Supercritical water nuclear reactor utilizing sleeve fuel assembly

A fuel assembly and supercritical water technology, applied in reactors, reactor fuel elements, nuclear engineering, etc., can solve problems such as high operating pressure and inapplicability, improve safety, reduce neutron parasitic absorption, shorten research and development cycle and The effect of R&D spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

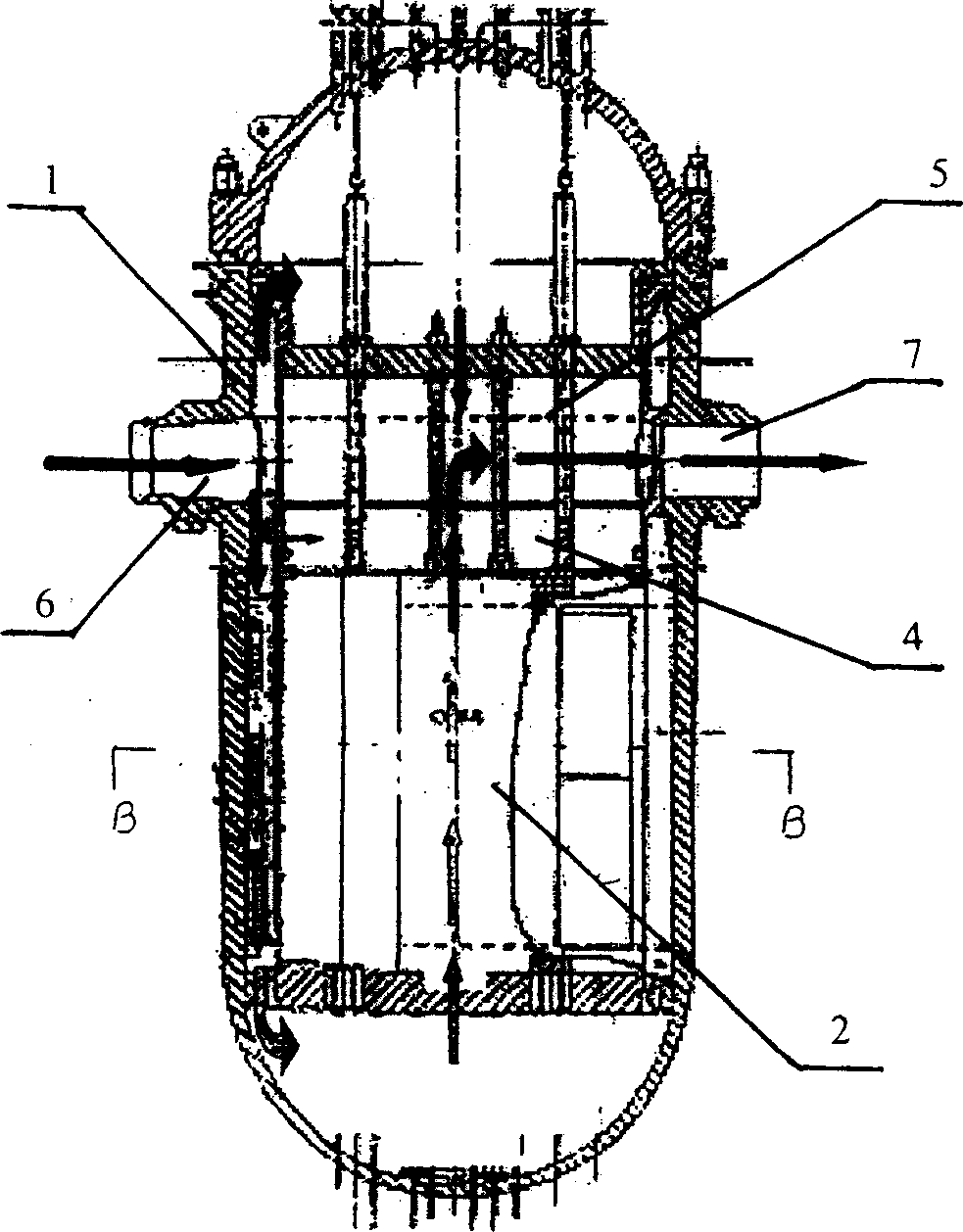

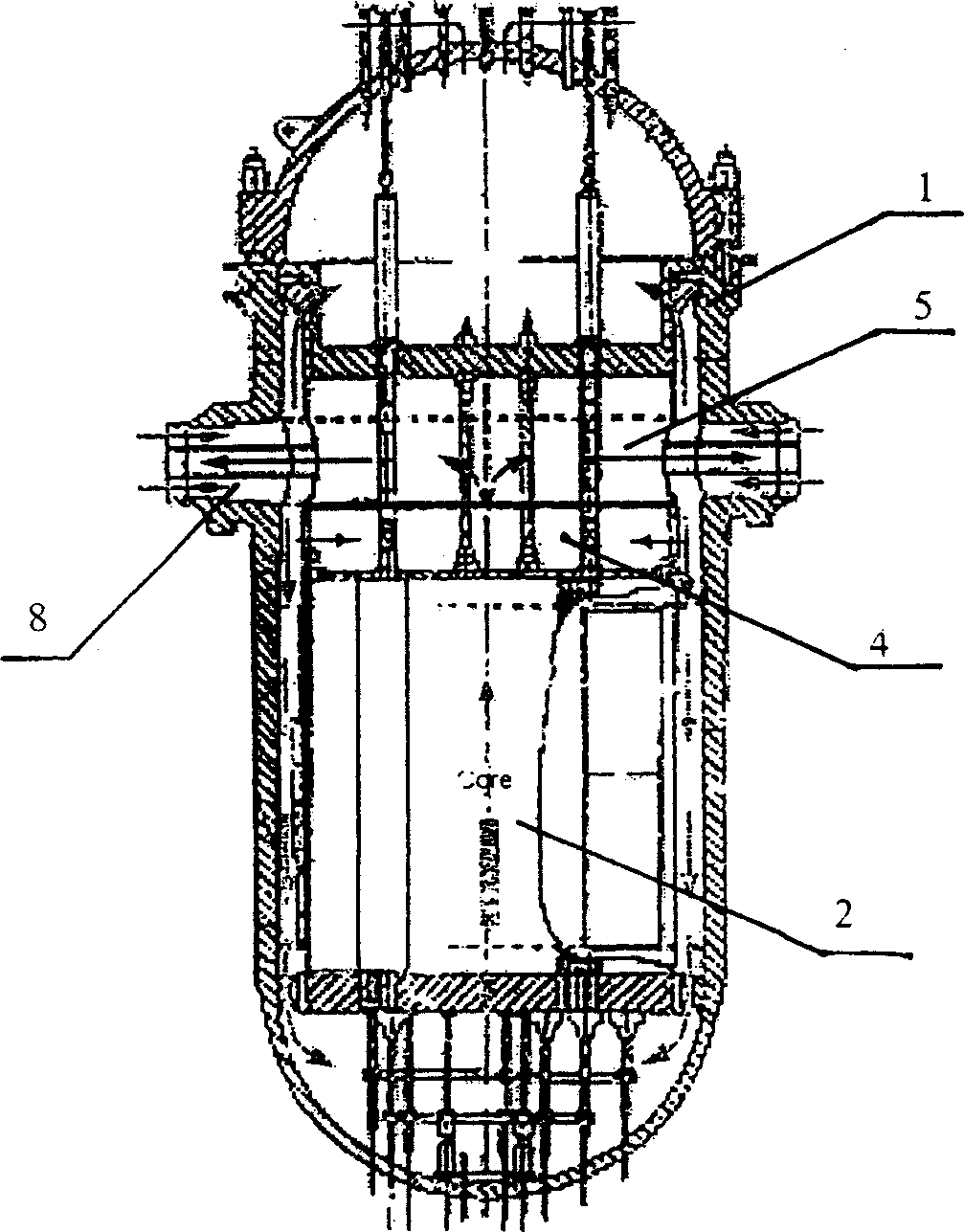

[0028] Such as figure 1 , image 3 As shown, in an embodiment of a supercritical water nuclear reactor with an electric power of 250Mwe (thermal power of 570Mwt) using casing fuel assemblies, the pressure vessel 1 is manufactured by the current PWR mature technology, and its structure is the same as that of the current PWR pressure vessel . Since the inner wall of the pressure vessel only contacts the inlet water (about 280°C), the material can be carbon steel with a stainless steel lining, and the pressure vessel 1 is provided with a core 2 and a control rod bundle mechanism. The area above the core in the pressure vessel is divided into an upper part and a lower part by a thermal insulation partition, the lower part is the inlet water area 4, and the upper part is the outlet