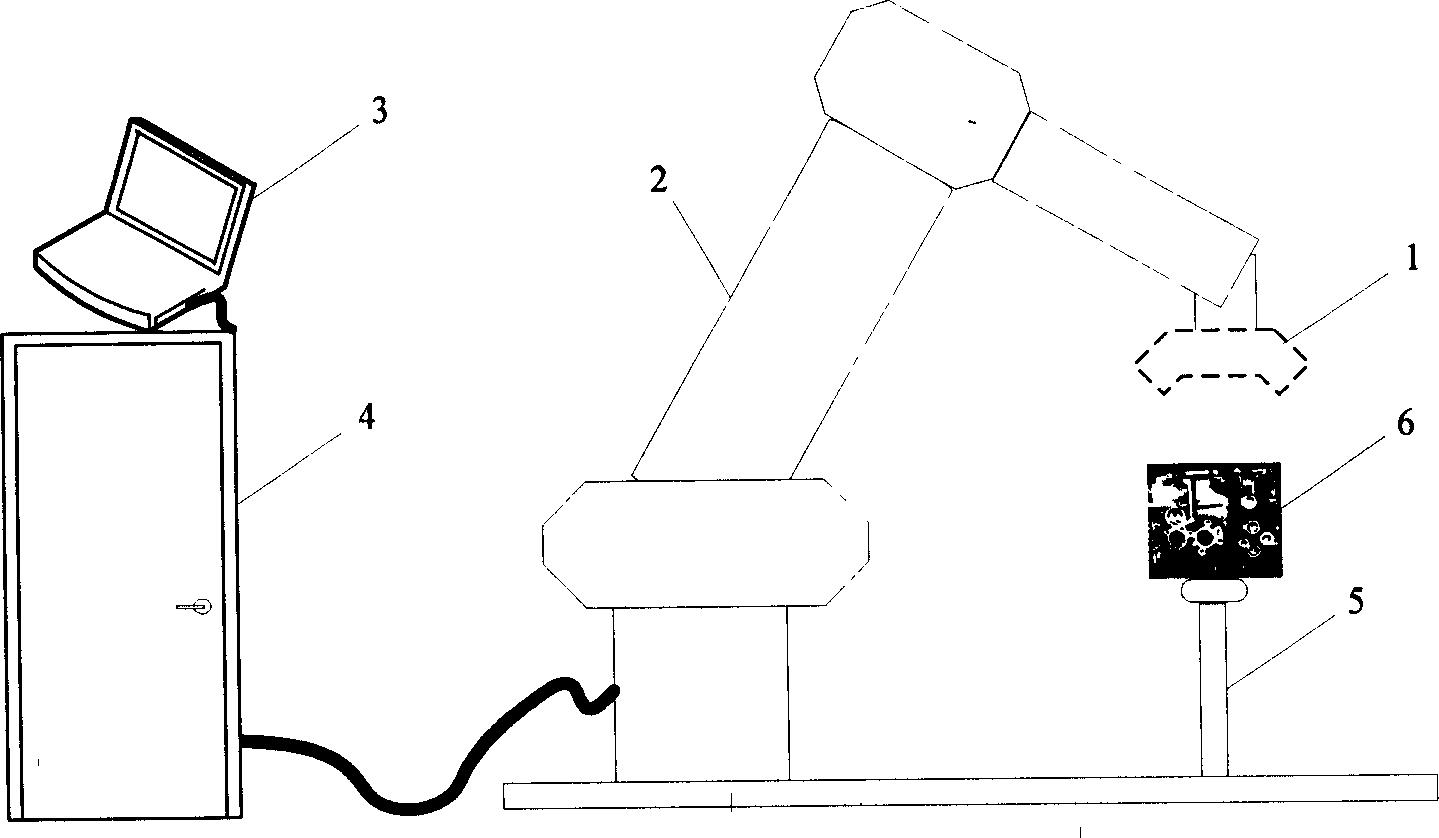

Reverse engineering robot system

A robot system and reverse engineering technology, applied in the field of advanced manufacturing, can solve problems such as difficult data detection, integration of recognition processing and model reconstruction automation, inapplicability to large and complex detection objects, and obstacles to wide application, etc., to achieve a fast and efficient path The effect of planning, strong environmental adaptability and anti-noise ability, and strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

