Colored photosensistive resin composition, coating film of colored photosensitive resin composition, photosensitive resin transfer material

A technology of photosensitive resin and photosensitive resin layer, which is applied in the field of color filters, can solve the problem of not obtaining sufficient color purity color filters, and achieve the effect of high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

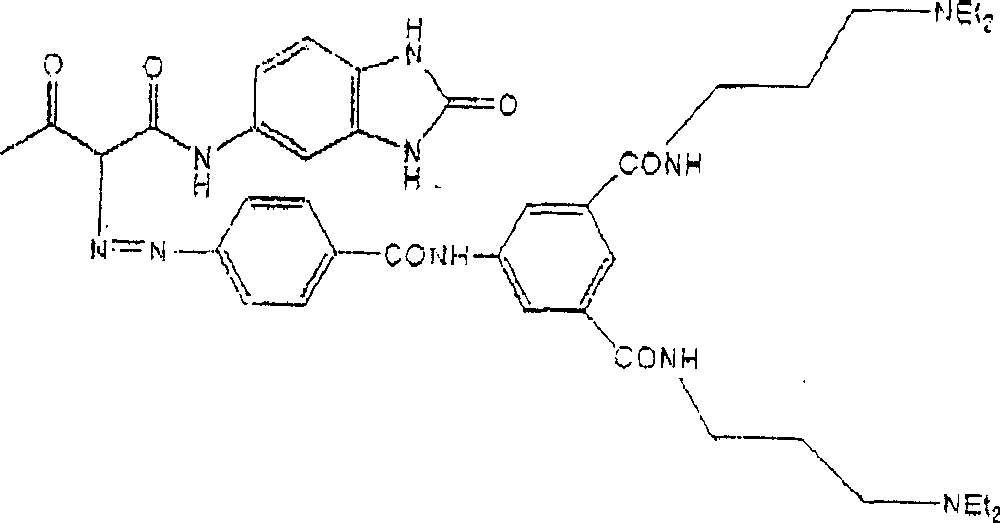

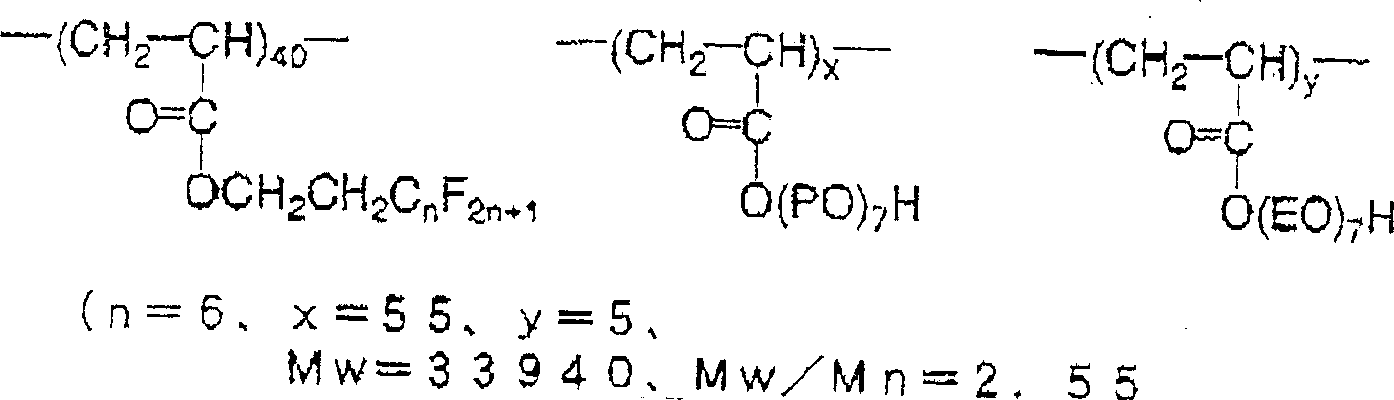

Method used

Image

Examples

Embodiment 1

[0129] [Manufacturing of color filters (manufacturing by coating using a slit nozzle)]

[0130] —Formation of black (K) image—

[0131] Wash the alkali-free glass substrate with a UV washing device, then use a detergent to scrub, and then use ultrapure water to perform ultrasonic cleaning. This substrate was heat-treated at 120° C. for 3 minutes to stabilize the surface state.

[0132] The substrate was cooled and the temperature was adjusted to 23° C., and then the components described in the following Table 2 were coated with a glass substrate coater (manufactured by FAS Japan Co., Ltd., trade name: MH-1600) with a slit nozzle. Composition of the following colored photosensitive resin composition K1. Then use VCD (vacuum drying device; Tokyo Ohka Co., Ltd.) to dry for 30 seconds to volatilize part of the solvent and make the coating layer have no fluidity. The required coating solution was prebaked at 120° C. for 3 minutes to obtain a photosensitive resin layer K1 with a ...

Embodiment 2-10 and comparative example 1-3

[0201] Except that the compositions of the colored photosensitive resin compositions R1, G1, and B1 used in Example 1 were changed to the colored photosensitive resin compositions R2-13, G2-13, and B2-13 described in Table 3-5 above. Except for the composition of , the target color filter was obtained in the same manner as in Example 1.

[0202] The film thicknesses of the photosensitive resin layers of R, G, and B, and the coating amounts of the respective pigments are shown in Tables 6-8.

[0203] [evaluate]

[0204] —Measurement of Chromaticity—

[0205] The chromaticity of the color filter obtained above was measured with a pinhole diameter of 5 μm using a microspectrophotometer (manufactured by Olympus Optical Co., Ltd.; OSP100), and calculated as a result of a field of view of F10 light source of 2 degrees. The results (xyY values, and the difference (ΔE) from the target chromaticity) are shown in Tables 6-8.

[0206] -Uneven coating-

[0207]A sodium lamp was irradi...

Embodiment 11

[0222] [Production of color filters (production by lamination of photosensitive resin transfer material)]

[0223] —Production of photosensitive resin transfer materials—

[0224] On a polyethylene terephthalate film temporary support having a thickness of 75 μm, a coating liquid for a thermoplastic resin layer composed of the following formulation H1 was applied using a slit nozzle, and dried. Next, a coating liquid for an intermediate layer consisting of the following formulation P1 was applied and dried. The above-mentioned colored photosensitive resin composition K1 is then applied and dried, so that a thermoplastic resin layer with a dry film thickness of 14.6 μm, an intermediate layer with a dry film thickness of 1.6 μm, and a dry film thickness of 2.4μm photosensitive resin layer, and crimp a protective film (polypropylene film with a thickness of 12μm).

[0225] As mentioned above, a photosensitive resin transfer material in which the temporary support, thermoplastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com