Low-temperature plasma air purification catalytic reactor and its preparation process

A catalytic reactor, low-temperature plasma technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of activated carbon consumption, uneconomical, secondary pollution, etc., to achieve no secondary pollution, compact structure , easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

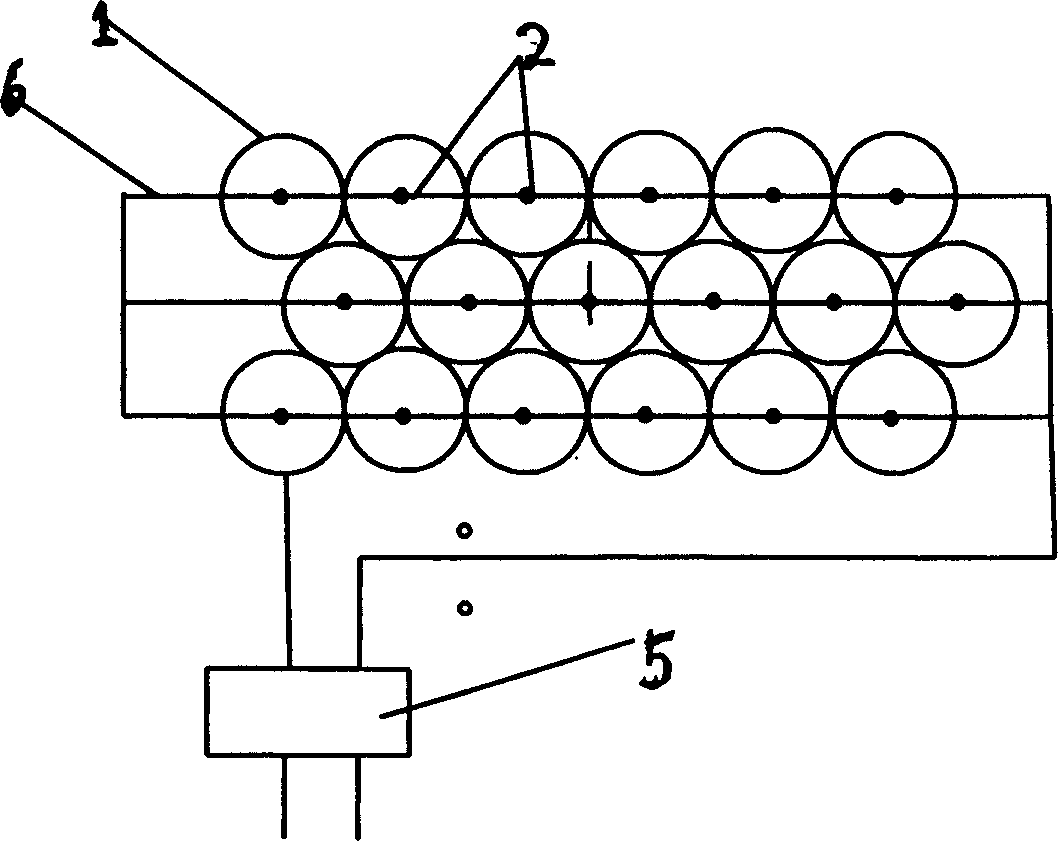

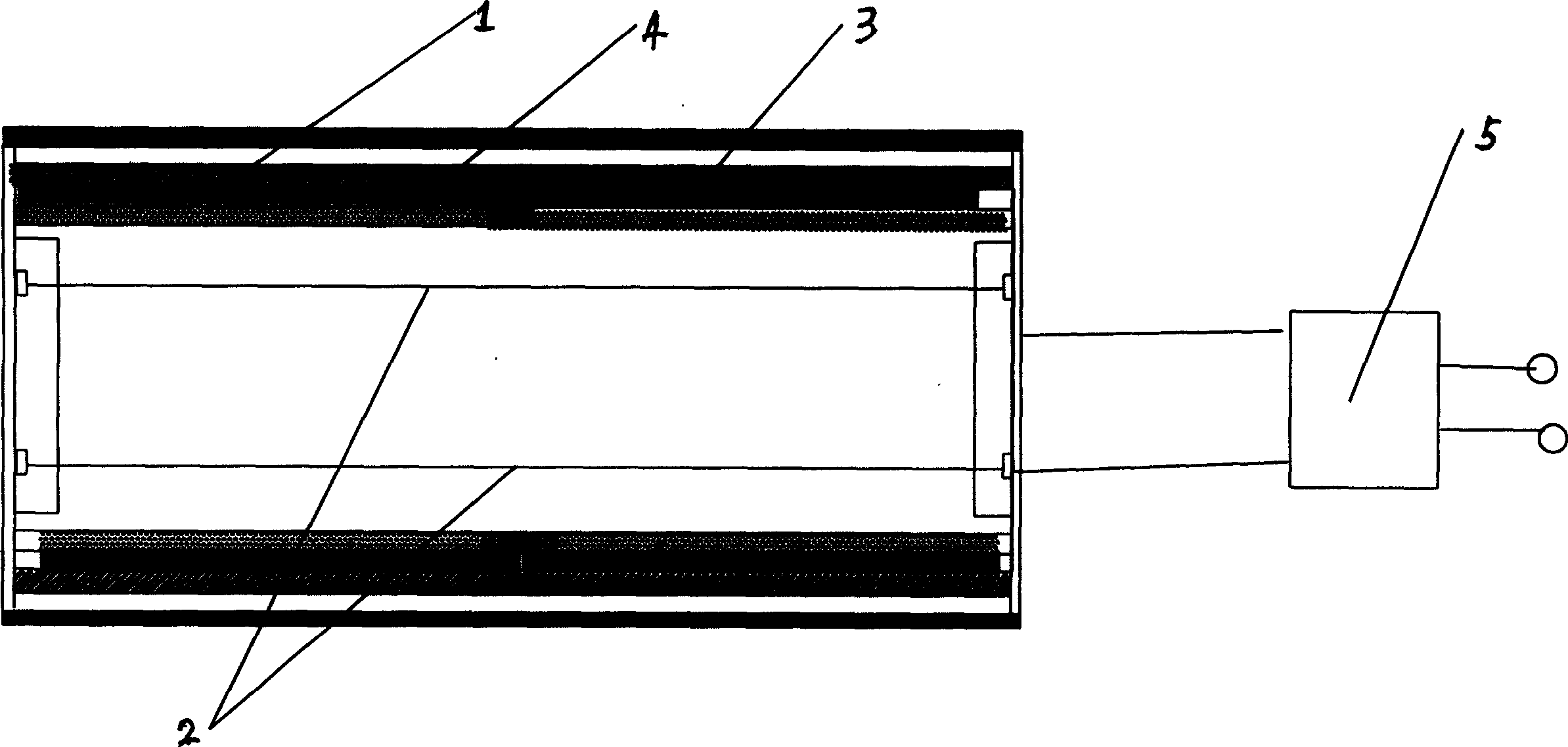

[0050] Take a stainless steel wire mesh with 25% Cr content of 0.3mm wire diameter and 1mm mesh side length, roll the steel mesh into a tube and weld the joints; it is corroded in oxalic acid, washed with water, and anodized to form a wire on the wire. Layer oxide film; take 100 parts by weight of γ-Al 2 O 3 Moisten with water, stir well, add 1 part by weight of concentrated HNO 3 Beating, adding 1 part by weight of binder Al(NO 3 ) 3 ·9H 2 O, then add 10 parts by weight of CeO 2 Powder, 3 parts by weight of La 2 O 3 Powder, 2 parts by weight of ZrO 2 Stir the powder into a slurry, then immerse the oxidized stainless steel mesh into the slurry, take it out after 3 minutes, blow off the excess paint with compressed air, and dry it at a temperature of 100°C for two hours before drying , The tube furnace can be used for automatic and continuous feeding and discharging. The sintering time for entering and leaving the furnace is one hour. The middle section of the furnace is a constant...

Embodiment 2

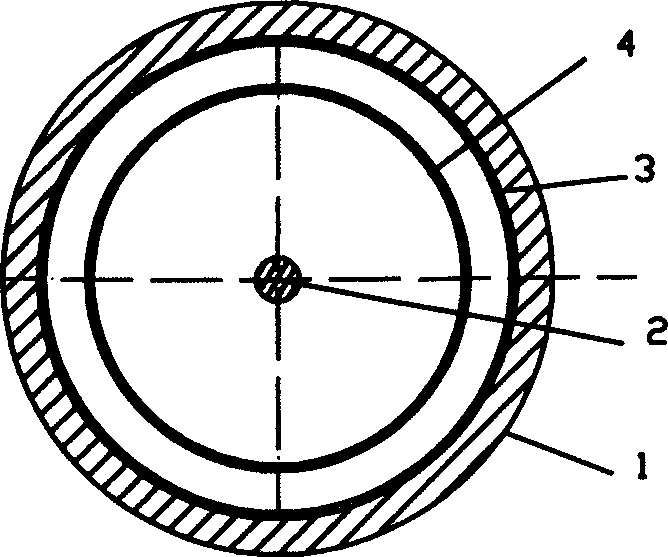

[0056] Refer to figure 1 with figure 2 When using the method described in Example 1 to prepare the product, the inner wall of the cathode tube can be treated to make a layer of Pt as a catalyst attached to the inner wall of the cathode tube. The process includes the following steps:

