Process for preparing water soluble CdTe/CdS nuclear/shell type quantum point

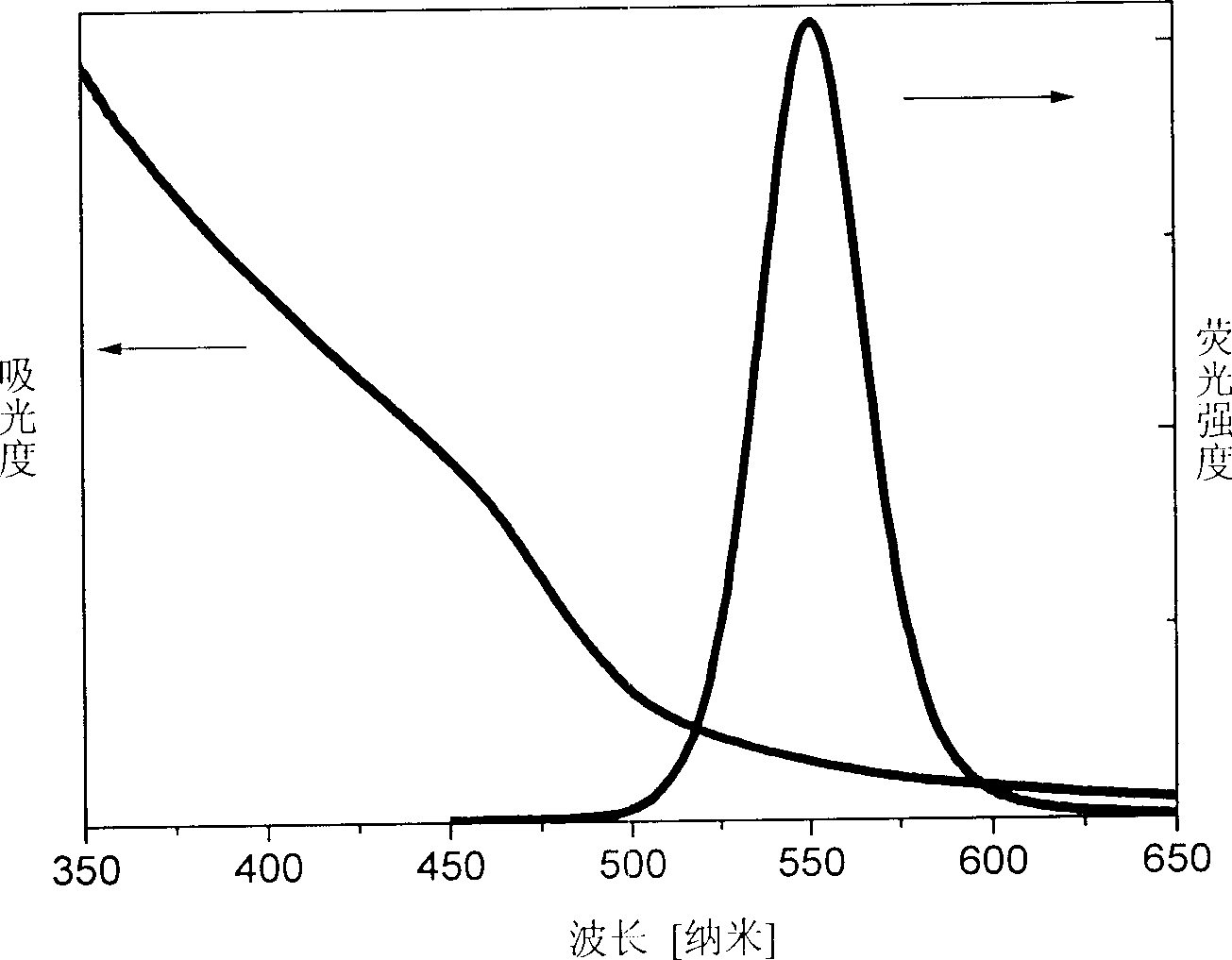

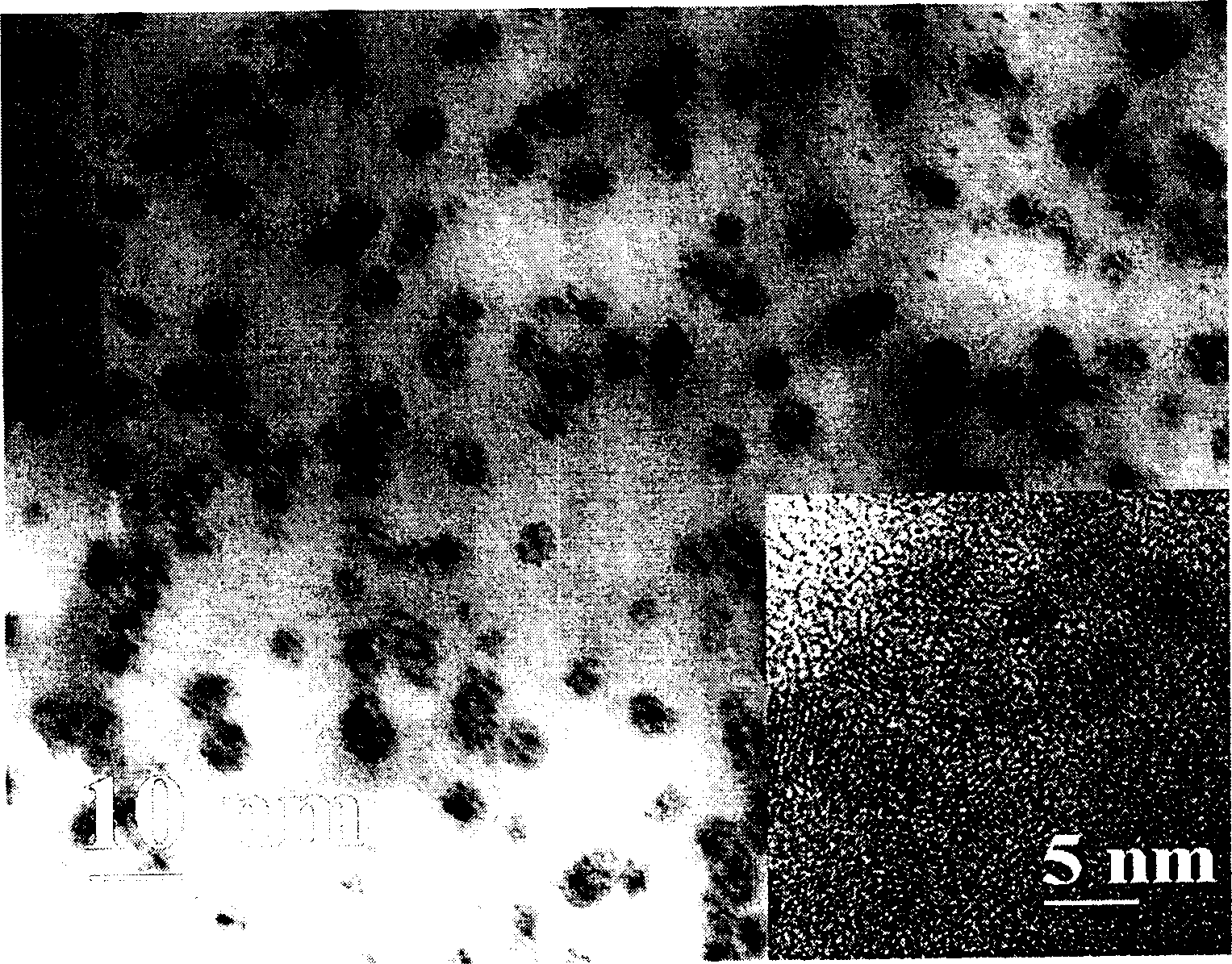

A quantum dot, water-soluble technology, applied in chemical instruments and methods, cadmium compounds, inorganic chemistry, etc., to achieve good monodispersity, low toxicity, fluorescence properties and improved quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Take 0.31g Na 2 SO 3 and 4.10mg of Se powder, placed in a 5ml single-necked flask, added 4ml of pure water, heated to 90°C under nitrogen protection, and reacted for 20 hours to obtain Na 2 SeSO 3 solution.

[0019] 2. Mix 10ml 2.4×10 -3 mol / LMPA+1.0×10 -3 mol / LCdCl 2 Mix the solution, pass nitrogen to remove oxygen for 30 minutes, heat up to 100°C, inject 0.3ml Na 2 SeSO 3 solution. Stop heating and gradually cool down to room temperature to obtain a transparent solution of CdSeNCs. The solution glows orange under excitation at 365 nm.

[0020] 3. Prepare 100ml 4.8×10 -3 mol / LMPA+1.0×10 -3 mol / LCdCl 2 +0.8×10 -3 mol / LNa 2 S mixed solution, deoxygenated by nitrogen for 30 minutes, heated to 100°C, injected into the prepared 10ml CdSeNCs solution under vigorous stirring, kept reflux at 100°C for 24 hours, and obtained CdSe / CdS core / shell quantum dots.

Embodiment 2

[0022] 1. Take 1.5g Na 2 SO 3 and 21.5mg of Se powder, placed in a 25ml single-necked flask, added 15ml of pure water, heated to 100°C under nitrogen protection, and reacted for 35 hours to obtain Na 2 SeSO 3 solution.

