Catalyst for hydrogen oxidation reaction in ethylbenzene dehydrogenation process

A technology for hydrogen oxidation reaction and ethylbenzene dehydrogenation, which is used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrocarbons, etc., and can solve the problem of insufficient oxygen conversion rate or oxygen selectivity. problem, to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The hydrogen oxidation reaction is carried out in a stainless steel reaction tube with an internal diameter of 25 mm, and 30 milliliters of a hydrogen oxidation catalyst is contained inside. The reaction pressure is normal pressure, and the liquid space velocity is 3 hours -1 , The reaction temperature is adjustable from 500 to 650°C. The oil phase after the dehydrogenation reaction in the first reactor of Comparative Example 1, and the added water, oxygen, hydrogen, and nitrogen were used as the hydroxide reactants. The composition of the hydroxide reactants is shown in Table 1.

[0032] raw material

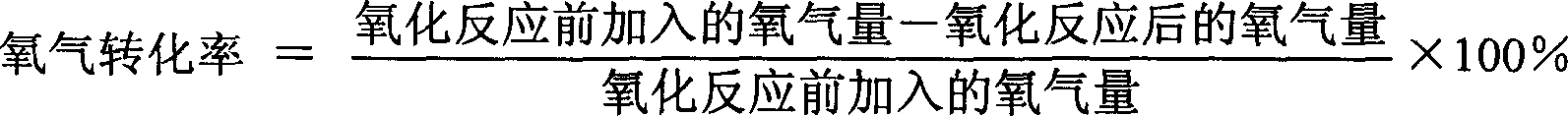

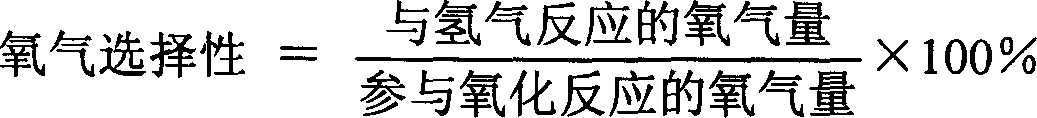

[0033] By measuring the composition of reactants and products, the oxygen conversion and oxygen selectivity of the catalyst in the hydrogen oxidation reaction are calculated.

Embodiment 2

[0035] Take 100 grams of α-alumina particle carrier and impregnate it in 100 milliliters of aqueous solution containing 4.0 grams of chloroplatinic acid, 7.32 grams of zirconyl nitrate, and 8.3 milliliters of hydrochloric acid, dry it at 110°C for 3 hours after taking it out, and treat it with air at 500°C for 2 hours to obtain Catalyst 1.

[0036] Catalyst 1 contained 0.60% by weight Pt and 1.0% by weight zirconium.

[0037] The reaction performance of catalyst 1 was investigated by the method of Example 1, and the reaction performance results at a reaction temperature of 580° C. are shown in Table 2.

Embodiment 3

[0043]Take 100 grams of α-alumina particle carrier and impregnate it in 100 milliliters of aqueous solution containing 24.8 grams of titanium tetrachloride, take it out and dry it at 120°C for 2 hours; then impregnate it in 8.0 grams of chloroplatinic acid, 16 grams of 18.3 grams of zirconyl nitrate and 8.3 milliliters of hydrochloric acid in 100 milliliters of aqueous solution were taken out, dried at 120°C, and treated with air at 450°C for 2 hours to obtain catalyst 3.

[0044] Catalyst 3 contained 1.20% by weight of Pt, 4.0% by weight of Sn, 2.5% by weight of titanium and 2.5% by weight of zirconium.

[0045] The reaction performance of catalyst 3 was investigated by the method of Example 1, and the reaction performance results at a reaction temperature of 580° C. are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com