[0057] (1) To roughen the aluminum plate, you can sand the surface with sandpaper, then degreasing, washing with water, corroding in 2% oxalic acid, then anodizing, cleaning and drying;

[0058] (2) Spray a Pt element salt solution with a concentration of 10 g / L on the aluminum plate obtained in step (1), and reduce it with hydrogen after drying. The reduction reaction temperature is 480° C., and the reduction time is 2 hours.

[0059] It is also possible to paint Pt black directly on the aluminum plate to make the thickness of Pt black 5μm.

[0060] The product number obtained in this example is 2, and its purification effect is shown in Tables 1 to 4.

[0061] Similarly, when the chemical composi...

Embodiment 3

[0063] Take a stainless steel wire mesh containing 25% Cr with a wire diameter of 0.3mm and a mesh side length of 1mm. The stainless steel mesh is made into a plate, corroded in 6% oxalic acid, washed with water, and anodized to form an oxide film on the wire. ; Take 100 parts by weight of γ-Al 2 O 3 Moisten with water, stir well, add 1 part by weight of concentrated HNO 3 Beating, adding 1 part by weight of binder Al(NO 3 ) 3 ·9H 2 O, then add 15 parts by weight of CeO 2 Powder, 5 parts by weight of La 2 O 3 Powder, 2 parts by weight of ZrO 2 Stir the powder into a slurry, then immerse the oxidized stainless steel mesh into the slurry, take it out after 4 minutes, blow off the excess paint with compressed air, and dry it at 100°C for two hours before drying , The tube furnace can be used for continuous feeding and discharging, the middle section of the furnace is a constant temperature section, and the constant temperature is 500 ℃.

[0064] Put the stainless steel wire mesh obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com