Development of photolithographic masks for semiconductors

A technology of photoresist layer and development method, which is applied in the directions of optics, photography, and optomechanical equipment, can solve the problems of photoresist dumping, insufficient hardness, and increased capillary force of photoresist, etc. To achieve the effect of reducing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The process steps disclosed here start from photoresist development, and assume that the photoresist layer on the wafer has been patterned and exposed. The process steps disclosed in the present invention can be combined with an exposure light source with a wavelength lower than or equal to 193 nanometers, and are quite suitable for application in immersion lithography with an exposure wavelength lower than or equal to 248 nanometers.

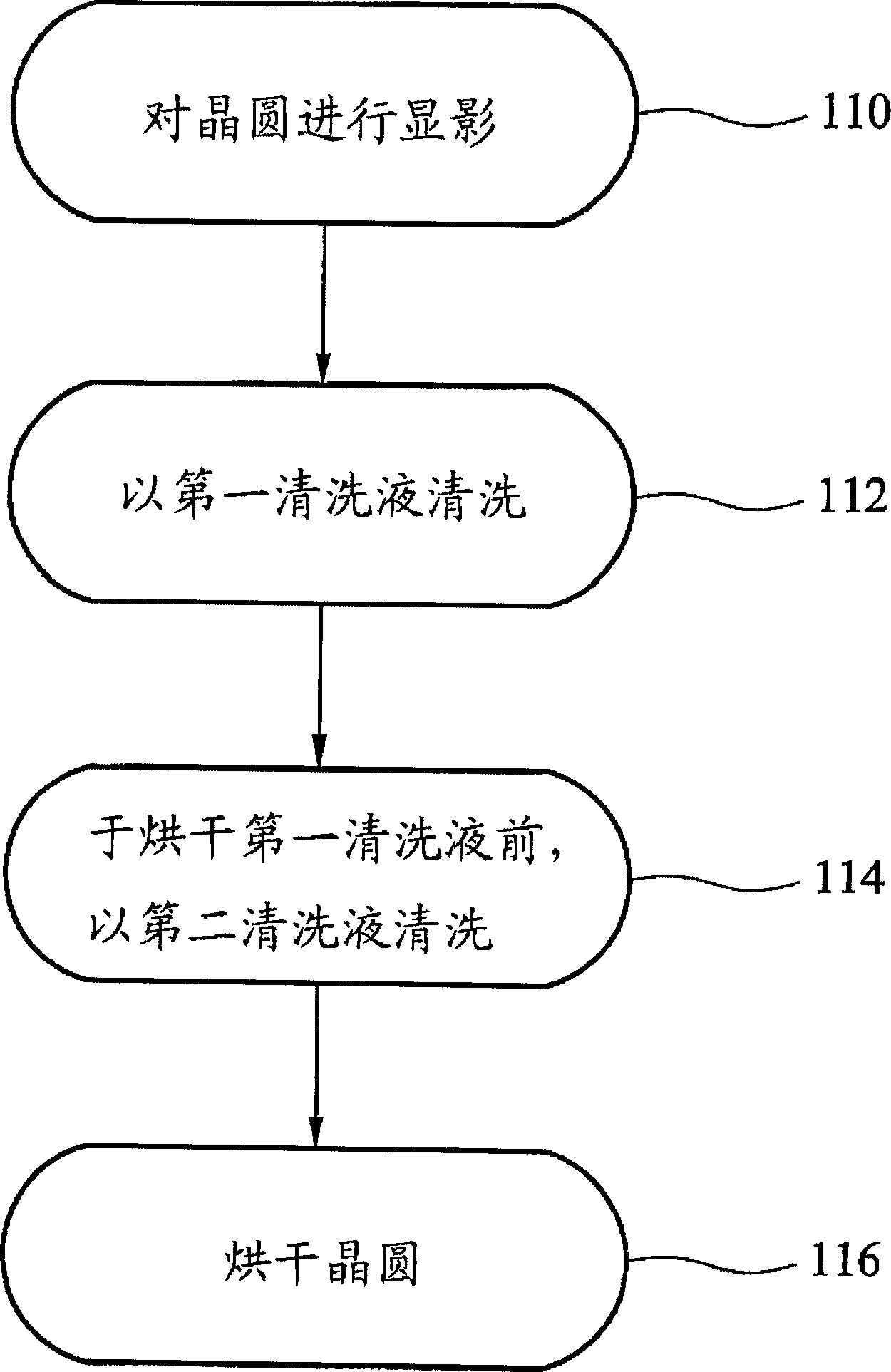

[0037] figure 1 It is a flow chart of making a photoresist mask according to an embodiment of the present invention. The fabrication flow begins with a developing step at step 110 . The developing step includes any known method of supplying a developer, for example, standing, soaking, spraying, stirring, and the like. In this embodiment, an alkaline solvent with a pH value greater than 9 is provided as a developing solution, for example, tetramethyl ammonium hydroxide (TMAH), and its concentration is generally between 0.1% and 2.8%.

