Application of bamboo extractive in heat processing food as acrylamide suppressor

A technology of bamboo leaf extract and acrylamide, which is applied in the fields of application, food preservation, and food science, and can solve the problems of no public reports on acrylamide research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

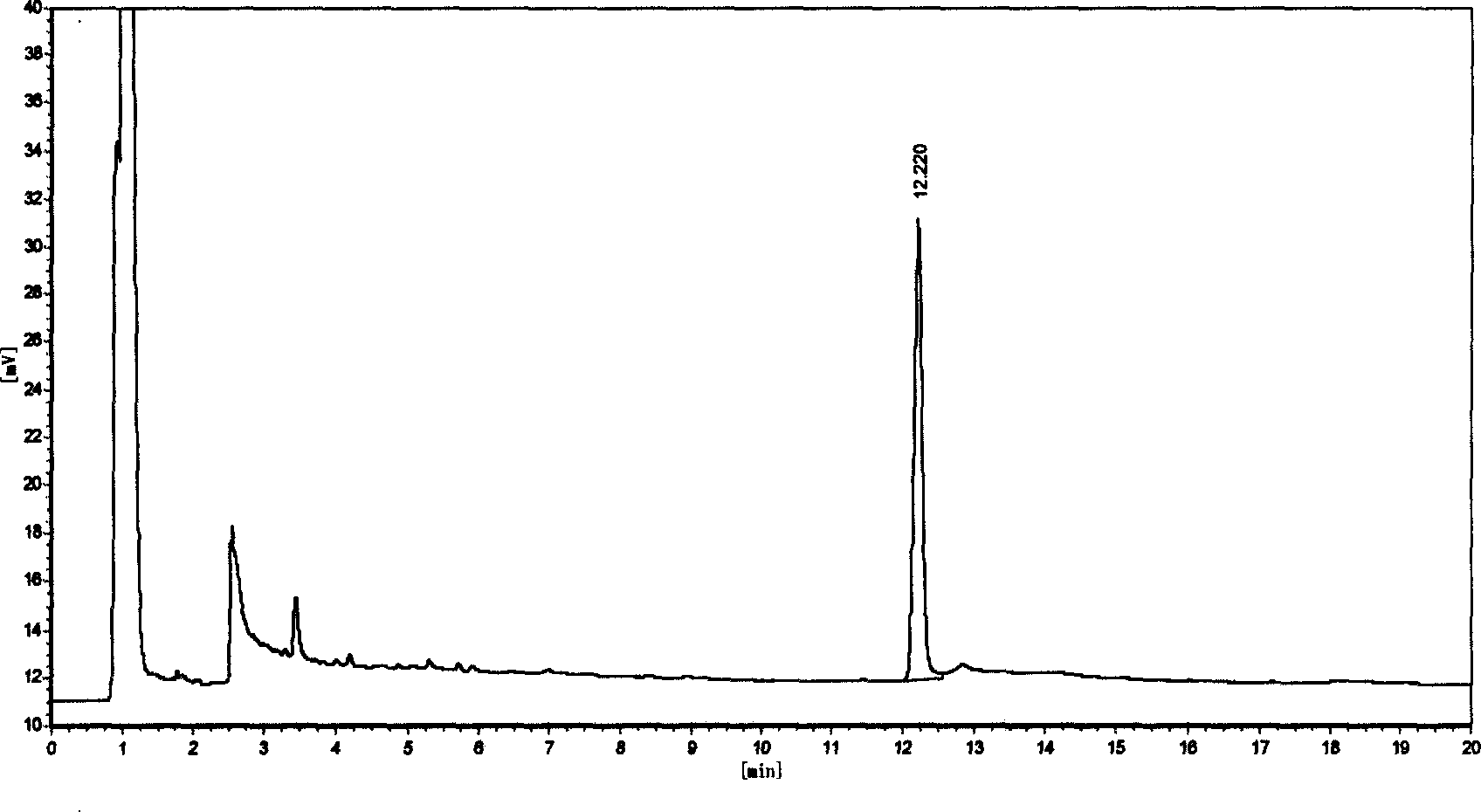

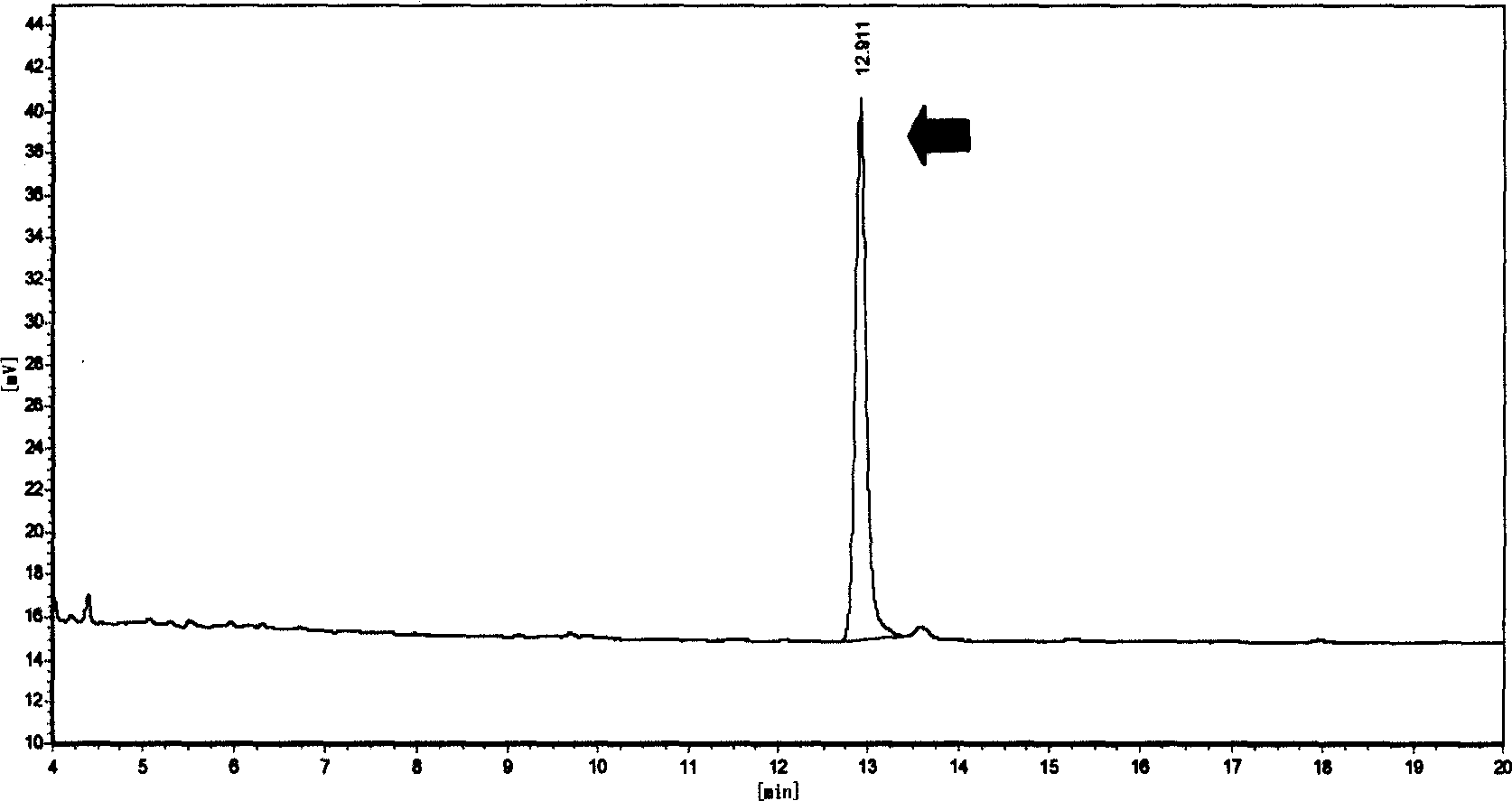

[0071] Embodiment 1, bamboo leaf extract produces the inhibition of acrylamide to simulated reaction system:

[0072] Take 0.1mol / L L-asparagine and D-glucose 10mL each and mix → place in a 100mL Erlenmeyer flask → set up a blank control group; add bamboo leaf extract on the basis of the above blank control group to make the final The concentration of bamboo leaf extract in the system is 10mg / kg test group 1 and 150mg / kg test group 2 → heat the blank control group, test group 1, and test group 2 in a water bath at 120°C for 15 minutes → directly obtained The reaction solution was then subjected to derivatization → GC analysis.

[0073] Wherein the specific process of derivatization reaction is as follows:

[0074] Take 20 μL each of the blank control group, test group 1, and test group 2→into a 20mL colorimetric tube→add 0.6mL 10% (v / v)H 2 SO 4 →Add water to make up to 10mL→Place in refrigerator at 4°C for 20min and pre-cool →Add 1.5g KBr powder to fully dissolve→Add 1mL 0....

