Method and system for desulfurization in wet-process of limestone-gypsum, and resource process of desulfurized gypsum

A technology for wet desulfurization and desulfurization gypsum, which is applied in the field of limestone-gypsum wet desulfurization and desulfurization gypsum resource treatment and systems, can solve the problems of desulfurization by-product treatment, environmental pressure, remote pollution and other problems, and reduce the cost of re-dehydration , the effect of reducing pollution pressure and project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

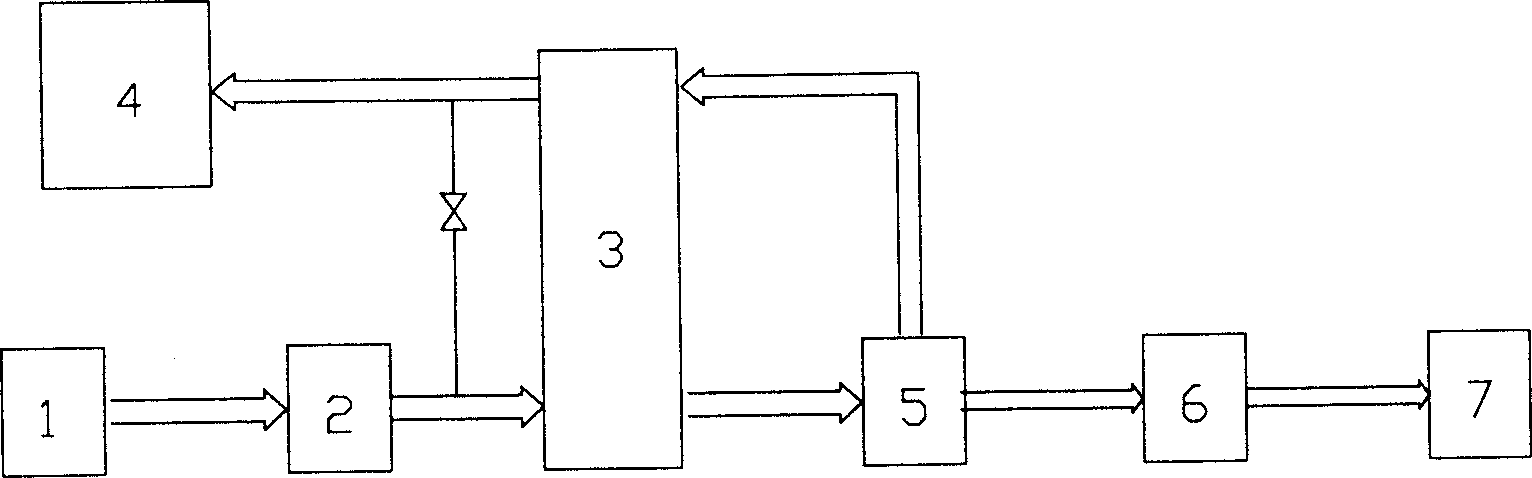

[0036] Such as figure 2 Shown is a process flow diagram of a limestone-gypsum wet desulfurization and desulfurization gypsum resource treatment system. The system includes a coal-fired boiler 1, a limestone-gypsum wet desulfurization system and a desulfurized gypsum resource treatment system. Limestone-gypsum wet desulfurization system includes desulfurization increasing fan 2, flue gas heat exchanger 3, chimney 4, absorption tower 5, hydrodynamic gypsum slurry cyclone 6 and vacuum belt dehydrator 7. The sulfur-containing flue gas with a temperature of 120-150°C in the boiler 1 is pressurized by the desulfurization booster fan 2 and cooled by the flue gas heat exchanger 3, then enters the absorption tower 5, and reacts with the calcium-based absorbent under forced oxidation conditions Calcium sulfate dihydrate is generated to achieve the purpose of flue gas desulfurization. The flue gas after desulfurization is heated by the flue gas heat exchanger 3 and then discharged into...

