Iron making process in blast furnace and additives therefor

A blast furnace ironmaking and additive technology, which is applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of unfavorable blast furnace intensified smelting, large addition amount, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

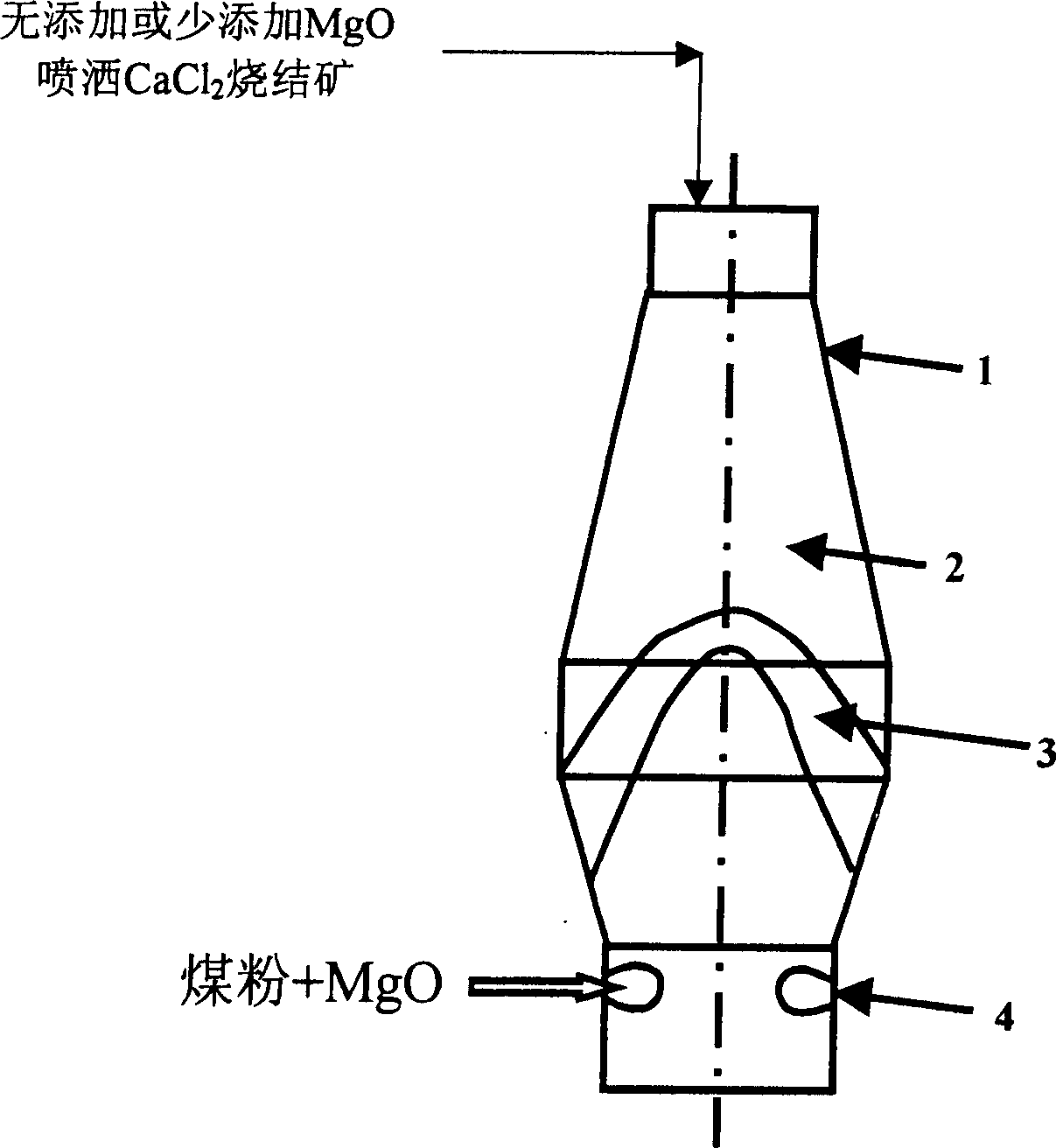

[0023] In a steel company 1800M 3 On blast furnace 1, control the content of MgO in the sinter to 0.9wt%, with 4.0wt% CaCl 2 Additives are sprayed on sintered ore at a rate of 4.5 kg / ton as raw material for blast furnace ironmaking. Utilize existing pulverizing injection system, the MgO-containing additive of following formula:

[0024] Composition Weight percent (wt%)

[0025] MgO 82.3

[0026] CaO 12.5

[0027] SiO 2 1.4

[0028] Burnout 3.8

[0029] It is fed into the coal mill together with the raw coal for pulverization, and the pulverized coal is sprayed into the blast furnace from the tuyere 4. The injection equivalent of MgO additive is 20 kg / ton of iron. The adoption of this process effectively increases the output of sintered ore, reduces the low-temperature reduction pulverization rate of sintered ore; improves the air permeability of the block zone 2 of the blast furnace, and reduces the pressure difference of the material column by 20kP...

Embodiment 2

[0031] at 1250M 3 Implementation of the process of the present invention on the blast furnace 1. Since the content of magnesium oxide in its sintered ore is 0.8wt%, so 4.0wt% CaCl 2 The aqueous solution is evenly sprayed on the surface of the sintered ore at 200° C. at a usage rate of 5 kg / ton according to the weight of the sintered ore, and then fed into the blast furnace 1 . The MgO-containing additive of the following formula is added again:

[0032] Composition Weight percent (wt%)

[0033] MgO 80

[0034] CaO 14

[0035] SiO 2 2

[0036] burnout 4

[0037] Together with the raw coal, put it into a coal mill to grind it into powder, and spray it into the blast furnace from the tuyere 4. The injection equivalent of the additive is 25 kg / ton of iron. It increases the combustion rate of pulverized coal before the tuyere by about 5%, and at the same time significantly improves the smelting intensity of the blast furnace and the quality of pig iron...

Embodiment 3

[0039] at 750M 3 Implementation of this process on the blast furnace 1. With 4.0wt% CaCl 2 The aqueous solution is evenly sprayed on the surface of the sintered ore (containing MgO 0.8wt%) below 200° C. according to the proportion of sintered ore weight 4.2 kg / ton, and then fed into the blast furnace. The MgO-containing additive of the following formula is added again:

[0040] Composition Weight percent (wt%)

[0041] MgCO 3 80

[0042] CaO 14

[0043] SiO 2 2

[0044] burnout 4

[0045] Add the pulverized coal together with the raw coal, and blow the pulverized coal into the blast furnace from the tuyere 4. The injection equivalent of MgO additive is 20 kg / t iron. The production efficiency of the blast furnace is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com