Thin 7YSZ, interfacial layer as cyclic durability (spallation) life enhancement for low conductivity tbcs

An anti-peeling and high-performance technology, applied in the direction of plating, coating, layered products, etc. of superimposed layers, which can solve the problems of low thermal conductivity coefficient and low thermal conductivity of TBC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

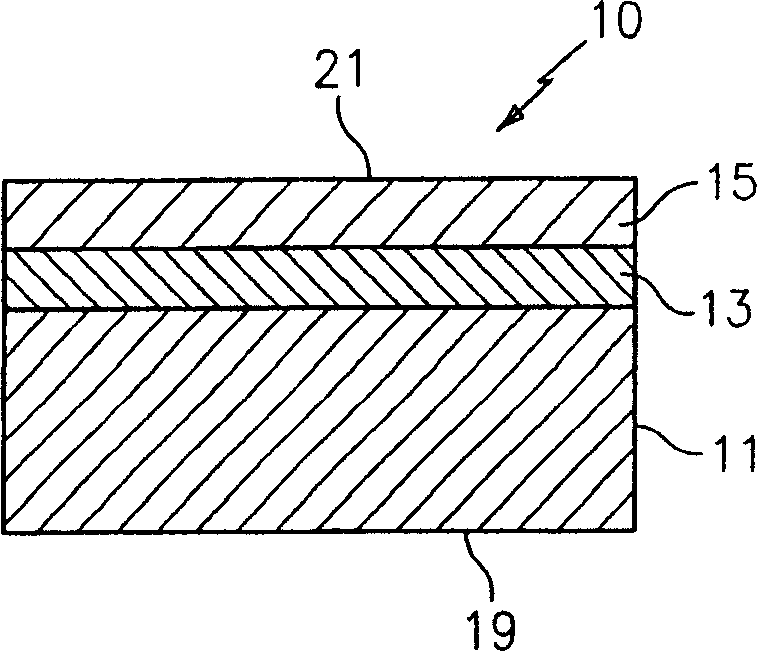

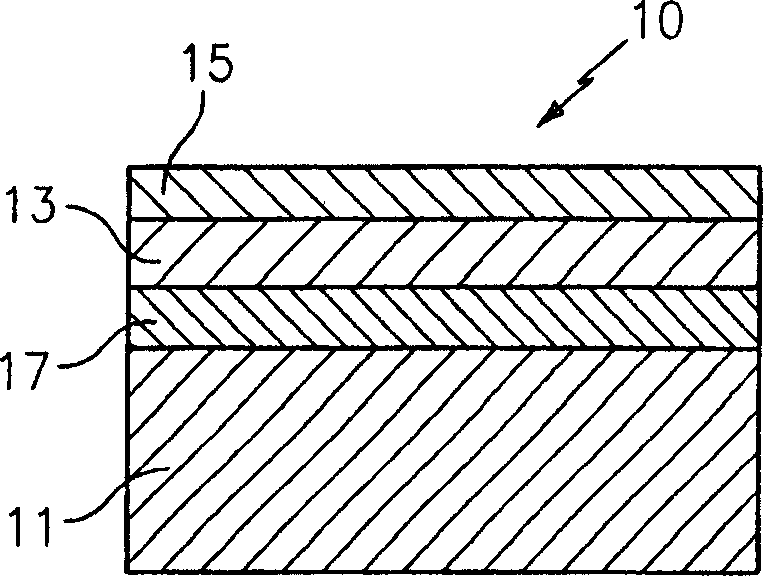

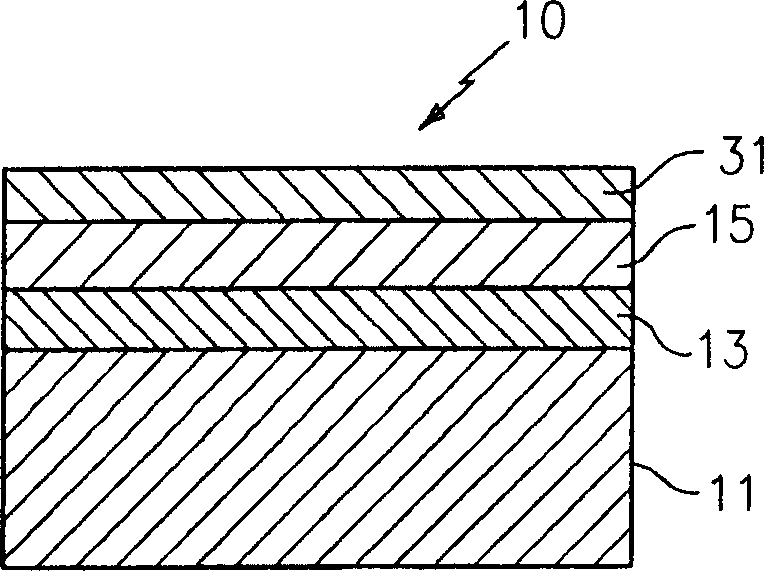

[0022] Accordingly, the teaching of the present invention is to provide a metal article, preferably a gas turbine engine component, having a metal substrate, comprising a ceramic thermal barrier coating (TBC) and a ceramic bond layer of stabilized zirconia interposed between the ceramic TBC and the metal substrate. A preferred ceramic bond layer is 7YSZ, although other yttria-stabilized zirconias, such as stabilized zirconias comprising about 1-20% by weight yttria. In all cases, ceramic TBCs consist of a zirconia base with additions of one or more of the following elements: La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc , In, Y, Mo and C, rare earth oxides, scandium and indium, wherein these elements are present in an amount of 1-50 of M2O3 oxide, and preferably 2-40 mol%, wherein M refers to the elements listed above . Yttria-stabilized zirconia (YSZ) exhibits ideal mechanical integrity, enabling it to withstand the stresses experienced when the metal article to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com