water area 5. There are two ways to isolate the inlet water and the outlet water. One is that the pressure shell 1 is respectively provided with a water inlet nozzle 6 communicating with the inlet wate...

Embodiment 2

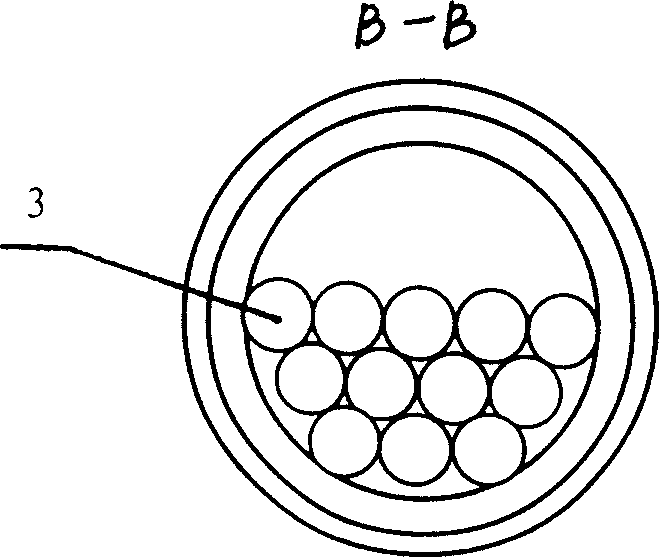

[0031] Another embodiment of the present invention is a supercritical water nuclear reactor adopting a vertical pressure tube casing fuel assembly, including a steel shell and a core and a control rod bundle mechanism placed in the steel shell, and the core is composed of several casings The fuel assembly is composed of the structure of the casing fuel assembly as shown in Figure 8, and each casing fuel assembly includes a coaxial outer casing 13, a middle casing 14, and a center pipe 15, and the gap between the middle casing 14 and the center pipe 15 UO encapsulated by multi-layer SiC-PyC with a millimeter diameter in the annular space 2 The small spherical nuclear fuel element forms an annular fixed bed 16 of coated particles. The outer sleeve 13 is a stainless steel pressure tube that can withstand the design pressure of a supercritical water reactor. The wall thickness is 6.6mm. The outer sleeve 13 is provided with a bundle for Insert the zirconium alloy guide tube of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com