High-performance (1-x) BaTi3-xNaNbO3 microwave dielectric film and preparation thereof

A microwave dielectric and high-performance technology, applied in the direction of ceramics, inorganic insulators, etc., to achieve the effect of simple equipment and preparation process, simple device and preparation process, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

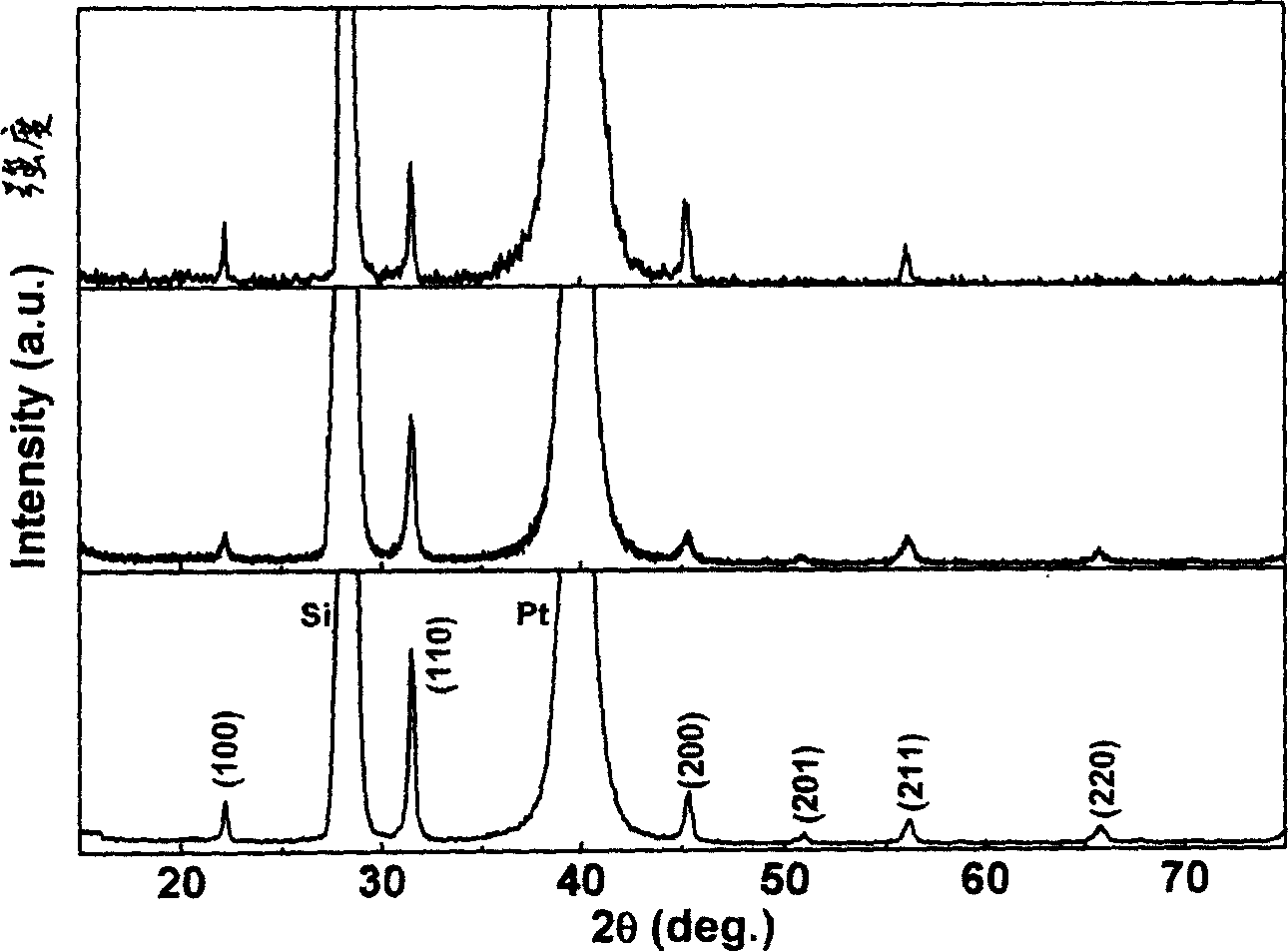

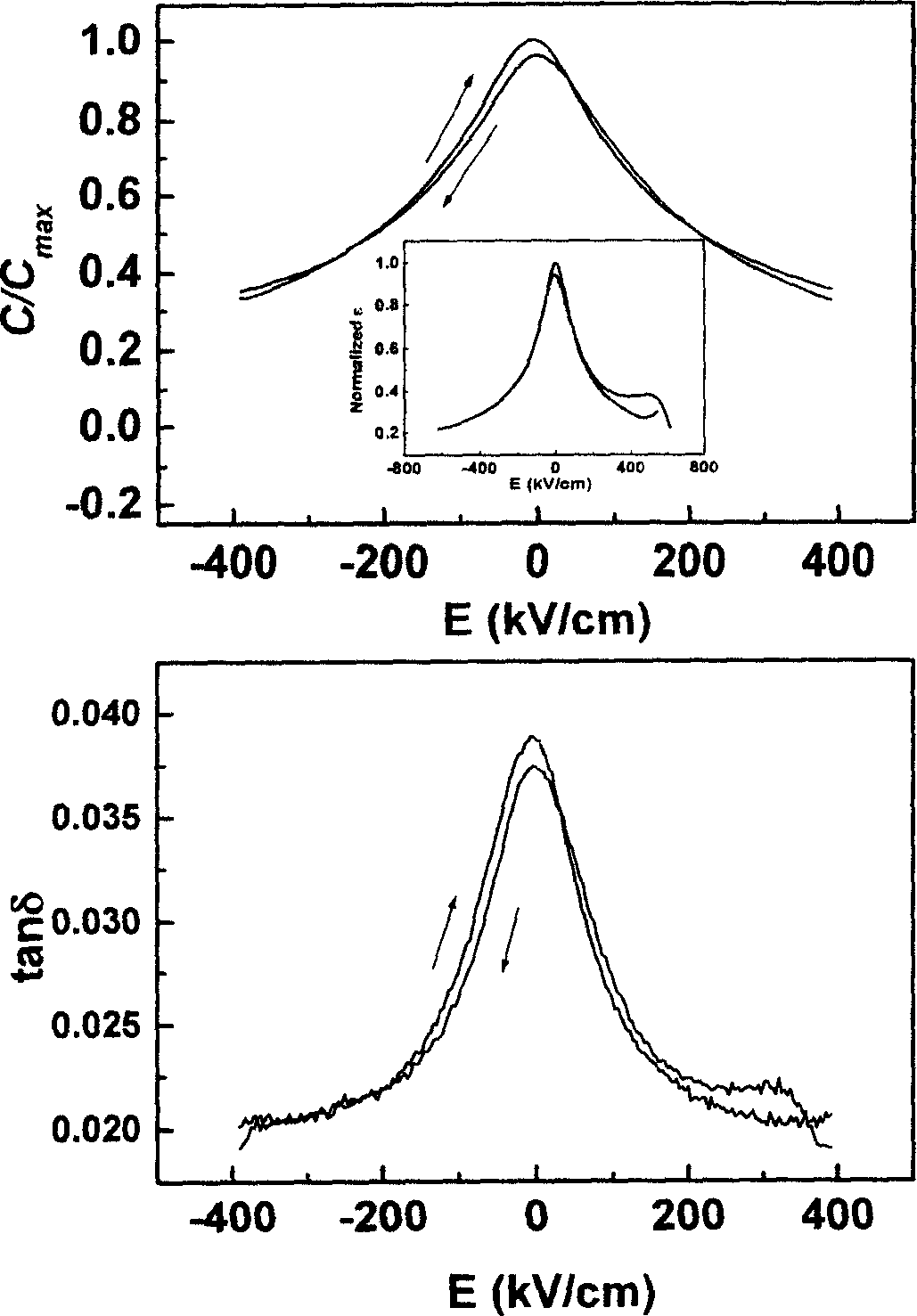

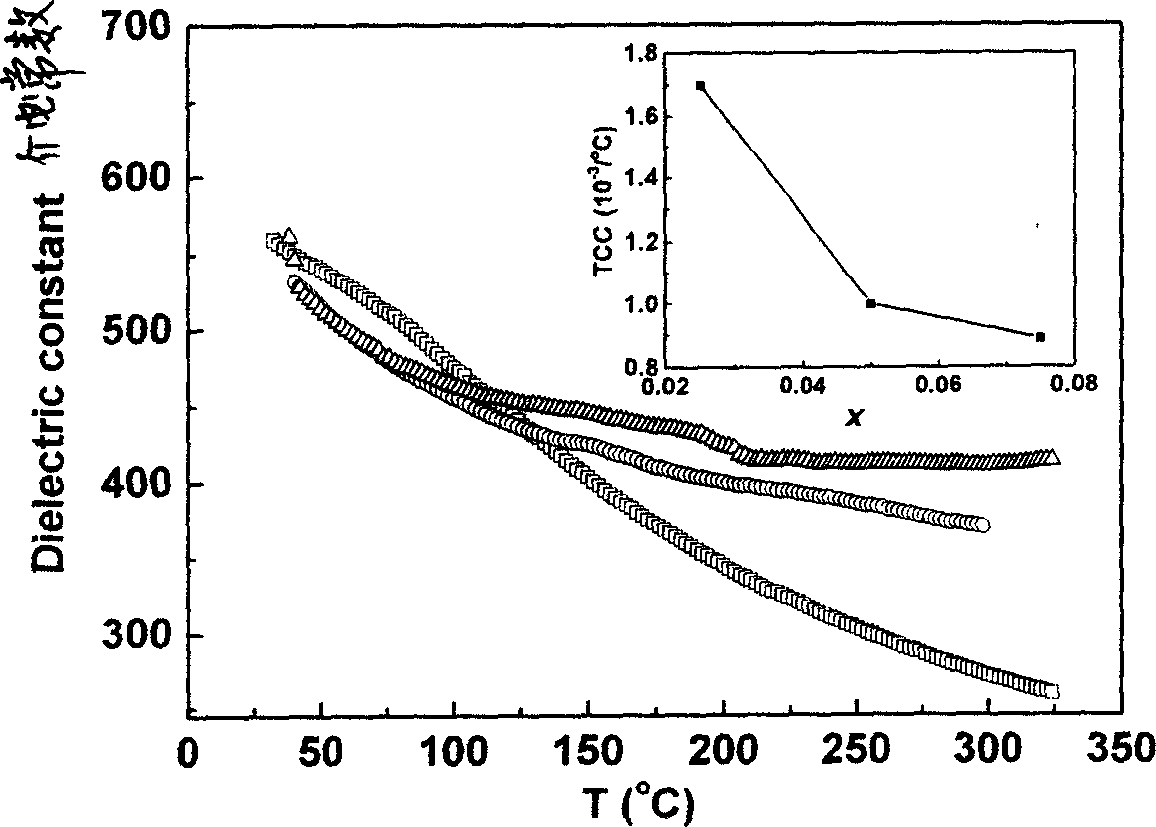

Method used

Image

Examples

Embodiment Construction

[0026] The first step: first determine the value of x, where the range of x is 0.025≤x≤0.075, according to the chemical formula (1-x)BaTiO 3 -xNaNbO 3 , weighing the dried BaCO with a purity greater than 99.0% 3 、TiO 2 、Na 2 CO 3 and Nb 2 o 5 powder, where Na 2 CO 3 Compared with the value required by the stoichiometric ratio, the excess is about 20%. Add alcohol to the mixture of the four powders, and then ball mill (320 rpm, 8 hours) to mix the four powders evenly.

[0027] The second step: after drying the powder obtained in the first step, add an appropriate amount of binder (polyhexenol), and then grind it with a mortar to make it uniform.

[0028] Step 3: Use a pressure of 15 MPa to press an appropriate amount of powder into a thin sheet with a diameter of about 24.0 mm and a thickness of about 3 mm.

[0029] Step 4: Put appropriate amount of corresponding powder into Al 2 o 3Crucible, then put the slice into it, and cover the slice with the corresponding pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com