Rise full liquid state fermentation brewing technology

A technology of liquid fermentation and rice, applied in the field of microbial fermentation, can solve the problems of low raw material utilization rate, high production cost, high labor intensity, etc., and achieve the effect of increasing starch utilization rate, increasing labor productivity, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

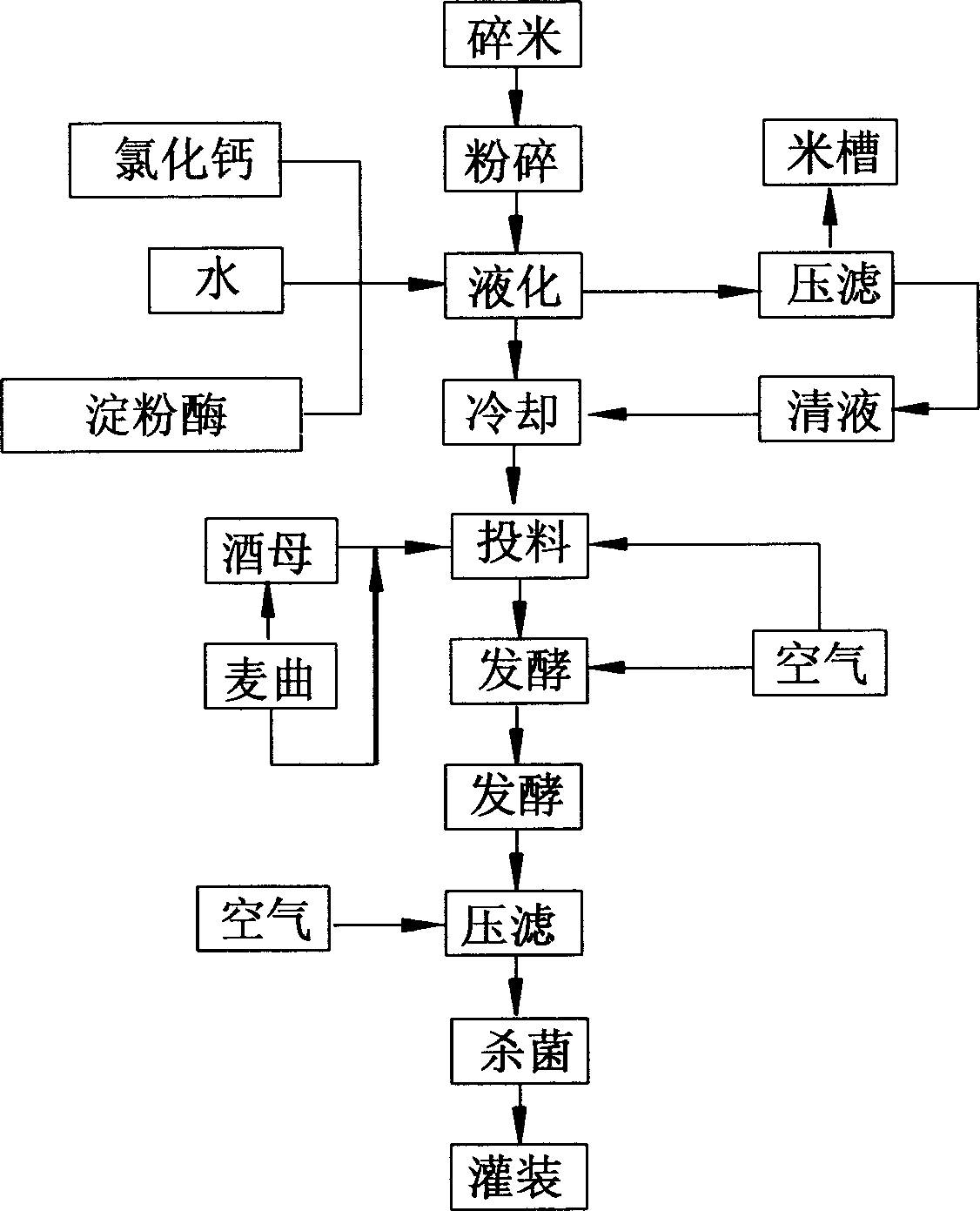

[0019] Ingredients: Grind 4000Kg of indica broken rice into 40-mesh rice flour, take 8000Kg of water, 2600g of calcium chloride, and 3000mL of high-temperature-resistant α-amylase (diluted with 15 times the amount of water).

[0020] like figure 1 As shown in , add rice flour to 8000Kg water and mix, add calcium chloride 2600g, adjust pH to 6.0 with edible phosphoric acid, stir and heat to 50°C, keep warm for 10 minutes, then heat to 65°C and add 2000ml high temperature resistant α-amylase (diluted with 15 times the amount of water), continue to heat to 90°C and add 1000ml of high-temperature-resistant α-amylase (diluted with 15 times the amount of water), mix well, keep warm at 90°C-92°C, liquefy for about 50 minutes, and add iodine The test reaction is complete (the test paper is reddish brown), if the iodine test reaction is not complete, the time can be extended appropriately.