[0023] 2. Mix 5ml 2.5×10 -2 mol / L MPA+1.0×10 -2 mol / L CdCl 2 Mix the solution, pass nitrogen to remove oxygen for 30 minutes, raise the temperature to 90°C, inject 1ml Na 2 SeSO 3 solution. Stop heating and gradually cool down to 15 °C to obtain a transparent solution of CdSeNCs.

[0024] 3. Prepare 100ml 1.0×10 -2 mol / L MPA+6.0×10 -3 mol / L CdCl 2 +2.5×10 -3 mol / L Na 2 The S mixed solution was passed through nitrogen to remove oxygen for 30 minutes, and the temperature was raised to 100°C, and 1.5ml of the prepared CdSeNCs solution was injected under vigorous stirring, and the reflux was maintained at 100°C for 50 hours to obtain CdSe / CdS core / shell quantum dots.

Embodiment 3

[0026] 1. Take 0.60g Na 2 SO 3 and 10.5mg of Se powder, placed in a 100ml single-necked flask, added 50ml of pure water, heated to 80°C under nitrogen protection, and reacted for 24 hours to obtain Na 2 SeSO 3 solution.

[0027] 2. Mix 15ml 2.8×10 -3 mol / L MPA+1.5×10 -3 mol / L CdCl 2 Mix the solution, pass nitrogen to remove oxygen for 30 minutes, heat up to 90°C, inject 5ml Na 2 SeSO 3 solution. Stop heating and gradually cool down to 30 °C to obtain a transparent solution of CdSeNCs.

[0028] 3. Prepare 100ml 6.0×10 -3 mol / L MPA+1.5×10 -3 mol / L CdCl 2 +1.0×10 -3 mol / L Na 2 S mixed solution, deoxygenated by nitrogen for 30 minutes, heated to 110°C, poured into the prepared 15ml CdSeNCs solution under vigorous stirring, kept reflux at 100°C for 48 hours, and obtained CdSe / CdS core / shell quantum dots.

[0029] According to the method of the present invention, water-soluble core / shell quantum dots with other types of stabilizers can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com