Method and equipment for separating butyl acetate from waste water of extractive spent phase in fermentation liquid of penicillin

A penicillin fermentation and butyl acetate technology, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of equipment blockage and high energy consumption, and solve the problems of high energy consumption and water phase reduction Effects of back-mixing and improving hydrodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

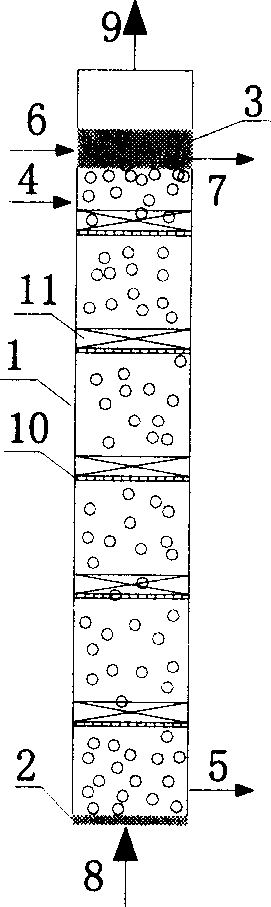

[0044] With an internal diameter of 10 cm, a glass tower 1 with a height of 2 m is used as the main body of the solvent air flotation tower, and a porous sintered titanium alloy plate with an average aperture of 10 microns and a diameter of 14 cm is used as a gas distributor 2 at the bottom of the tower with a flange. In the floating tower 1, 5 stainless steel sieve plates 10 with a plate spacing of 30cm are connected by threaded metal rods. The sieve plate 10 has a sieve hole diameter of 3-5mm, and waste water is opened at the upper and lower ends of the solvent air flotation tower body. The feed holes 4 and 5, and the inlet and outlet feed holes 6 and 7 of the solvent, the gas is pressed into the tower 1 through the gas distributor 2 under the pressure provided by the nitrogen or air cylinder.

Embodiment 2

[0046] With an internal diameter of 40cm and a height of 4m, the stainless steel tower 1 is used as the main body of the solvent air flotation tower, and a porous sintered plate with an average aperture of 10 microns and a diameter of 44cm is used as the gas distributor 2 at the bottom of the tower with a flange. A threaded metal rod connects 10 stainless steel sieve plates 10 with a plate spacing of 40cm. The aperture of the sieve plates 10 is 3-5mm. On each sieve plate, a layer of bulk packing or plate corrugated structured packing with a height of 3cm is placed. The upper and lower ends of the solvent air flotation tower are provided with waste water inlet and outlet holes 4 and 5, and solvent inlet and outlet holes 6 and 7, and the gas is pressed into the tower 1 through the gas distributor 2 under the pressure provided by the nitrogen or air cylinder.

