Optical fibre coherence coupling method for large power semiconductor laser array and optical fibre shaper

A laser array and semiconductor technology, applied in the laser field, can solve problems such as ineffective coupling of beams and interruption of periodic structures, and achieve the effect of improving the degree of phase-locked coherence of the external cavity, reducing loss, and realizing parallel coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

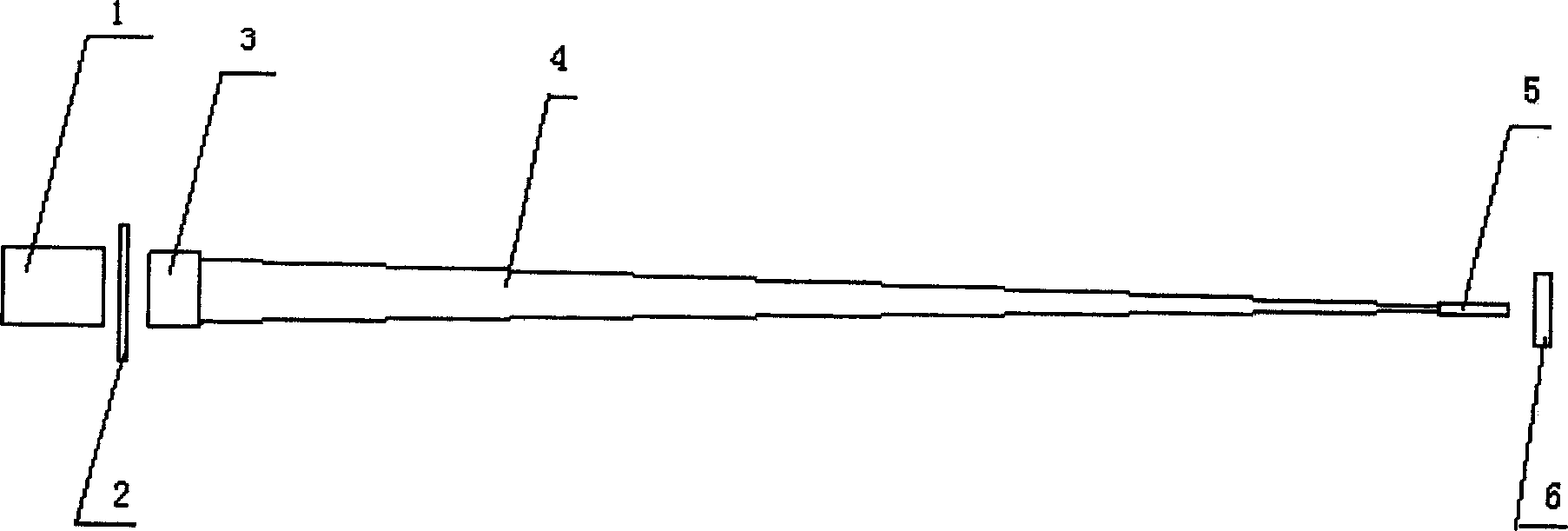

[0022] Below in conjunction with accompanying drawing, specifically illustrate the application of the present invention:

