Etching composition and method for etching a substrate

An etching treatment and composition technology, applied in the field of etching compositions, can solve the problems of no etchant, not ideal, easy to catch fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

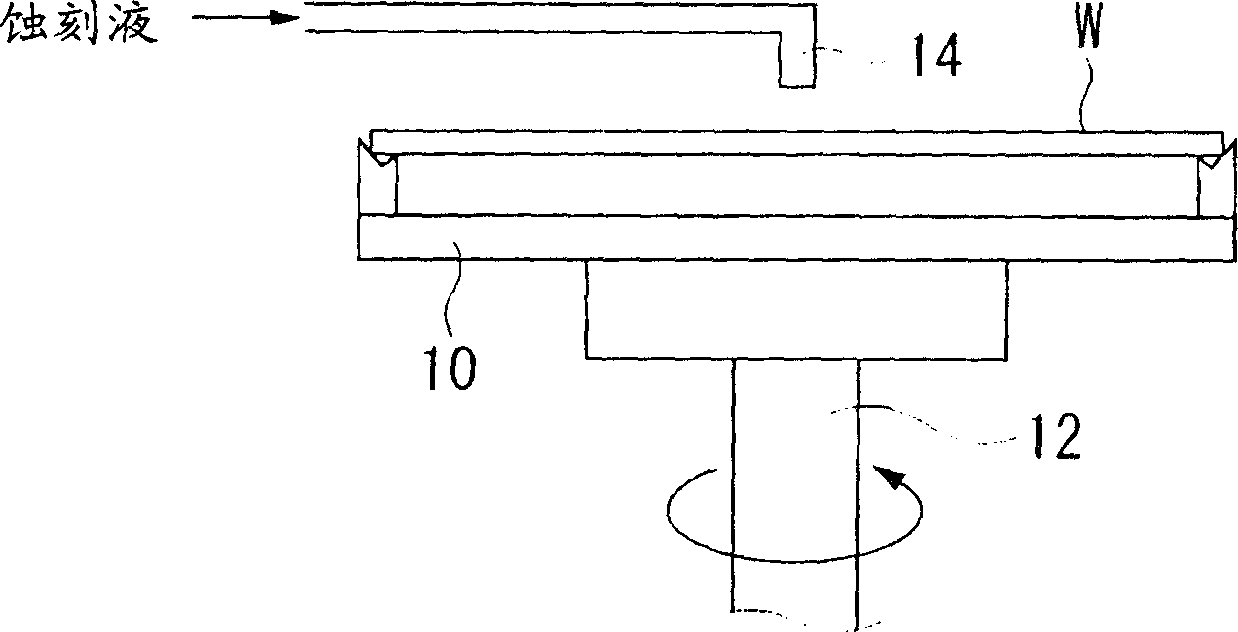

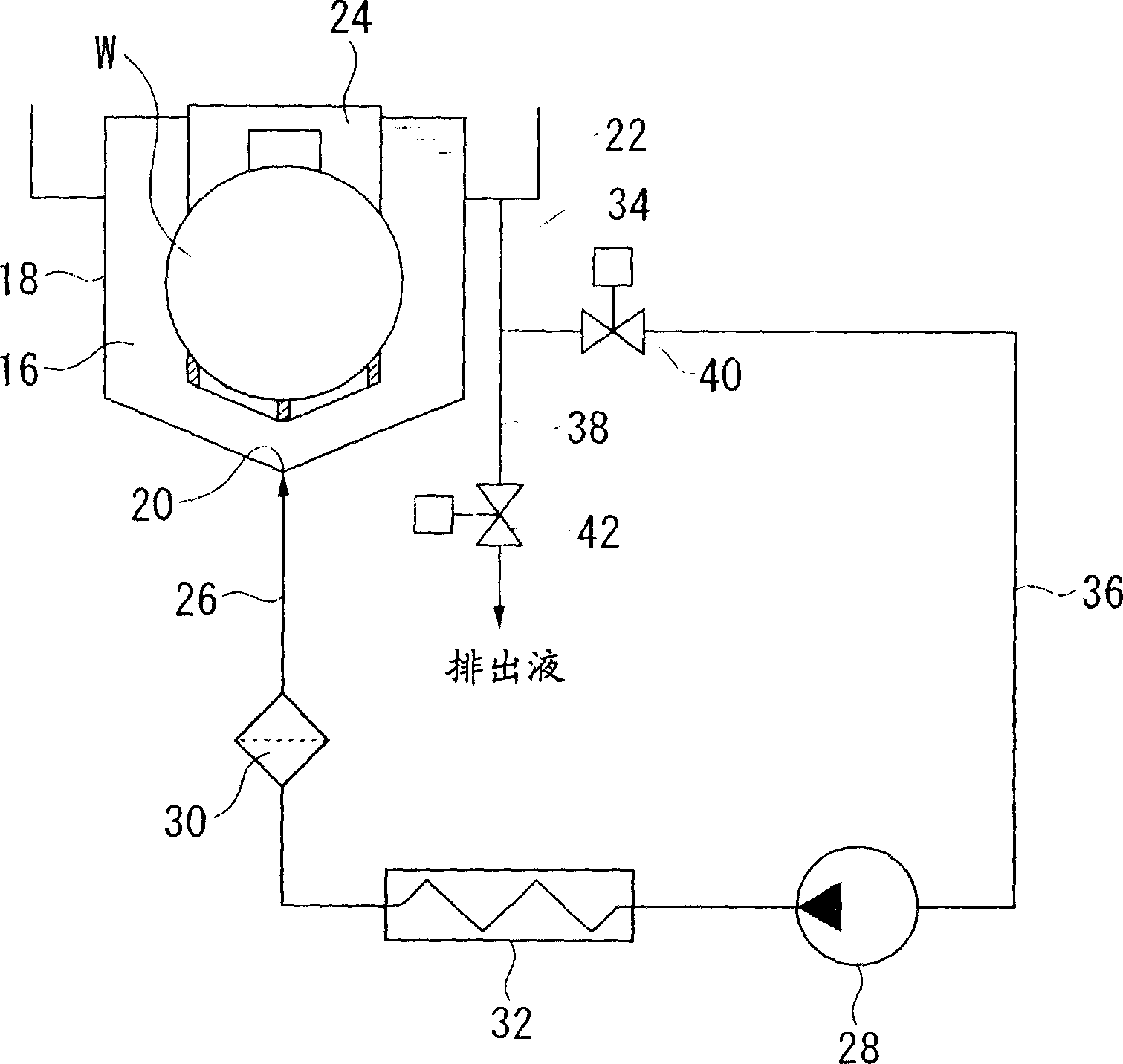

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~3

[0067] Use CVD (chemical vapor growth) method to make HfSiO x Or HfSiO x N y A silicon wafer substrate with a film thickness of 10nm is formed, and a thermal oxide film (SiO x ) A silicon substrate with a thickness of 300 nm and a silicon substrate with SiN formed with a thickness of 100 nm are formed. In addition, the etching compositions described in Table 1 were prepared, and each etching composition was put into a polyethylene container. In the etching composition of Table 1, the remainder is water.

[0068] Etching solution composition (wt%)

Temperature ℃

Etching speed (nm / min)

Additives

HfSiOx

HfSiONx

SiOx

SiN

Example 1

AF(0.1)

HCl(10)

80

1.096

1.034

0.120

Example 2

AF(0.1)

HCl(10)

40

0.674

0.880

0.172

Example 3

AF(0.1)

HCl(10)

25

0.384

0.514

0.122

Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com