...

Embodiment 2

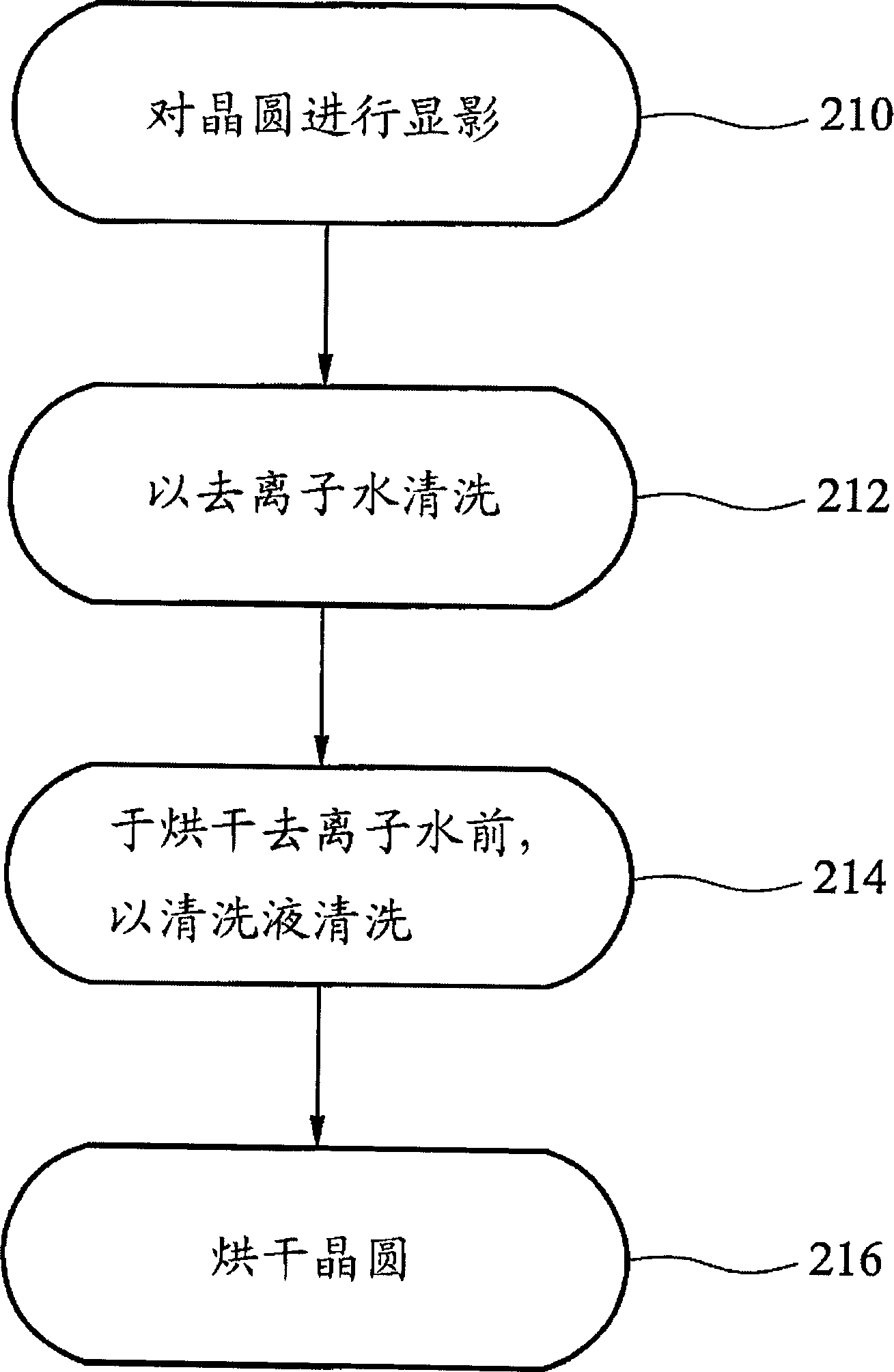

[0045] figure 2 It is a flow chart of making a photoresist mask according to another embodiment of the present invention. The fabrication process begins with a developing step at step 210 . This development step is associated with figure 1 Step 110 is substantially similar.

[0046] Next, perform steps 212 and 214, provide deionized water and cleaning solution to clean the wafer respectively, first clean the wafer with water or deionized water, and then clean it with cleaning solution, and these cleaning steps are all performed before the wafer is dried Finish. As mentioned above, if the wafer is dried before the cleaning step, the photoresist pattern may be dumped. Therefore, between steps 212 and 214, it must be confirmed that there is no wafer drying procedure.

[0047] Cleaning fluids include salt solutions, ionic surfactants, nonionic surfactants, acid solutions, or solutions of dissolved gases. Dissolved gas solutions optionally include dissolved carbon dioxide (C...

