Supercritical fluid analog moving bed chromatograph of ternary area

A technology of supercritical fluid and simulated moving bed, which is applied in the field of supercritical fluid simulated moving bed chromatography device, can solve the problems of increased equipment investment and operating cost, strict safety requirements, flammability and explosion, and achieve high consumption, Chemically stable and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

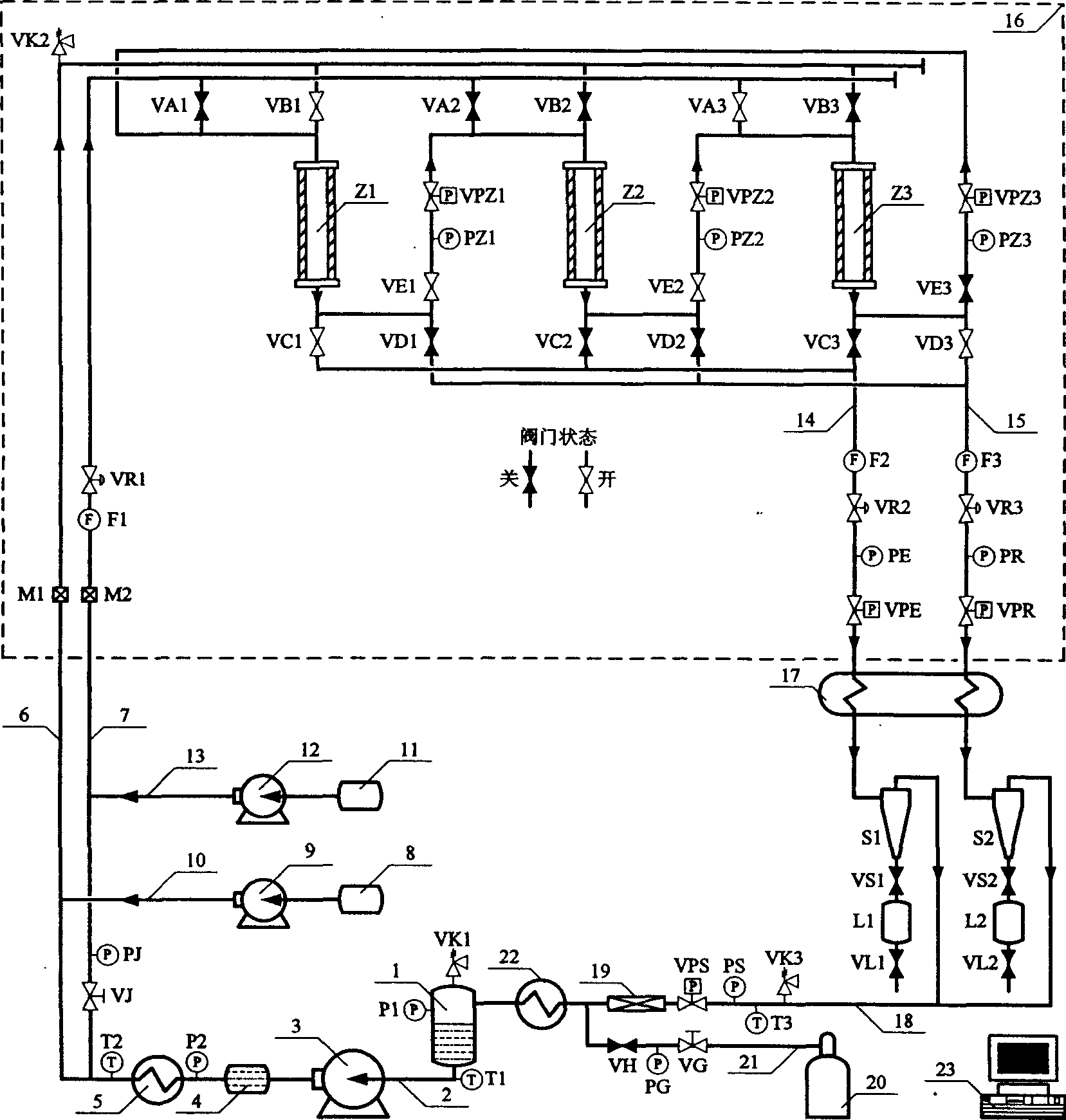

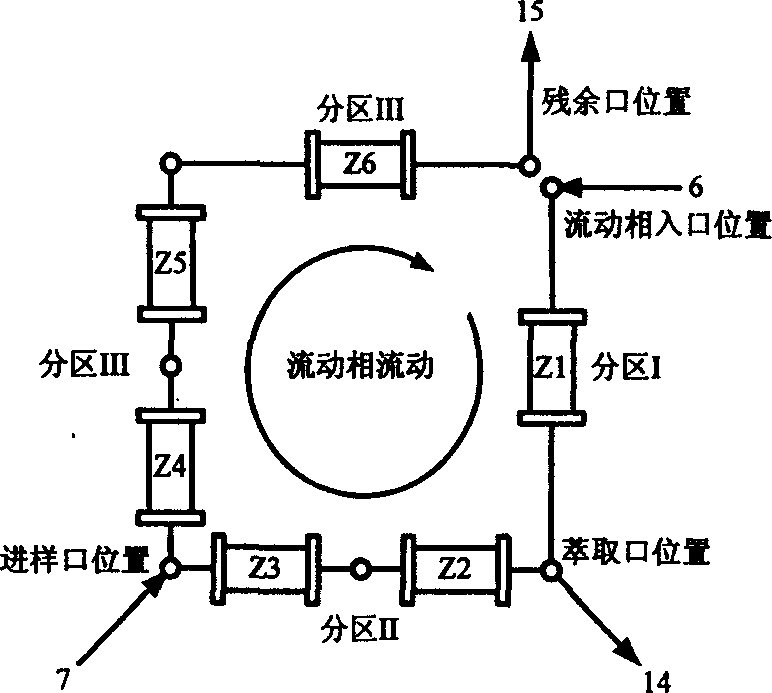

[0026] Such as figure 1 The shown three-section supercritical fluid simulated moving bed chromatographic device is equipped with only one packed column in each section, which is the most concise implementation form of the present invention. It includes three packed columns Z1, Z2, Z3, the outlet end of the first packed column Z1 is connected to the inlet end of the second packed column Z2 through the on-off valve VE1, the pressure sensor PZ1, the back pressure regulator VPZ1 in turn, and the The outlet end of the second packed column Z2 is connected to the inlet end of the third packed column Z3 through the switch valve VE2, the pressure sensor PZ2, and the back pressure regulator VPZ2 in turn, and the outlet end of the third packed column Z3 is sequentially passed through the switch Type valve VE3, pressure sensor PZ3, and back pressure regulator VPZ3 are connected to the inlet of the first packed column Z1; the inlets of each packed column Z1, Z2, and Z3 pass through their o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com