Laser irradiation apparatus, laser irradiation method, and method for manufacturing crystalline semiconductor film

A technology of laser irradiation and manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, lighting devices, semiconductor devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

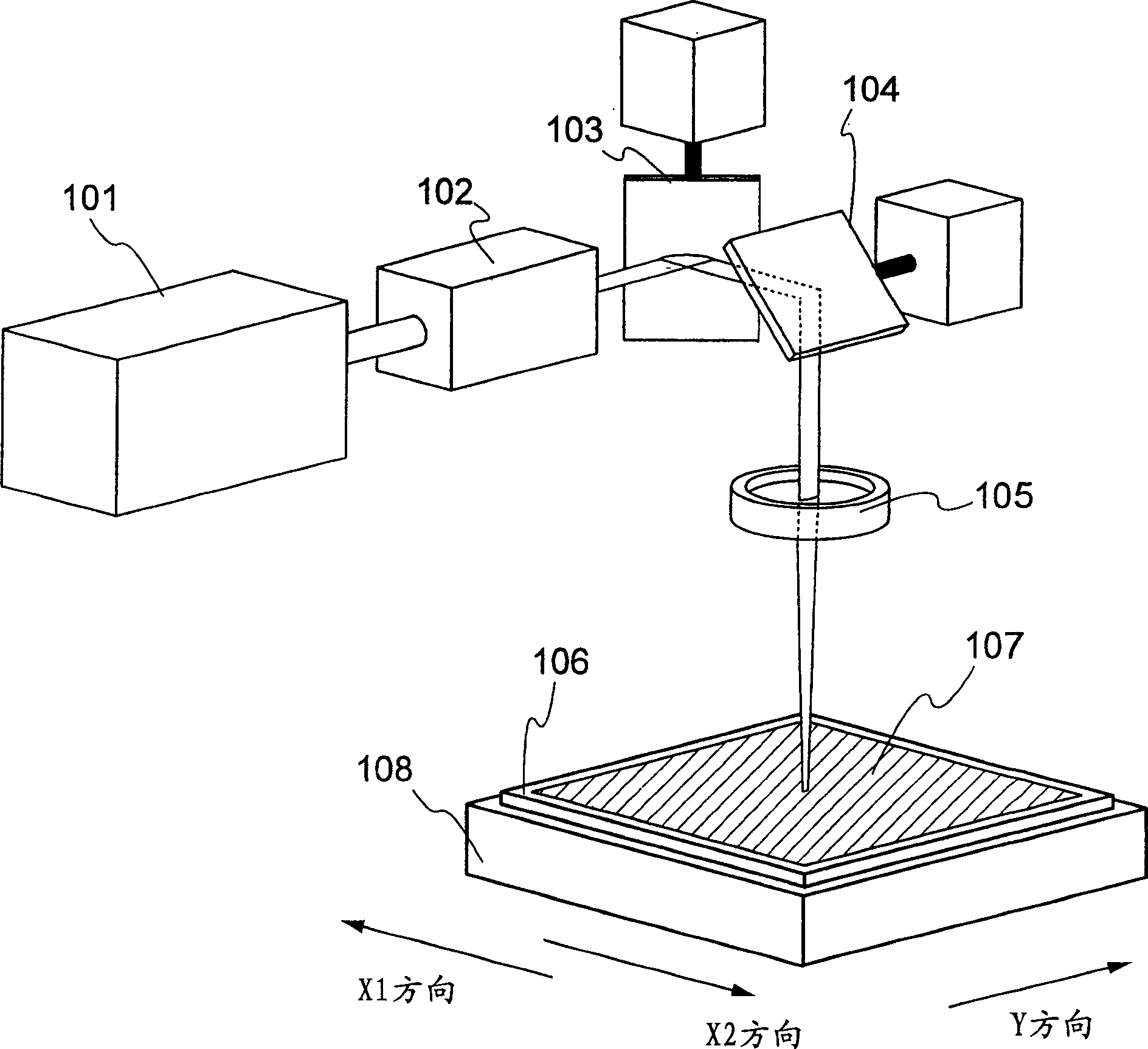

[0157] This example will refer to figure 1 Examples of the present invention will be described.

[0158] 101 denotes a laser oscillator for pulse oscillation, which is a laser oscillator capable of oscillating laser light with a pulse width of picosecond level or less. Any laser can be used for the laser oscillator of the present invention as long as it can oscillate an extremely short-pulse laser beam of 10 psec or less. For example, excimer lasers, Ar lasers, Kr lasers, CO 2 Laser, YAG laser, Y 2 o 3 Laser, YVO 4 Laser, YLF laser, YAlO 3 Laser, GdVo 4 Lasers, ceramic lasers, glass lasers, ruby lasers, alexandrite lasers, Ti:sapphire lasers, copper vapor lasers, or gold vapor lasers, etc.

[0159] This example uses 2W YVO 4 laser. The laser oscillator incorporates a nonlinear optical element, and emits laser light with a wavelength of 532nm at the second harmonic of the laser light, which has a high absorption rate for the amorphous silicon film. It is desirable t...

