Vertical liquid crystal orientating agent and vertical liquid crystal display element

A technology for liquid crystal display elements and liquid crystal orientation, which is applied to liquid crystal materials, static indicators, instruments, etc., and can solve the problems of reducing the number of liquid crystal display elements and the small size of the parent substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

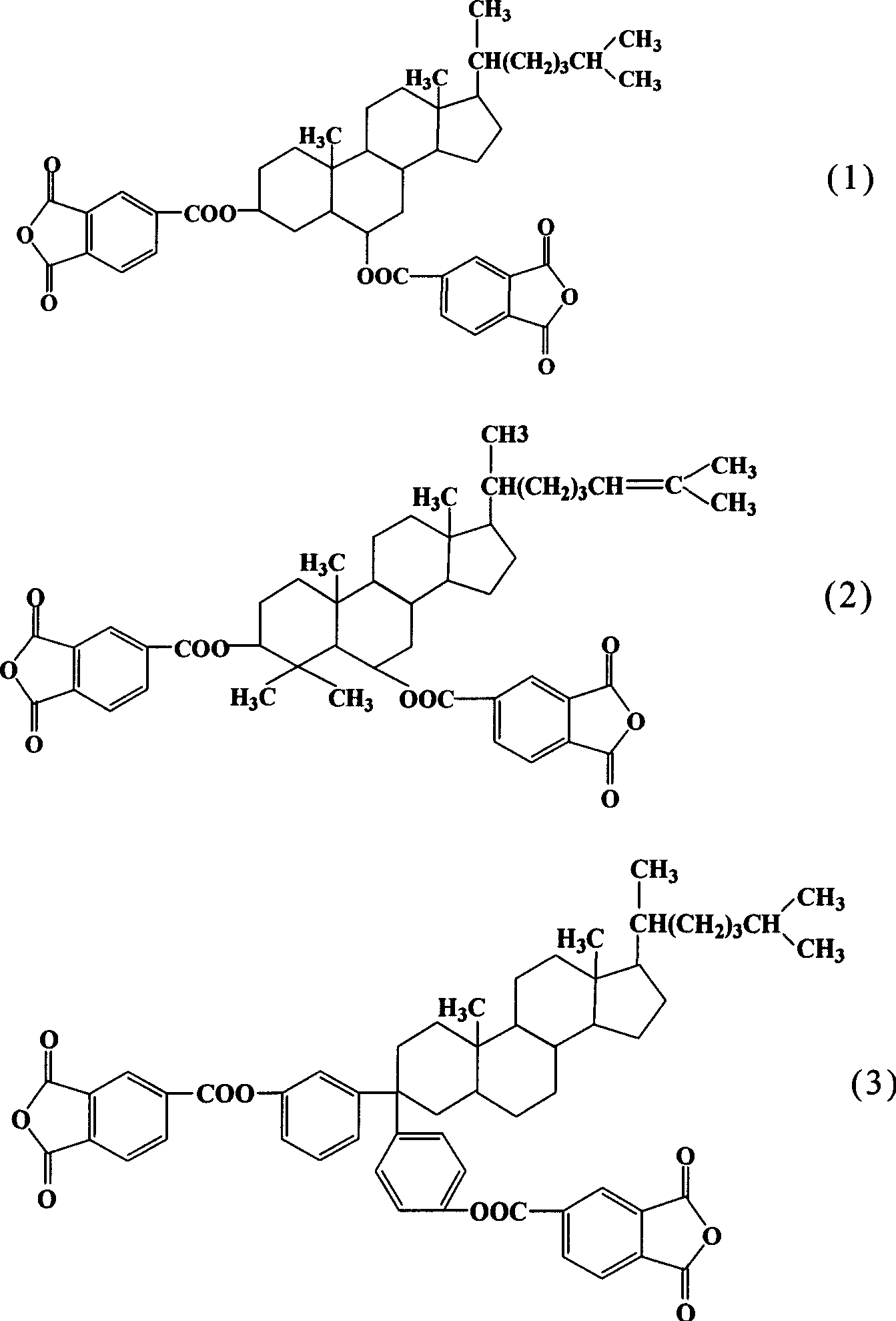

Synthetic example 1

[0115] With 2,3,5-tricarboxycyclopentyl acetic acid dianhydride 224.17g (1.0 mole) as tetracarboxylic dianhydride, p-phenylenediamine 68.13g (0.63 mole) as diamine compound, above-mentioned formula (16 ) represented by 193.44 g (0.37 moles) of the diamine compound was dissolved in 4500 g of N-methyl-2-pyrrolidone and reacted at 60° C. for 6 hours. Next, the reaction solution was injected into a large excess of methanol to precipitate the reaction product, and then washed with methanol and dried at 40° C. under reduced pressure for 15 hours to obtain 520 g of polyamic acid with a logarithmic viscosity of 0.57 dl / g . Dissolve 30 g of the obtained polyamic acid in 570 g of N-methyl-2-pyrrolidone, add 5.7 g of pyridine and 7.4 g of acetic anhydride, dehydrate and close the ring at 110 ° C for 4 hours, carry out the same precipitation, washing, and decompression as above to obtain 19.0 g of a polyimide having a logarithmic viscosity of 0.50 dl / g (which is referred to as "polyimide...

Synthetic example 2

[0117] In Synthesis Example 1, except that 77.86 g (0.72 mol) of p-phenylenediamine and 146.38 g (0.28 mol) of the diamine compound represented by the above-mentioned formula (16) were used as the diamine compound, the same procedure as in Synthesis Example 1 was used to obtain 390 g of polyamic acid with a logarithmic viscosity of 0.45 dl / g. Except for using 30 g of the obtained polyamic acid, imidization was carried out in the same manner as in Synthesis Example 1 to obtain 18.9 g of polyimide (called "polyimide (PI- 2)").

Synthetic example 3

[0119]In Synthesis Example 2, except that 95.16 g (0.88 mol) of p-phenylenediamine and 62.74 g (0.12 mol) of the diamine compound represented by the above-mentioned formula (16) were used as the diamine compound, the same operation as in Synthesis Example 2 was performed to obtain 450 g of polyamic acid with a logarithmic viscosity of 0.38 dl / g. Then, except that 4.8 g of pyridine and 6.1 g of acetic anhydride were used, the same operation was performed as in Synthesis Example 2 to obtain 20.3 g of polyimide (which is called "polyimide (PI)" with a logarithmic viscosity of 0.40 dl / g. -3)").

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com