Embodiment 2

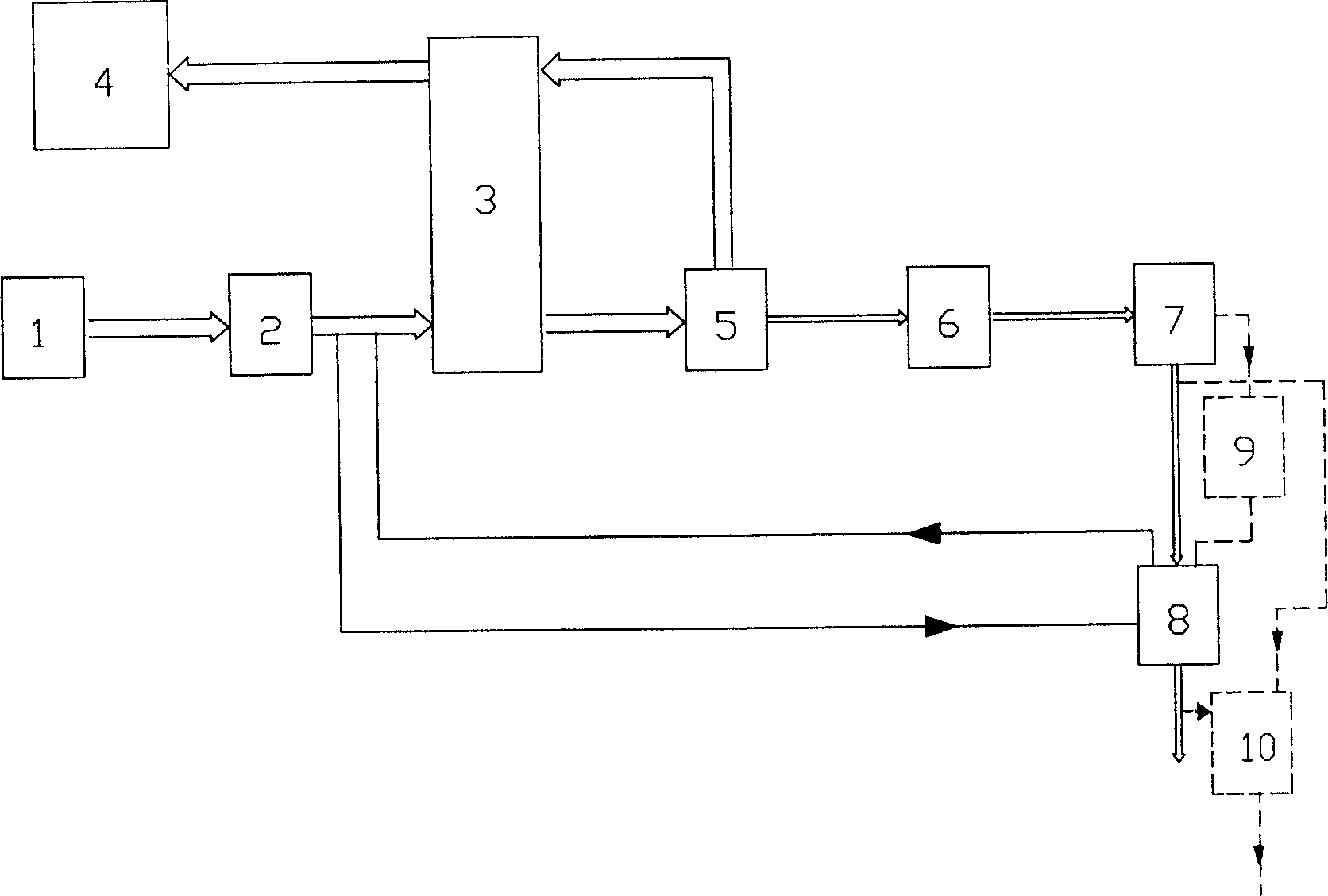

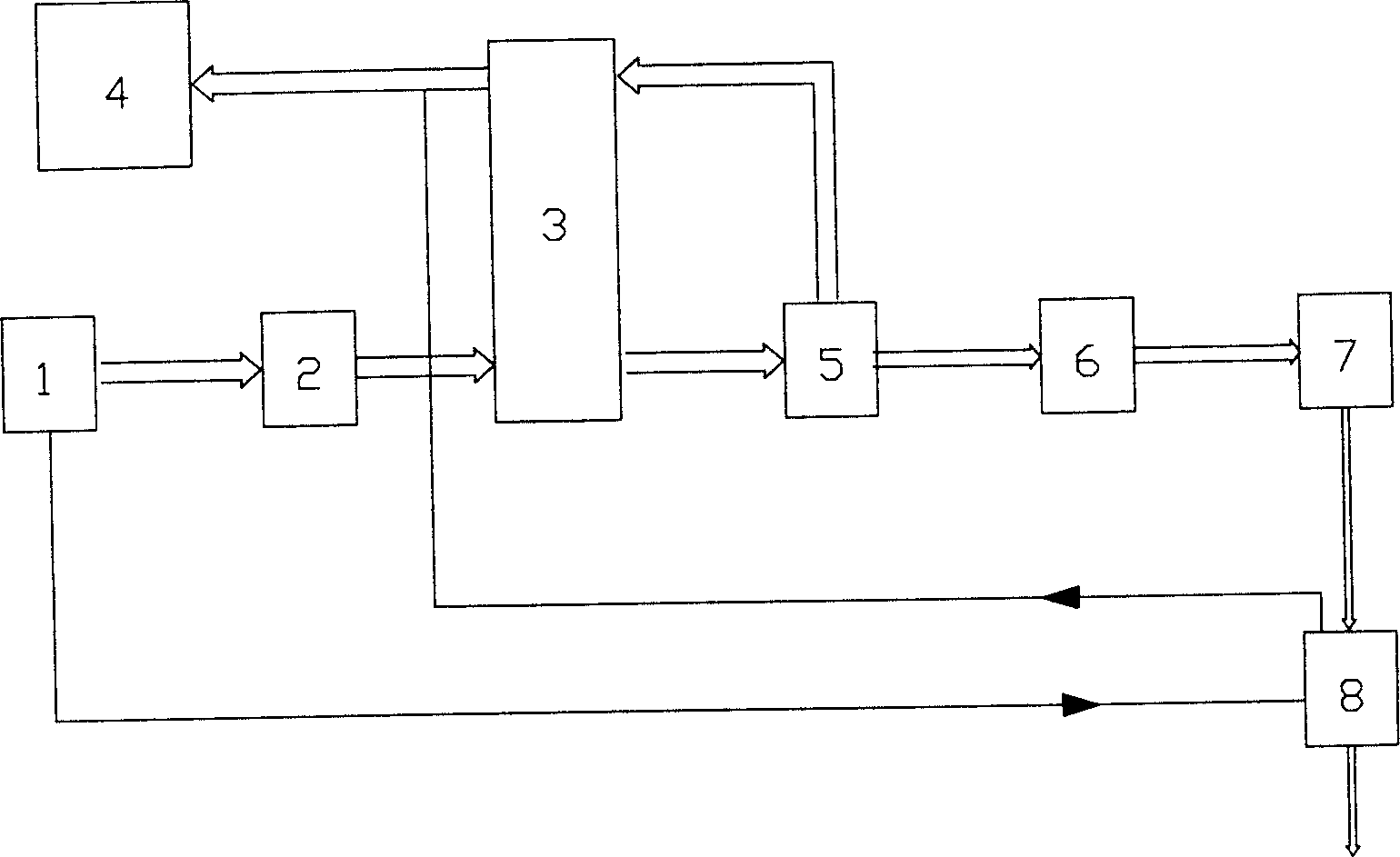

[0041] Such as image 3 As shown, this embodiment is aimed at a process flow for producing anhydrite products. The limestone-gypsum wet desulfurization system in this embodiment is the same as that in Embodiment 1, including desulfurization increasing fan 2, flue gas heat exchanger 3, chimney 4, absorption tower 5, hydrodynamic gypsum slurry cyclone 6 and vacuum belt dehydrator 7. The main equipment of the desulfurization gypsum resource processing system is also the drying calciner 8, the difference is that the hot air with a preheated temperature of about 320°C from the air preheater in the boiler 1 is used as the dehydration drying During the process, the heat source of the calciner 8 is dried, and the powdered desulfurized gypsum is dried and calcined after being adjusted by the electric heater or the temperature of the cold air outlet to remove free water and all bound water to obtain anhydrous gypsum products. The hot air after use is then directly discharged into the ...

Embodiment 3

[0045] Such as Figure 4 As shown, this embodiment is aimed at a process flow for producing α hemihydrate gypsum products. The limestone-gypsum wet desulfurization system in this embodiment is the same as that in Embodiment 1, including desulfurization increasing fan 2, flue gas heat exchanger 3, chimney 4, absorption tower 5, hydrodynamic gypsum slurry cyclone 6 and vacuum belt dehydrator 7. The main equipment of the desulfurization gypsum resource treatment system is also the drying calciner 8, the difference is that an autoclave 11 is also provided at the upstream position of the drying calciner 9 process, and the heat source required by the autoclave 11 is generated by the boiler 1 0.3Mpa saturated steam, and the heat source used by the drying calciner is the flue gas with a temperature of 120-150°C after the desulfurization booster 2 is supercharged and before the flue gas heat exchanger cools down.

[0046] According to the characteristics of the production of α hemihy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com