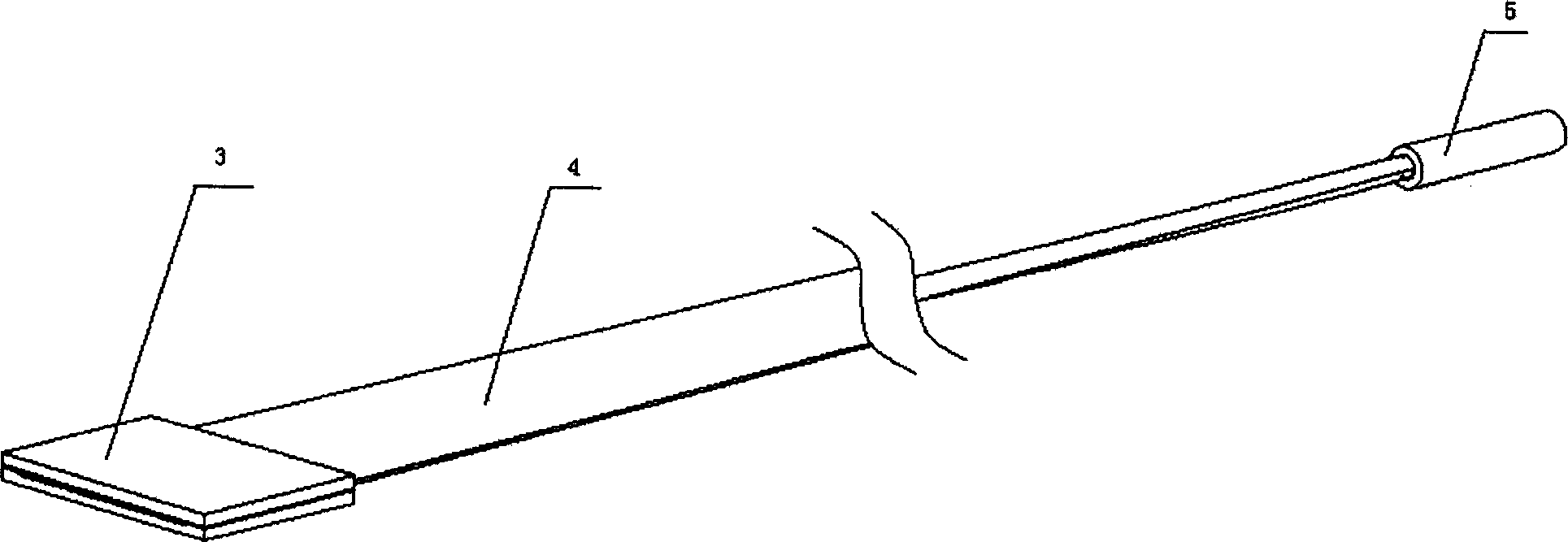

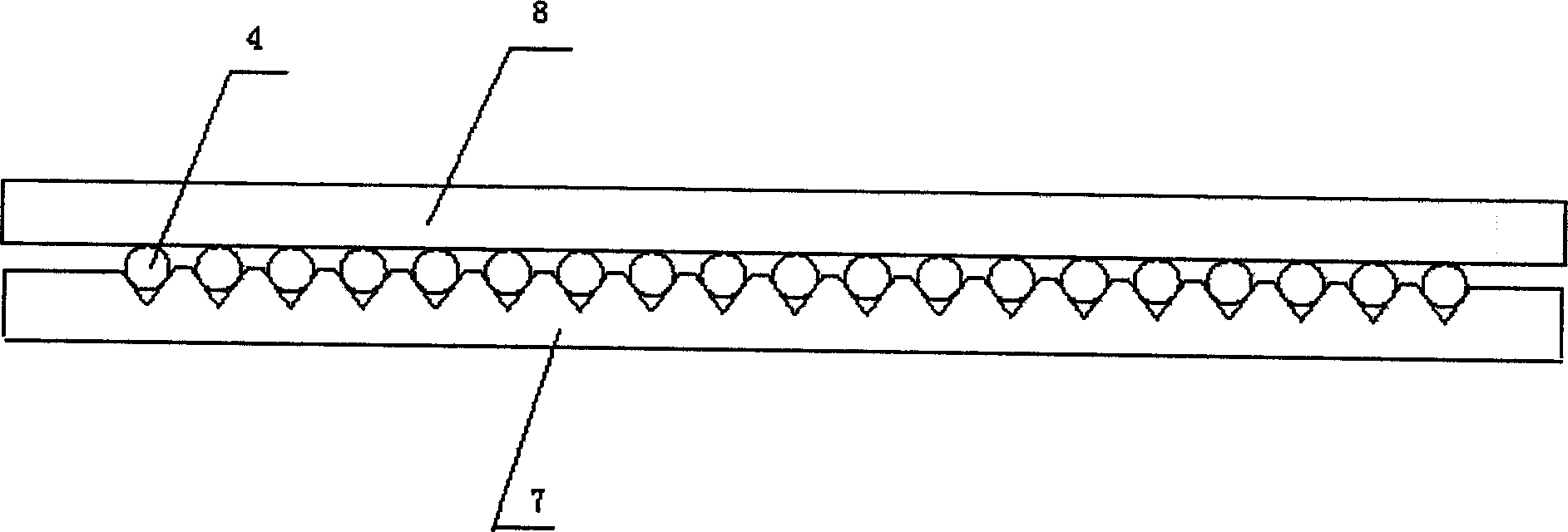

[0023] Fabrication of the optical fiber shaper: Align the fixed sleeve 3, first remove the coating layer from one end of the optical fiber to become a bare fiber, arrange the bare fibers on the V-groove bottom plate, and cover the cover plate (the shape of the cover plate can be a flat cover plate, V groove-shaped cover plate), and then apply curing glue to fix the optical fiber (for a two-dimensional semiconductor laser array, the fixed optical fiber needs to be fixed layer by layer); rearrange one end of the fixing sleeve 5, and remove the coating layer into a bare fiber, the optical fibers are arranged in two dimensions and fixed in the rearrangement fixing sleeve with glue, and the end face of the rearrangement fixing sleeve 5 can be made into a regular quadrilateral, see Figure 4 , can also be made into a circle, see Figure 5 . The optical fiber s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com