Embodiment 2

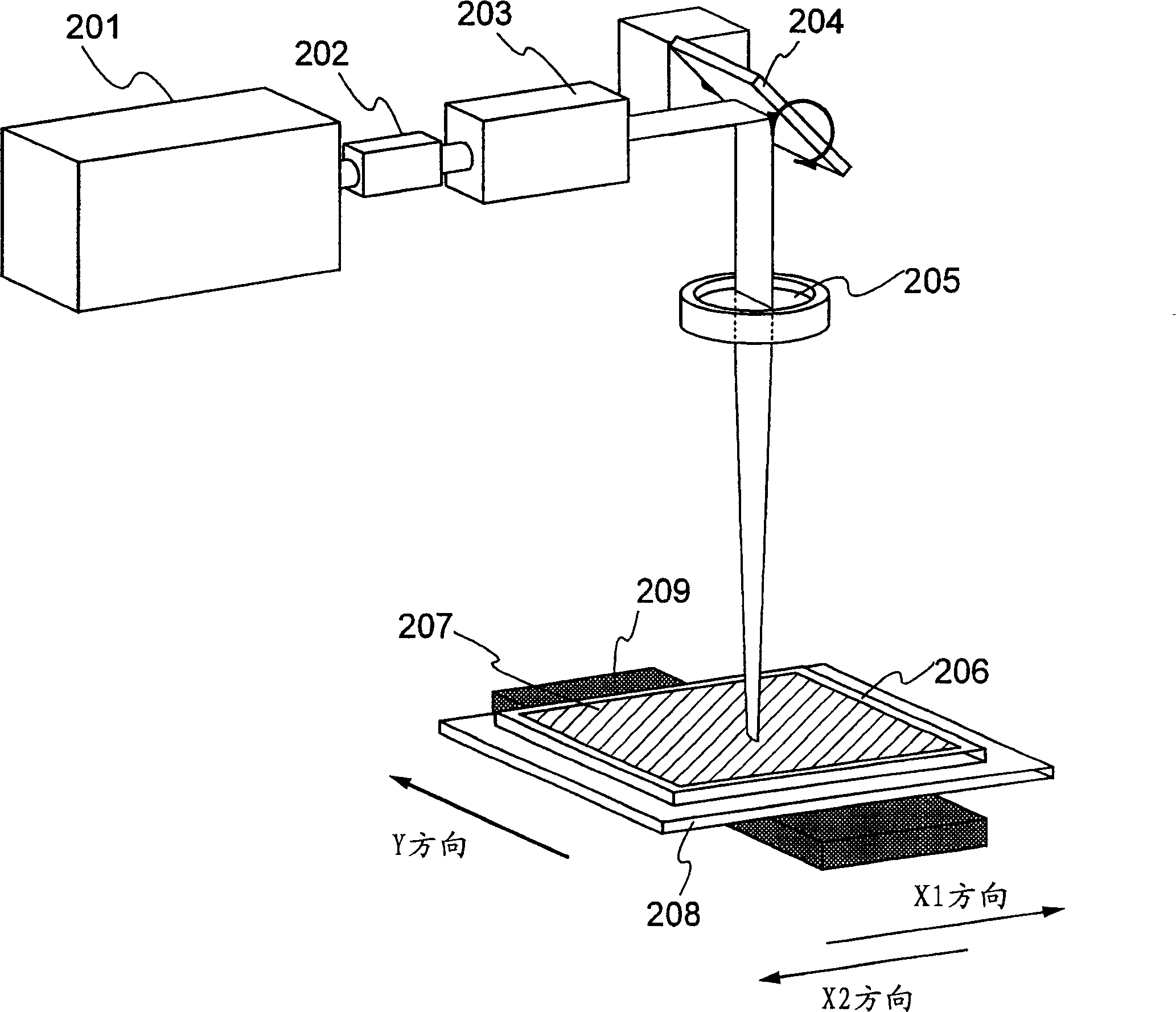

[0174] This example will refer to image 3 An example of a laser irradiation device including a laser oscillator 201 that oscillates laser light with a pulse width of picosecond level or below; an electric mirror 204 driven in one direction; an fθ lens 205 is described. ; The stage 208 and the mobile robot 209 moving in one direction.

[0175] A laser beam output from a laser oscillator 201 is converted into a second harmonic wave by a nonlinear optical element 202 and shaped into an arbitrary shape by an optical system 203 . In this embodiment, the configuration of the optical system 203 is such that the shape of the beam spot on the irradiation surface is formed into a line shape. Thereafter, the semiconductor film 207 formed on the glass substrate 206 is scanned with a linear laser beam (X1 direction) using the galvanic mirror 204 and the fθ lens 205 . Note that, in the case of using a linear beam, laser irradiation can be efficiently performed if the minor axis direction...

Embodiment 3

[0180] This example will refer to Figure 4 Another embodiment mode of the present invention will be described. In this embodiment, an example will be described in which laser crystallization is performed only on a position where a TFT is formed in an amorphous semiconductor film formed on a substrate.

[0181] The laser oscillator 401 is a laser oscillator capable of oscillating a laser beam of an extremely short pulse at or below the picosecond level. A laser beam with a pulse width of 10 psec, a wavelength of 532 nm, an output power source of 8 W, a repetition frequency of 80 MHz, and a beam diameter of 0.6 mm was oscillated from this oscillator. The oscillated laser beam is shaped into an arbitrary shape by the optical system 402 . In this embodiment, the beam shape on the semiconductor film 408 formed on the substrate 407 on the irradiation surface is shaped by using a lenticular lens acting only in the uniaxial direction so that the beam shape becomes 300 μm in the maj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com