Embodiment 3

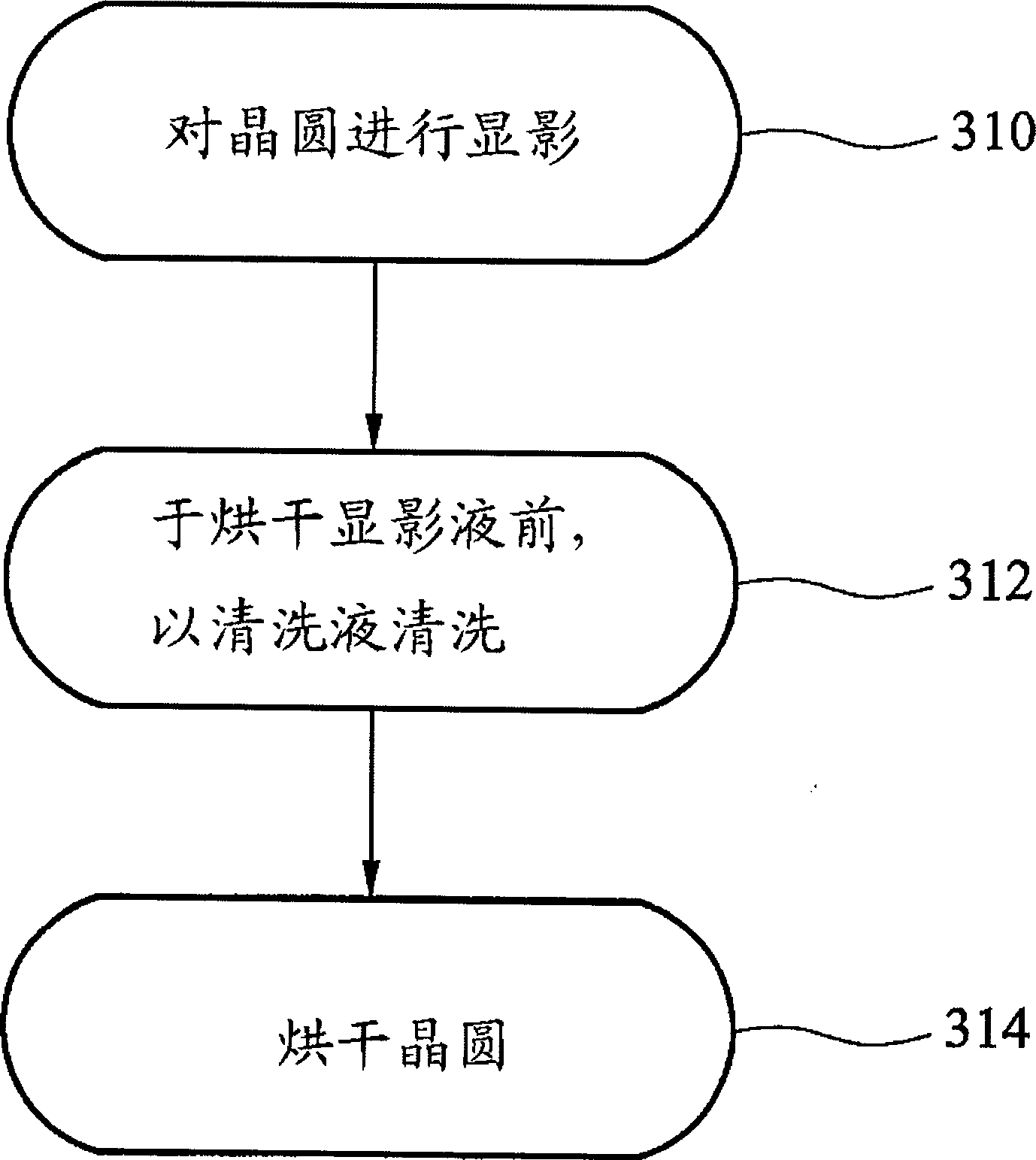

[0051] image 3 It is a flow chart of making a photoresist mask according to another embodiment of the present invention. The fabrication process begins with a development step at step 310 . This development step is associated with figure 1 Step 110 is substantially similar.

[0052] Next, proceed to step 312 , provide a cleaning solution to clean the wafer, and then use the cleaning solution to clean the wafer after the developing step is completed, and the cleaning step must be completed before the wafer is dried. As mentioned above, if the wafer is dried before the cleaning step, the photoresist pattern may be dumped. Therefore, it is necessary to confirm that there is no wafer drying procedure between the developing step and the cleaning step.

[0053] Cleaning fluids include salt solutions, ionic surfactants, nonionic surfactants, acid solutions, or solutions of dissolved gases. Dissolved gas solutions optionally include dissolved carbon dioxide (CO 2 ), sulfur diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com