparing fluorinated aniline, can solve problems such as unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

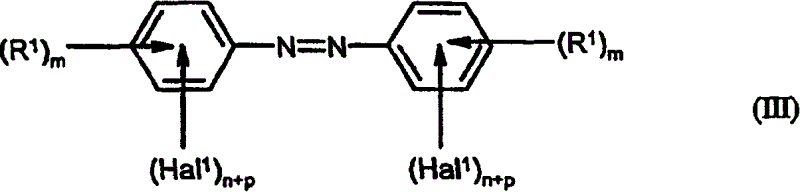

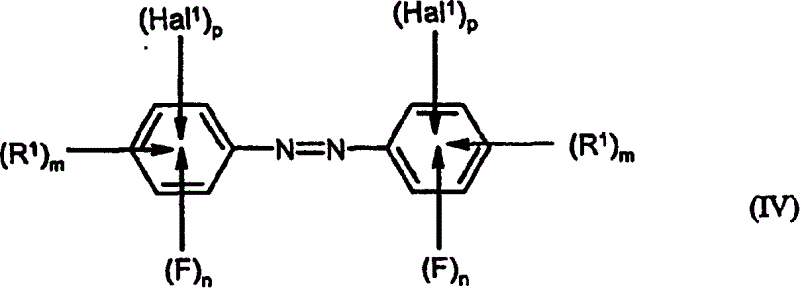

[0076] Preparation of 2,2',4,4',6,6'-hexafluoroazobenzene

[0077] In the absence of moisture, initially 4.3 g of dry potassium fluoride and 3.0 g of 2,2',4,4',6,6'-hexachloroazobenzene were added to 51 g of sulfolane, and 0.2 g of bromide Tetraphenylphosphonium. Subsequently, the mixture was heated to 180° C. and stirred for 12 hours. After cooling, the mixture was drained into 150 ml of water and extracted twice with 50 ml of cyclohexane (each). After crystallization, 1.7 g (76% of theory) of the desired product were obtained.

Embodiment 2

[0079] Preparation of 2,4,6-trifluoroaniline

[0080] 2,2',4,4',6,6'-hexafluoroazobenzene of 1.0g Example 1 was dissolved in 20ml methanol at room temperature, and 0.6g ammonium formate and 0.5g zinc powder were added continuously. The mixture was stirred at room temperature for 1 hour. The starting material was completely converted by GC analysis. After methanol had been distilled off, 2,4,6-trifluoroaniline was extracted in cyclohexane and dried, and the solvent was distilled off again. This leaves 0.9 g of the desired product (89% of theory).

Embodiment 3

[0082] Preparation of 2,2'-bis(trifluoromethyl)-4,4'-difluoroazobenzene

[0083] In the same manner as in Example 1, 9.8 g of 2,2'-bis(trifluoromethyl)-4,4'-dichloroazobenzene, 4 g of potassium fluoride and 0.5 g tetraphenylphosphonium bromide was reacted for 15 hours. After crystallization, 5.8 g of 2,2'-bis(trifluoromethyl)-4,4'-difluoroazobenzene (65% of theory) were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com