[0021] The liquefied liquid is heated and boiled to inactivate α-amylase, and then transported...

Embodiment 2

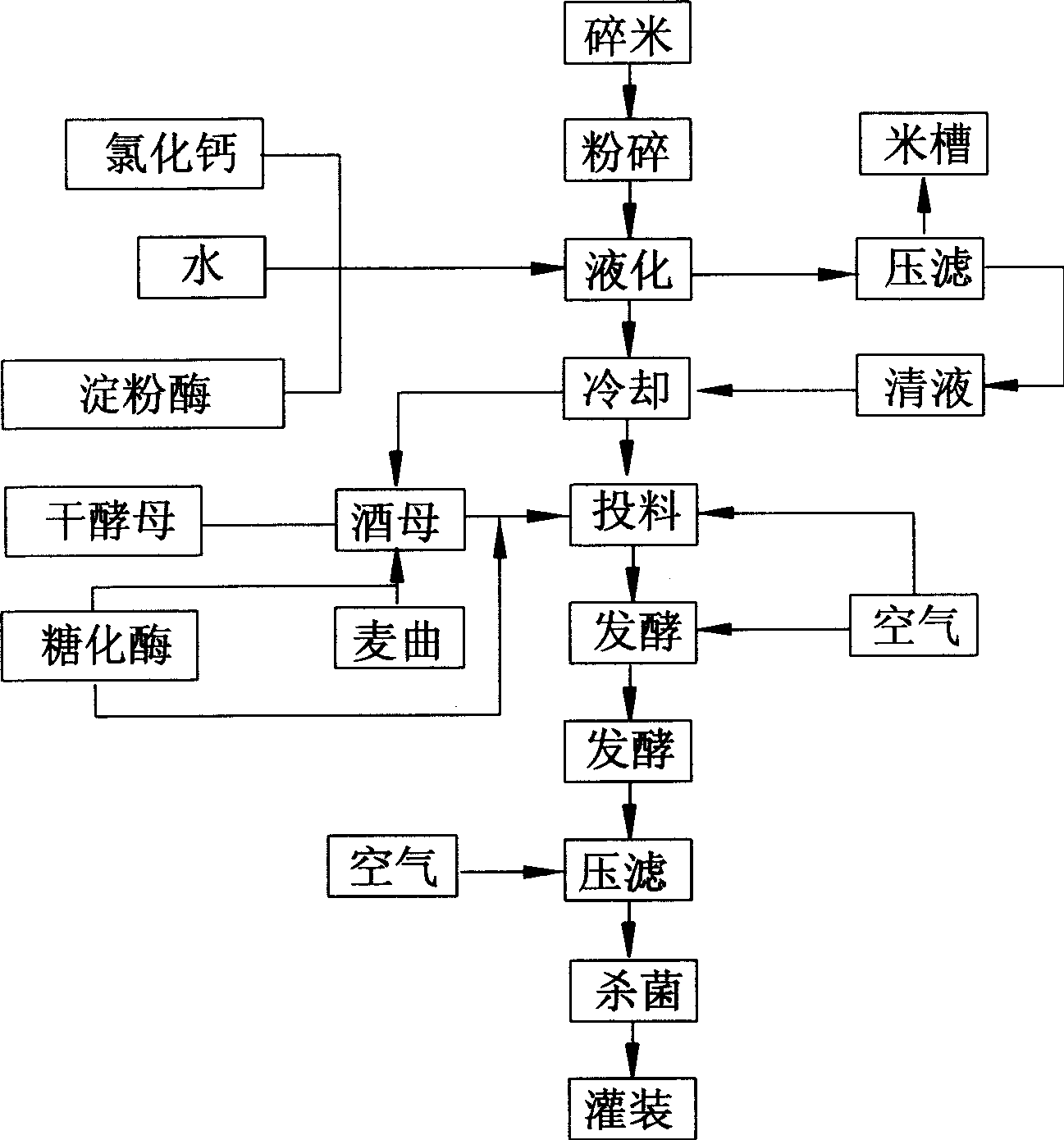

[0024] Ingredients: Grind 4000Kg of indica broken rice into 60-mesh rice flour, take 8400Kg of water, 2600g of calcium chloride, and 3000mL of high-temperature-resistant α-amylase (dilute with 15 times the amount of water).

[0025] like figure 2 As shown in , add rice flour to 8400Kg water and mix, add calcium chloride 2600g, adjust pH to 5.9 with edible phosphoric acid, stir and heat to 50°C, keep warm for 10 minutes, then heat to 65°C and add 2000ml high temperature resistant α-amylase (diluted with 15 times the amount of water), continue to heat to 90°C and add 1000ml of high-temperature-resistant α-amylase (diluted with 15 times the amount of water), mix well, keep warm at 90°C-92°C, liquefy for about 50 minutes, and add iodine The test reaction is complete (the test paper is reddish brown), if the iodine test reaction is not complete, the time can be extended appropriately.

