Laser color display device possessing three primary colors of red, green and blue

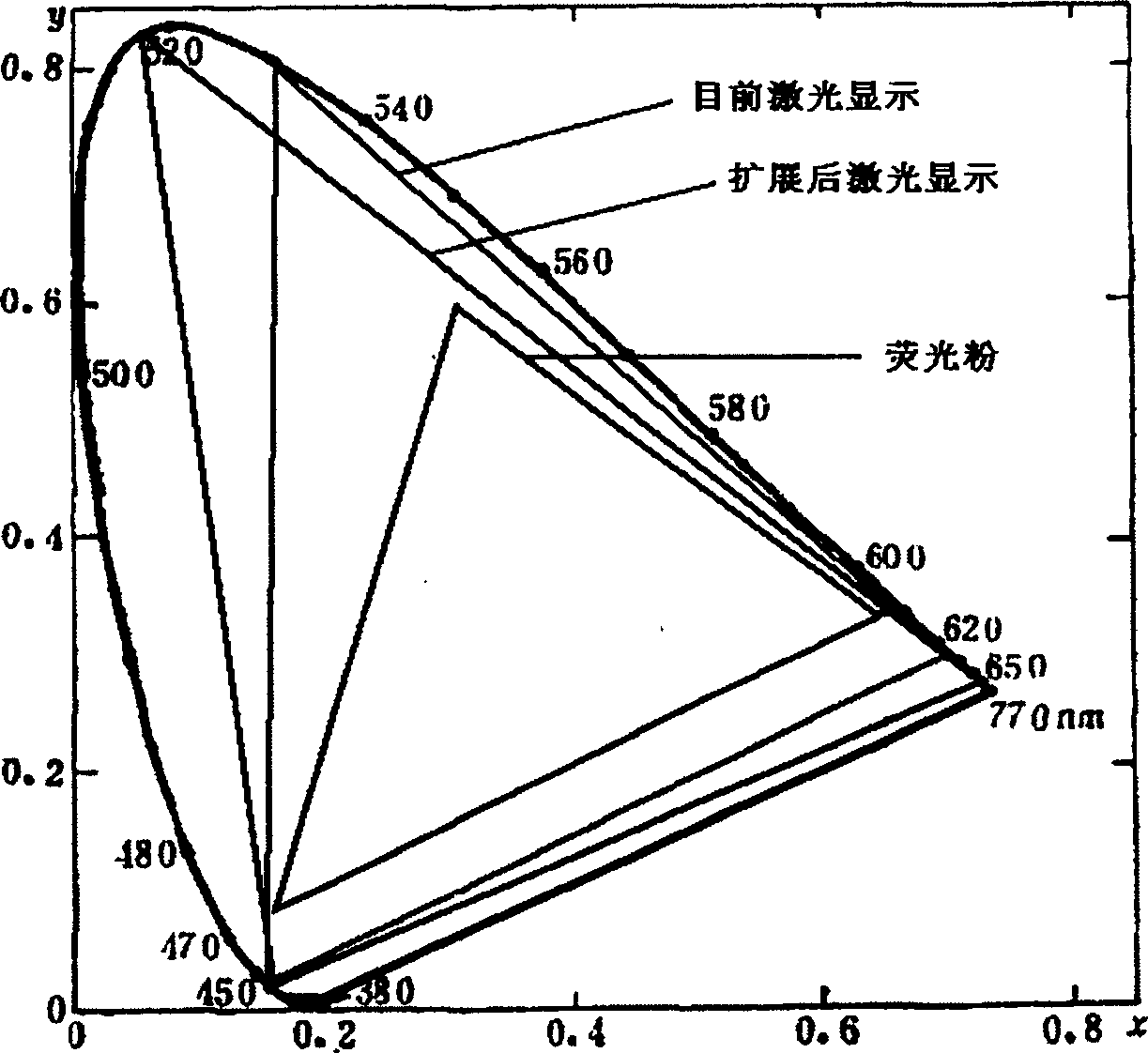

A color display and tri-primary color technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem of not bright enough colors, and achieve the effect of bright colors, rich colors, and extended color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