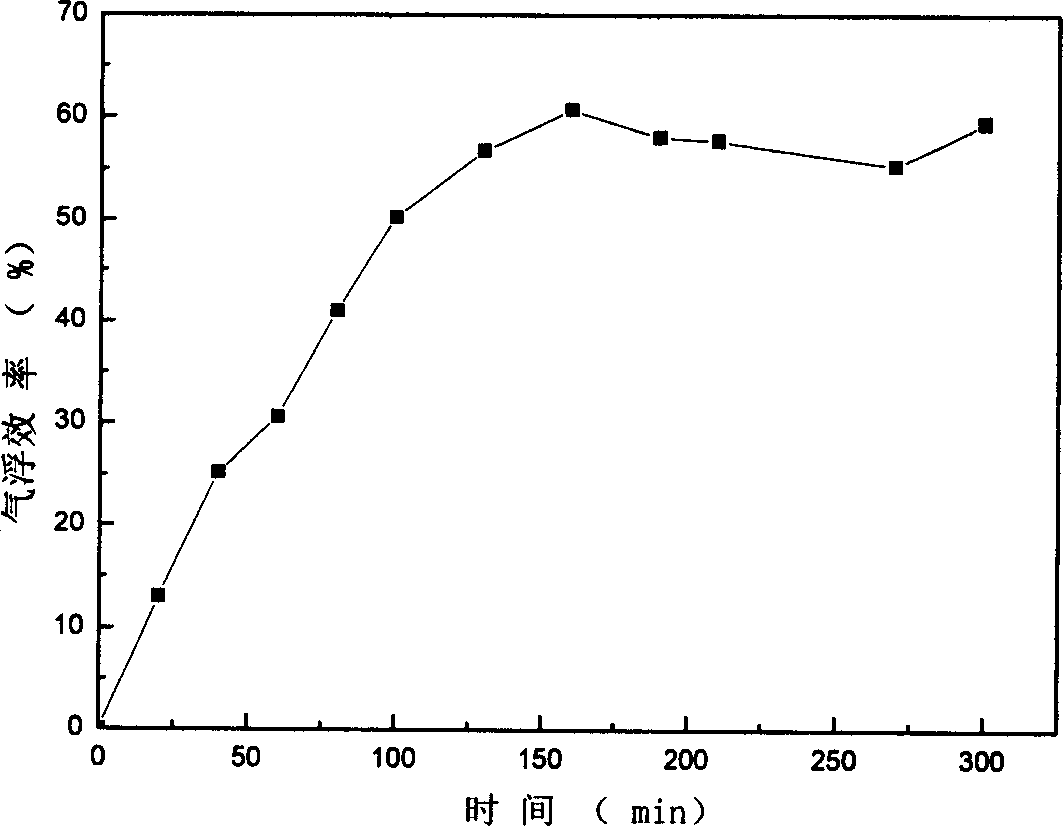

[0047] 2, embodiment 3~7 is to use solvent air flotation process to separate butyl acetate from penicillin fermentation l...

Embodiment 3

[0050] Embodiment 3, intermittent solvent air flotation process separation butyl acetate

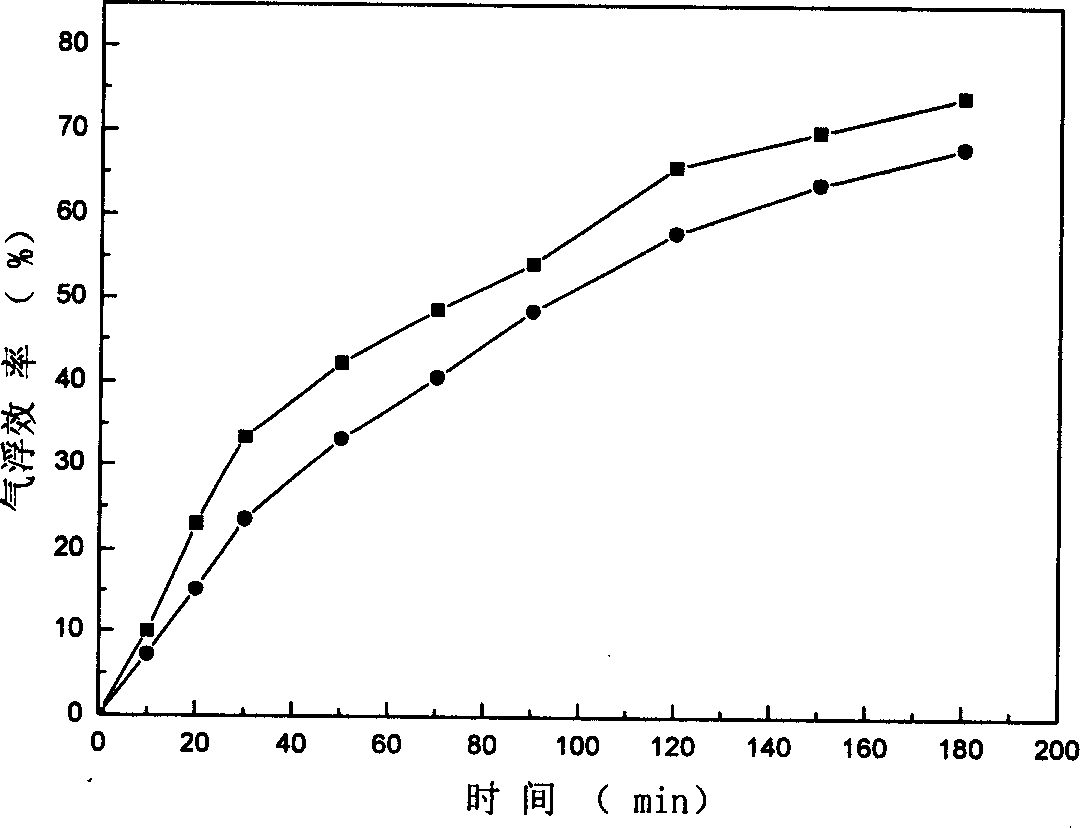

[0051] Add the penicillin fermentation liquid raffinate waste water 15L from the waste water inlet 4 of the solvent air flotation tower 1 that embodiment 1 makes, the pH=1~5 of this waste water, add 300ml isooctyl alcohol from the solvent inlet 6 above the waste water phase, Adjust the gas flow rate to 0.085cm / s, the pressure provided by the nitrogen or air cylinder is pressed into the tower 1 through the gas distributor 2, and the solvent air flotation operation is started. Neither the water phase nor the solvent phase enters and exits the material. Continued for 180 minutes, the butyl acetate in the penicillin fermentation liquid raffinate phase wastewater was separated from the water phase and enriched in iso-octanol; the solvent air flotation operation was stopped, and the iso-octanol in the upper layer of the water phase was collected. The experimental results were as follows: figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com