[0026] The liquefied liquid is heated and boiled to inactivate α-amylase, and then 50% of the ...

Embodiment 3

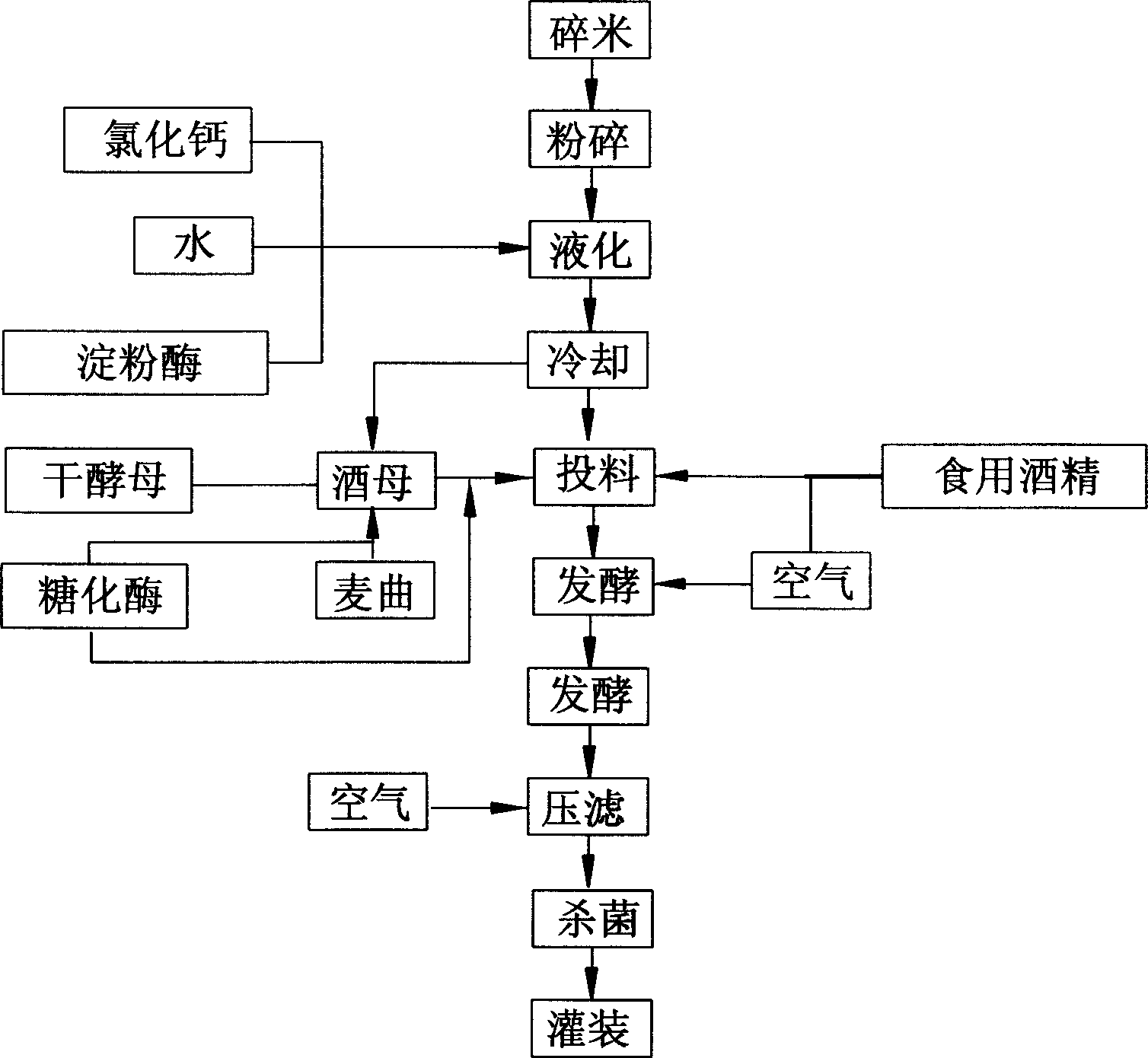

[0029] Ingredients: crush 4000Kg of indica rice into 50 mesh rice flour, take 7600Kg of water, 2600g of calcium chloride, and 3000ml of high-temperature-resistant α-amylase (diluted with 15 times the amount of water).

[0030] like image 3 As shown in , add rice flour to 7600Kg water and mix, add calcium chloride 2600g, adjust pH to 6.0 with edible phosphoric acid, stir and heat to 50°C, keep warm for 10 minutes, then heat to 65°C and add 2000ml high temperature resistant α-amylase (diluted with 15 times the amount of water), continue to heat to 90°C and add 1000ml of high-temperature-resistant α-amylase (diluted with 15 times the amount of water), mix well, keep warm at 90°C-92°C, liquefy for about 50 minutes, and add iodine The test reaction is complete (the test paper is reddish brown), if the iodine test reaction is not complete, the time can be extended appropriately.

[0031] The liquefied liquid is heated and boiled to inactivate α-amylase, and then transported to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com