Olefin polymerization inhibitor and its prepn process

A polymerization inhibitor, olefin technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve the problems of tray and reboiler scaling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

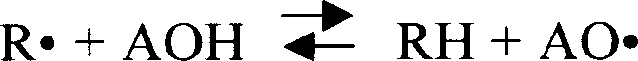

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Preparation of Nitroxide Radicals

[0032] Heat the mixture of 2,2,6,6-tetramethyl-4-alkoxypiperidine: disodium ethylenediaminetetraacetic acid: sodium carbonate: water = 100: 0.35: 0.2: 200 to 50°C, Adding the concentration of 3 times the weight of the mixed solution is 50% hydrogen peroxide, and it is incubated for 5 hours to generate 4-alkoxy-2,2,6,6-tetramethylpiperidine nitroxide free radical; then

[0033] b. add ethylenediamine;

[0034] c. Add dimethylformamide and water, and mix to obtain the product.

[0035] d. In parts by weight, take dimethylformamide 5, diamine or alkylamine or alkanolamine compound 15, 4-alkoxy-2,2,6,6-tetramethylpiperidine nitrogen oxide Free radical 5 and water 50 are mixed evenly to obtain the product.

Embodiment 2

[0037] a. Preparation of Nitroxide Radicals

[0038] Heat the mixture of 2,2,6,6-tetramethyl-4-alkoxypiperidine: disodium ethylenediaminetetraacetic acid: sodium carbonate: water = 100:0.5:0.3:100 to 95°C, Then add 30% hydrogen peroxide of 8 times the weight of the mixed solution, and keep warm for 3 hours to generate 4-alkoxy-2,2,6,6-tetramethylpiperidine nitroxide free radical; then

[0039] b. add propylene diamine;

[0040] c. Add dimethylformamide and water, and mix to obtain the product.

[0041] d. In parts by weight, take dimethylformamide 30, diamine or alkylamine or alkanolamine compound 10, 4-alkoxy-2,2,6,6, tetramethylpiperidine nitrogen oxide Free radical 10 and water 70 are mixed evenly to obtain the product.

Embodiment 3

[0043] a. Preparation of Nitroxide Radicals

[0044] Heat the mixture of 2,2,6,6-tetramethyl-4-alkoxypiperidine: disodium ethylenediaminetetraacetic acid: sodium carbonate: water = 100:1:0.5:350 to 70°C, Then add 40% hydrogen peroxide of 0.5 times the weight of the mixed solution, and keep warm for 10 hours to generate 4-alkoxy-2,2,6,6-tetramethylpiperidine nitroxide free radical; then

[0045] b. add butanediamine;

[0046] c. Add dimethylformamide and water, and mix to obtain the product.

[0047] d. In parts by weight, take dimethylformamide 10, diamine or alkylamine or alkanolamine compound 3,4-alkoxy-2,2,6,6-tetramethylpiperidine nitrogen oxide Free radicals 1, hydration 60 evenly to get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com