Reinforced hollow fiber super filter film and its preparing method

An enhanced, ultrafiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as broken wires, affecting filtration accuracy and flux, and broken pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Put 500g of polyvinylidene fluoride resin in a jar, add 120g of polyvinylpyrrolidone and 2000ml of dimethylacetamide, heat to 70°C, stir evenly, seal and stand for defoaming.

[0035] Control the humidity of the casting film chamber at 45% relative humidity, and control the temperature of the casting chamber at 20°C, soak the clean hollow glass fiber in the casting solution for 8 seconds, and remove the infiltrated glass fiber from the 2mm diameter scraping hole Pull it out, evaporate at 30°C for 10 seconds, immerse it in a water bath at 20°C to form a film, and take it out to dry after 1 hour of gelling, to obtain the ultrafiltration membrane of the present invention.

[0036] According to the conventional performance evaluation method, the membrane's rejection rate of bovine serum protein is 95%, and the pure water flux is 1.8m under the conditions of 20℃ and 0.1Mpa pressure difference. 3 / hr m 2 .

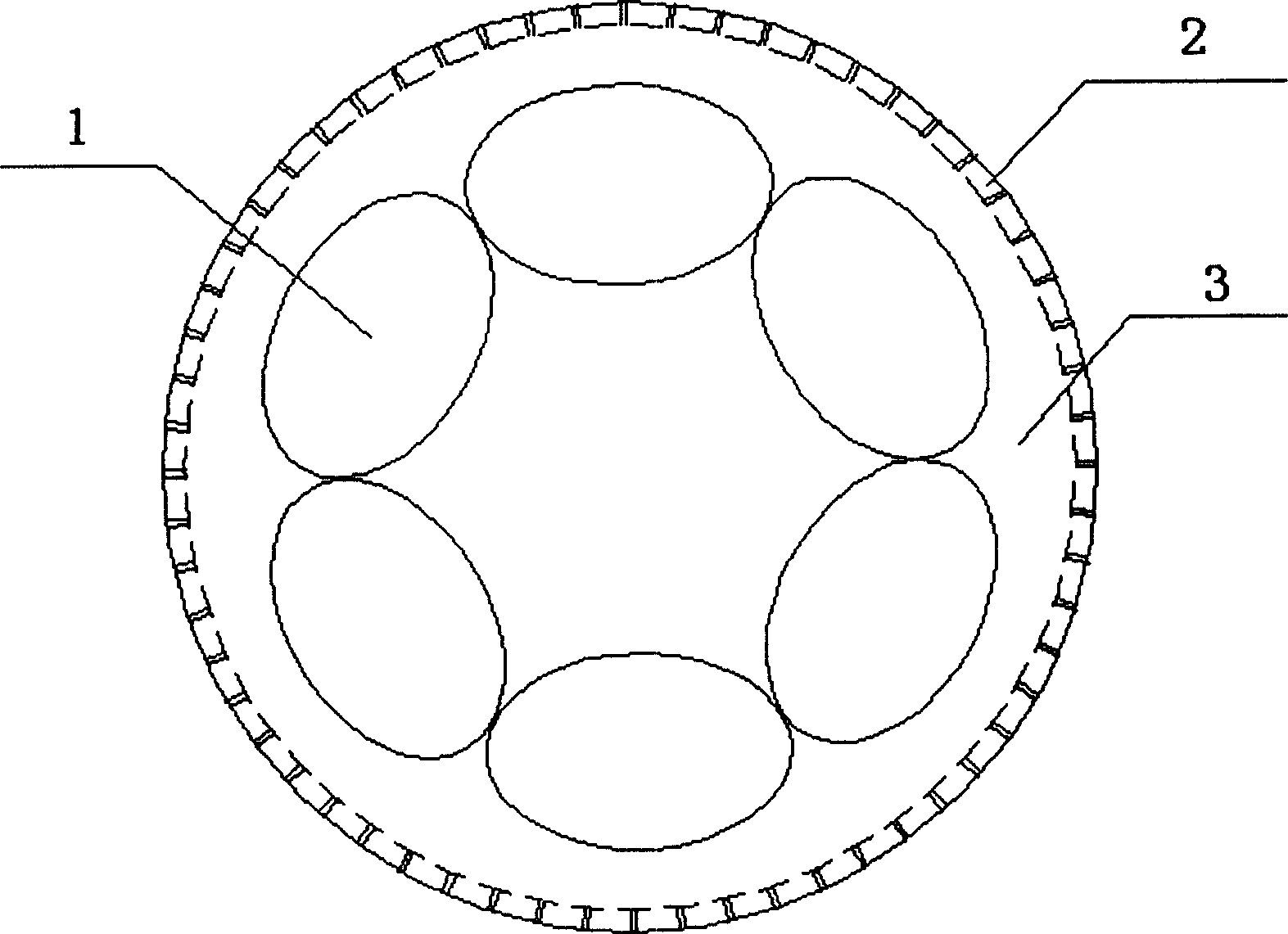

[0037] The electron microscope photos are as figure 1 , The structure d...

Embodiment 2

[0039] Put 500g of polyvinylidene fluoride resin in a jar, add 115g of polyvinylpyrrolidone, 15g of lithium nitrate, and 2250ml of dimethylacetamide, heat to 40°C, stir evenly, seal and stand for defoaming.

[0040] Control the humidity of the casting chamber at 45% relative humidity, and the temperature of the casting chamber at 20°C, soak the clean hollow glass fiber in the casting solution for 5 seconds, and remove the infiltrated glass fiber from the 1.8mm diameter scraping hole After being evaporated for 5 seconds, it is immersed in an ethanol aqueous solution with a weight concentration of 10% at 20°C to form a film, and the gel is taken out to dry after 1.5 hours to obtain the ultrafiltration membrane of the present invention.

[0041] Other conditions are the same as in Example 1.

[0042] According to the conventional performance evaluation method, the membrane's rejection rate of bovine serum protein is 91%, and the pure water flux is 2.2m3 / hr m2 at 20°C and 0.1MPa diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com