Embodiment 2

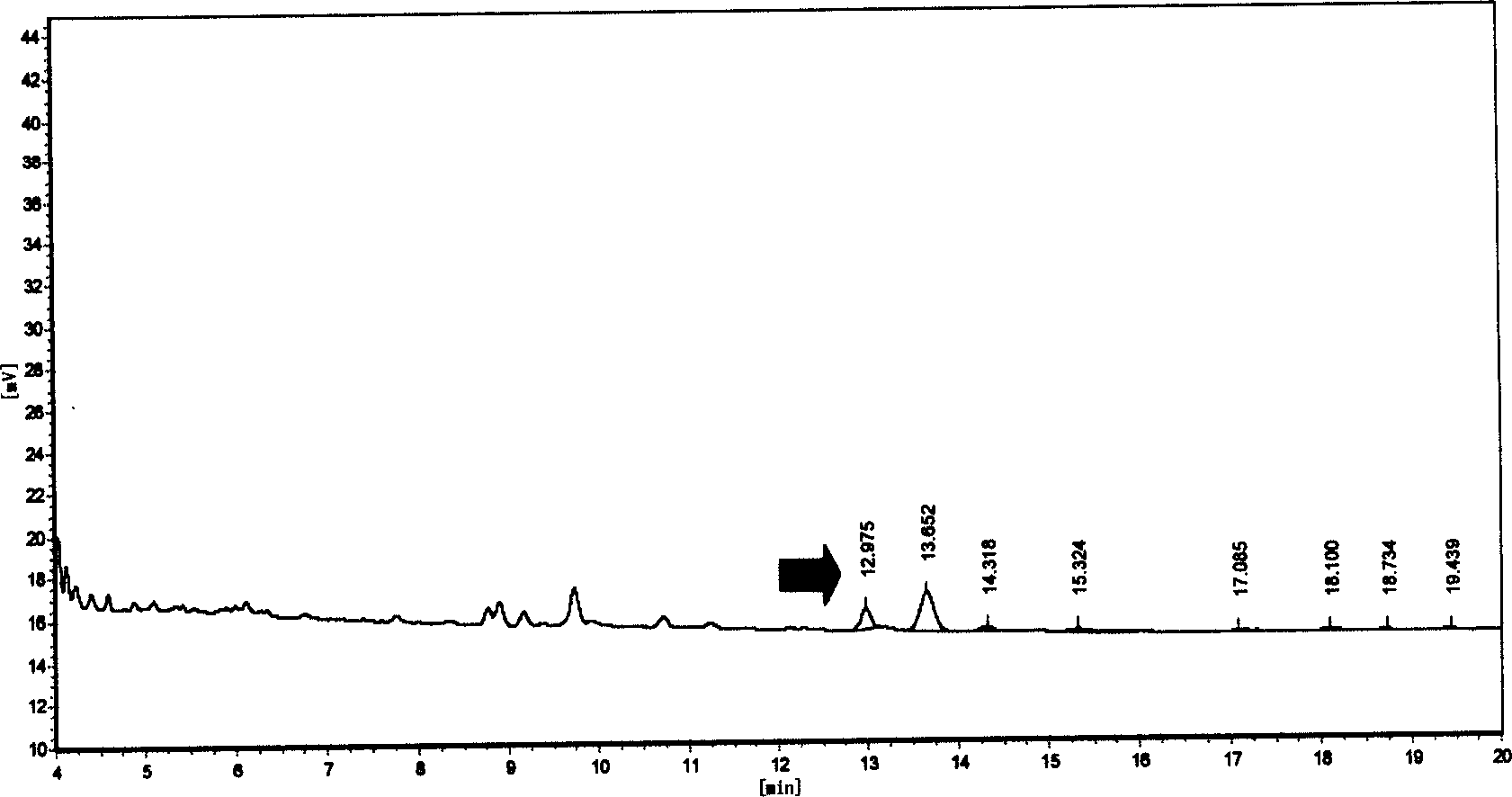

[0079] Embodiment 2, the inhibitory effect of different doses of bamboo leaf extracts on the simulated reaction system to produce acrylamide:

[0080]

[0081] It can be seen from Table 2 that when the amount of AOB added in the simulated reaction system is within the range of 1-9mg / kg, it has different degrees of inhibition on the acrylamide produced by the simulated reaction system, and the inhibition rate has a significant linear correlation.

Embodiment 3

[0082] Embodiment 3, bamboo leaf extract produce the inhibition of acrylamide to fried potato chips:

[0083] (1) potato chips

[0084] Fresh potatoes are cleaned, peeled and cut into thin slices with a thickness of about 1mm. The cut potato slices are selected, rinsed twice with running water, and dried with absorbent paper.

[0085] (2) Plant extracts

[0086] Bamboo leaf extract: a product produced by Hangzhou Zhedafu Biotechnology Co., Ltd. (the product code is EOB-C01), the total flavonoid content is 40.7%, and the total phenol content is 79.8%;

[0087] Tea extract: a water-soluble tea polyphenol preparation provided by the Tea Science Department of Zhejiang University, with a content of 98%.

[0088] (3) Experimental grouping

[0089] There are three groups in this experiment, which are blank control group A (potato slices are not treated with any solution), bamboo leaf extract dosage group B (potato slices are soaked in aqueous solution of bamboo leaf extract) and tea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com