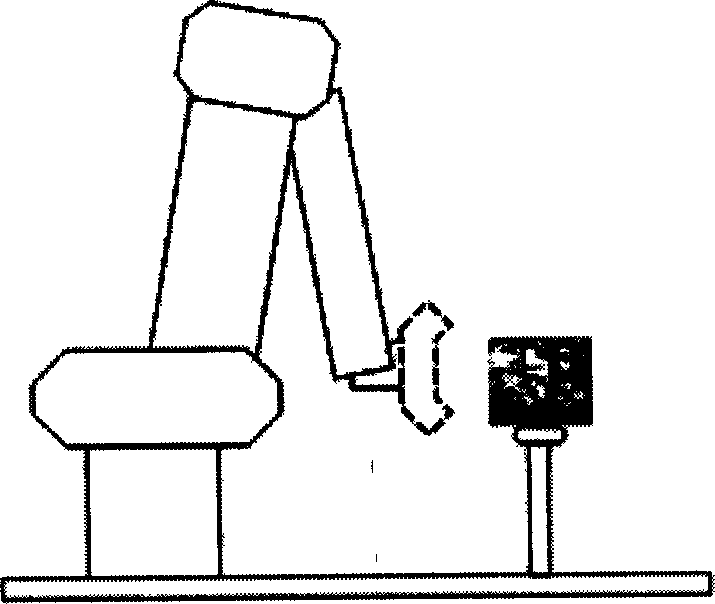

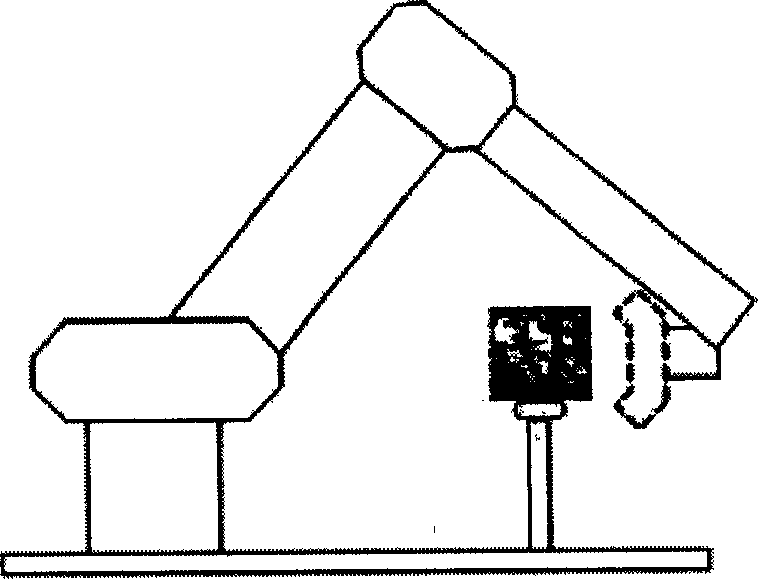

[0059] Through the articulated robot, the non-contact laser scanning head or laser sensor is used to detect the data of the complex unknown surface, and the six degrees of freedom of the robot are used to track the surface during the scanning process through adaptive path planning, as far as possible Ensure that the distance between the laser probe and the measured surface is constant, and the laser incident angle is perpendicular to the surface of the measured point. On the basis of ensuring the detection accuracy, it effectively overcomes the problem of detection blind spots and the problem that the scanning cannot be completed at one time. Use the environmental adaptability, anti-noise ability and workspace ability of industrial robots to solve the problem that traditional equipment is difficult to adapt to the industrial site, and through integrated software design and system process, solve the problem that traditional systems are difficult to realize data detection, identi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com