Technique for preparing saponin of gleditschia horrida and application

A saponin and process technology, applied in the preparation process of saponin and its application in pesticides, detergents, and shampoos, can solve the problems of complex process, large water treatment capacity, and large energy consumption, and achieve Reduce the cost of use, improve the effect of use, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

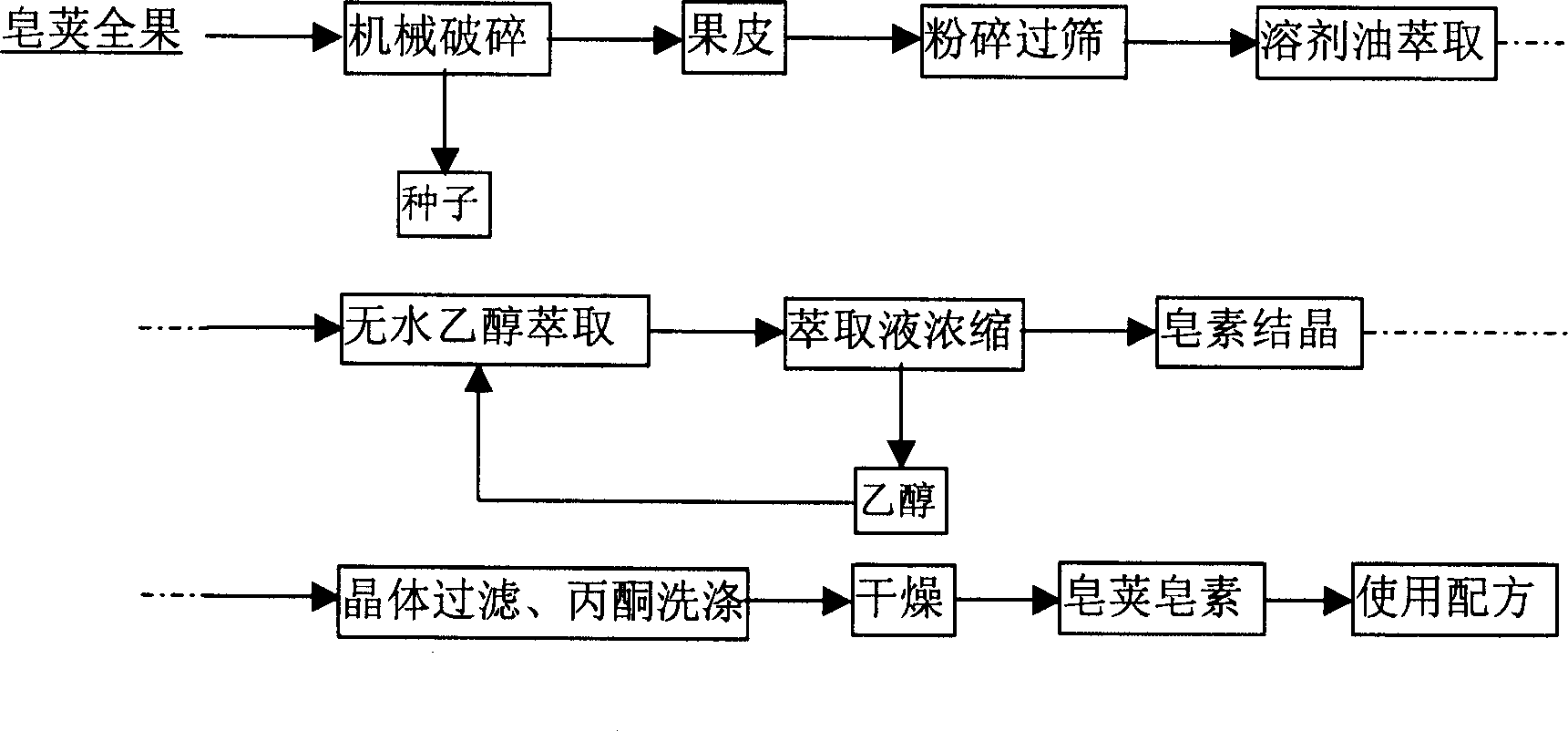

Image

Examples

Embodiment 1

[0050] Select the whole fruit of acacia with a water content of ≤8%. After cleaning and removing impurities, the impurity rate is ≤0.5%, and does not contain iron impurities; the whole fruit is mechanically crushed with a rod mill, and the seeds are separated, and the seed separation and extraction rate is ≥95% The acacia pericarp after the seeds are separated is pulverized and sieved by a hammer mill to obtain pericarp particles with a particle size of 2 to 3 mm. Use No. 6 extraction solvent oil (Jinling Petrochemical Co., Ltd.) to extract and separate the fat-soluble components in the pericarp. The weight ratio of the extractant to the pericarp is 3.5:1, and the extraction time is 5 hours. The defatted pericarp is extracted with absolute ethanol to separate saponin, the weight ratio of absolute ethanol and defatted pericarp is 4:1, the extraction temperature is 60° C., and the extraction time is 5 hours. The extract was concentrated until the weight ratio of saponin to ethan...

Embodiment 2

[0052] The acacia pericarp after the seeds are separated is pulverized and sieved by a hammer mill to obtain pericarp particles with a particle size of 0.5-2 mm. Use No. 6 extraction solvent oil (Jinling Petrochemical Co., Ltd.) to extract and separate the fat-soluble components in the pericarp. The weight ratio of the extractant to the pericarp is 7:1, and the extraction time is 6 hours. The defatted pericarp is extracted with absolute ethanol to separate saponin, the weight ratio of absolute ethanol and defatted pericarp is 8:1, the extraction temperature is 60° C., and the extraction time is 8 hours. The extract was concentrated until the weight ratio of saponin to ethanol was 1:1, and then crystallized at 15°C. The saponin crystals are filtered through a vacuum filter, washed twice with acetone and dried in a box dryer to obtain the saponin product. The calculated product yield, saponin purity and saponin extraction rate were measured respectively, and the results are sho...

Embodiment 3

[0054] The acacia pericarp after the seeds are separated is pulverized and sieved by a hammer mill to obtain pericarp particles with a particle size of 5-6mm. The fat-soluble components in the pericarp were extracted and separated with petroleum ether, the weight ratio of the extractant to the pericarp was 4:1, and the extraction time was 3 hours. The defatted pericarp is extracted with absolute ethanol to separate saponin, the weight ratio of absolute ethanol and defatted pericarp is 5:1, the extraction temperature is 60° C., and the extraction time is 4 hours. The extract was concentrated until the weight ratio of saponin to ethanol was 1:1, and then crystallized at 15°C. The saponin crystals are filtered through a vacuum filter, washed twice with acetone and dried in a box dryer to obtain the saponin product. The calculated product yield, saponin purity and saponin extraction rate were measured respectively, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com