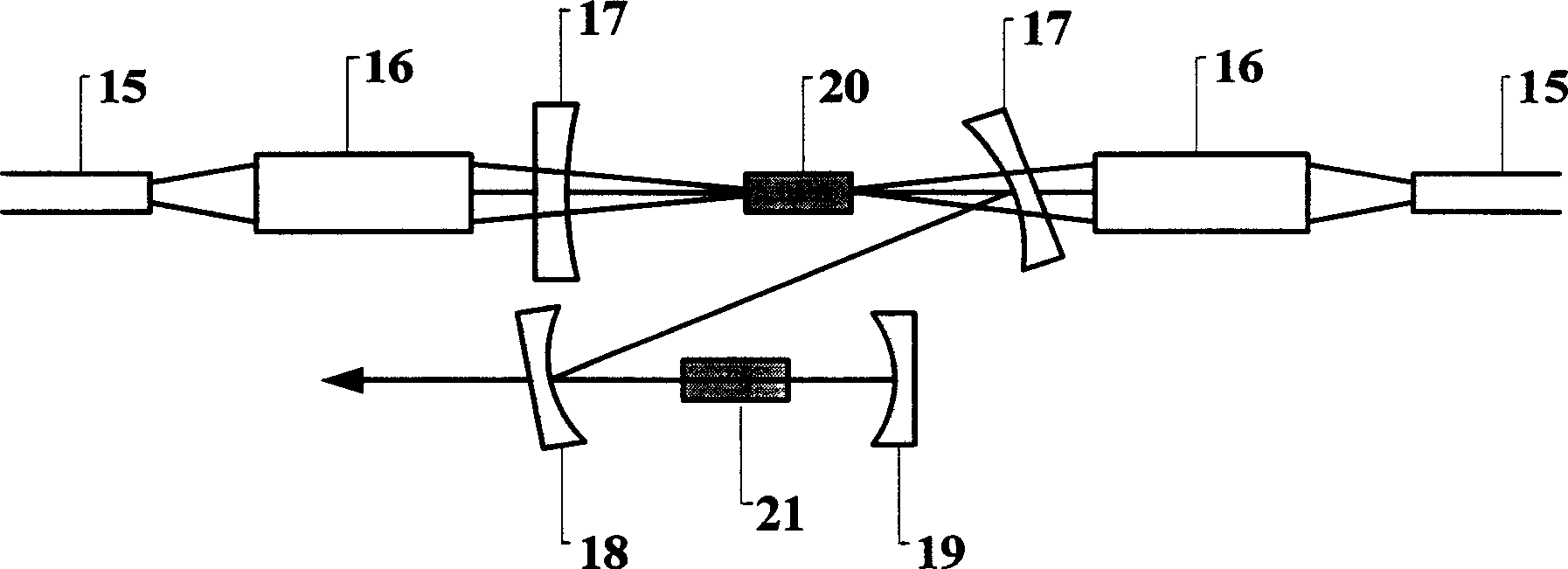

[0044] according to image 3 The optical path to make a 671 / 660nm red laser

[0045] The laser crystal 20 uses Nd:YV04 or Nd:YAG crystal, on which an optical film is coated, the coating parameters are HT@808nm&1342nm or HT@808nm&1319nm, the pump light source 15 adopts an 808nm semiconductor laser LD, and a coupling system 16 is set on the optical path in front of the pump light source 15 1. A resonant cavity made of a pair of resonant cavity mirrors 17, 18 and 19 resonant cavity mirrors. The laser crystal 20 is placed in the middle of the pair of resonant cavity mirrors 17. A non- A linear optical crystal 21 ; a coupling system 16 and a pump light source 15 are placed on the output optical path of the cavity mirror 17 .

[0046] After the pumping light is pumped by the coupling system 16, the fluorescence of 1342nm or 1319nm is generated. By adjusting the cavity mirrors 17, 18, 19, the fluorescence of 1342nm or 1319nm is oscillated to generate laser light. The nonlinear optical...

Embodiment 2

[0056] according to Figure 4 Make a side-pumped 660nm red laser with the optical path

[0057] The laser crystal 20 uses Nd:YAG rods, and the two transparent surfaces are coated with 1319nm anti-reflection film; the pump light 15 adopts a multi-dimensional 808nm semiconductor laser array and places it around the laser crystal 20 according to a certain shape and position. The components formed in this way are called One laser head, only one laser head can be used in the optical path, and multiple laser heads can also be used in series. When two laser heads are used in series, a 90-degree optical rotation plate 23 is inserted between them to compensate for thermally induced birefringence. A composite resonant cavity composed of a pair of resonant cavity mirrors 17, 18 and 19 is arranged sequentially on the optical paths on both sides of the head, and a nonlinear optical crystal 21 is placed between the resonant cavity mirror 18 and the resonant cavity mirror 19; The two laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com