Fume purifier

A flue gas purification and hollow shaft technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve the problems of difficult recycling of waste water and sediment, inability to completely separate precipitated dirt, high operating costs, etc. problems, to achieve the effect of reducing harmful sulfur pollution to the atmosphere, reducing construction and operating costs, and reducing burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

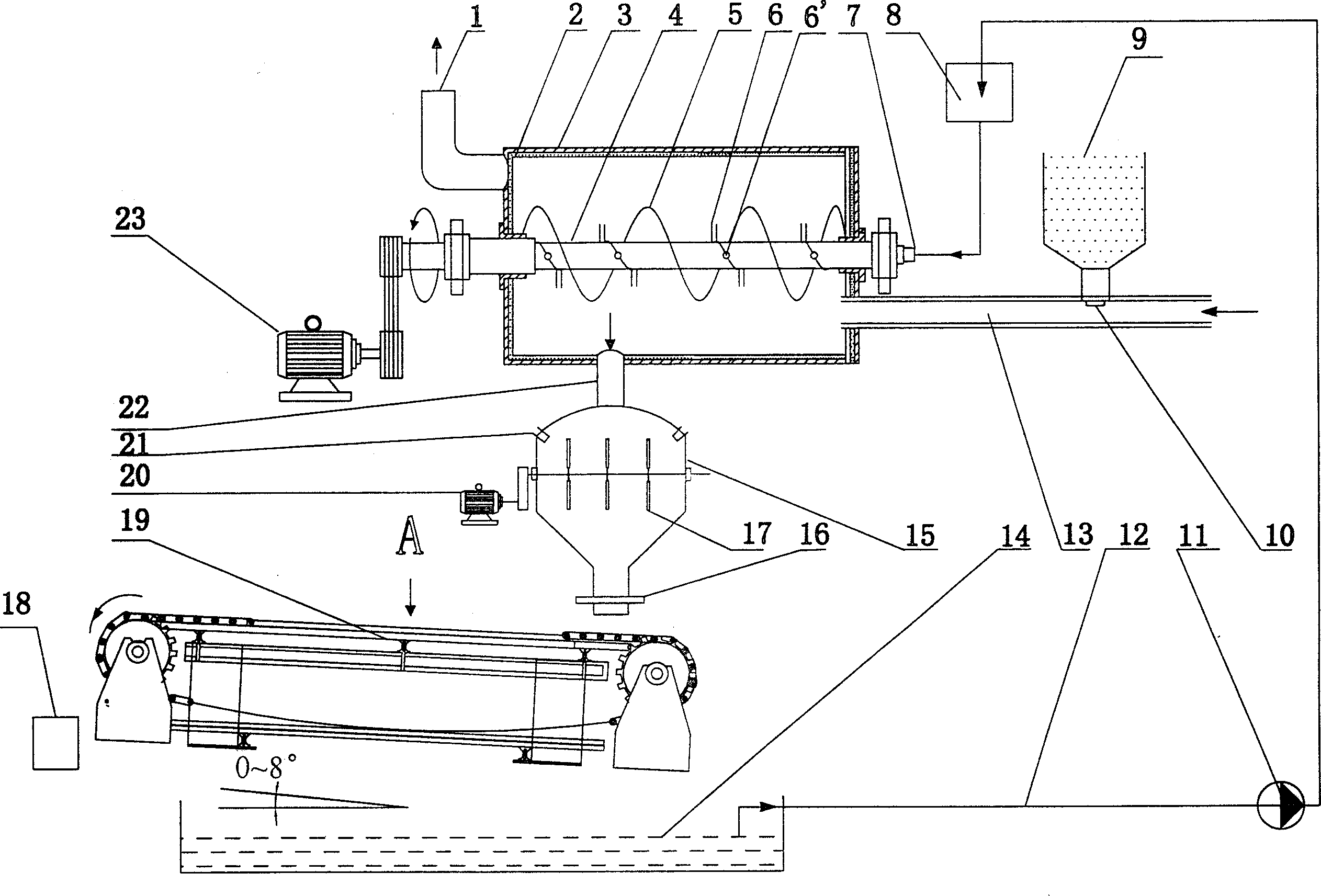

[0009] An air purification device, a calcium oxide powder funnel 9 for desulfurization is installed on the flue 13, and a powder nozzle 10 extending into the flue is arranged at the lower end of the funnel. The nozzle is automatically controlled by a computer. How much, automatically control the injection amount of calcium oxide powder. When working, the sulfur substances in the flue gas react chemically with the calcium oxide powder, that is, CaO+S→CaSO3, so that the sulfur solidifies into small particles and enters the flue gas.

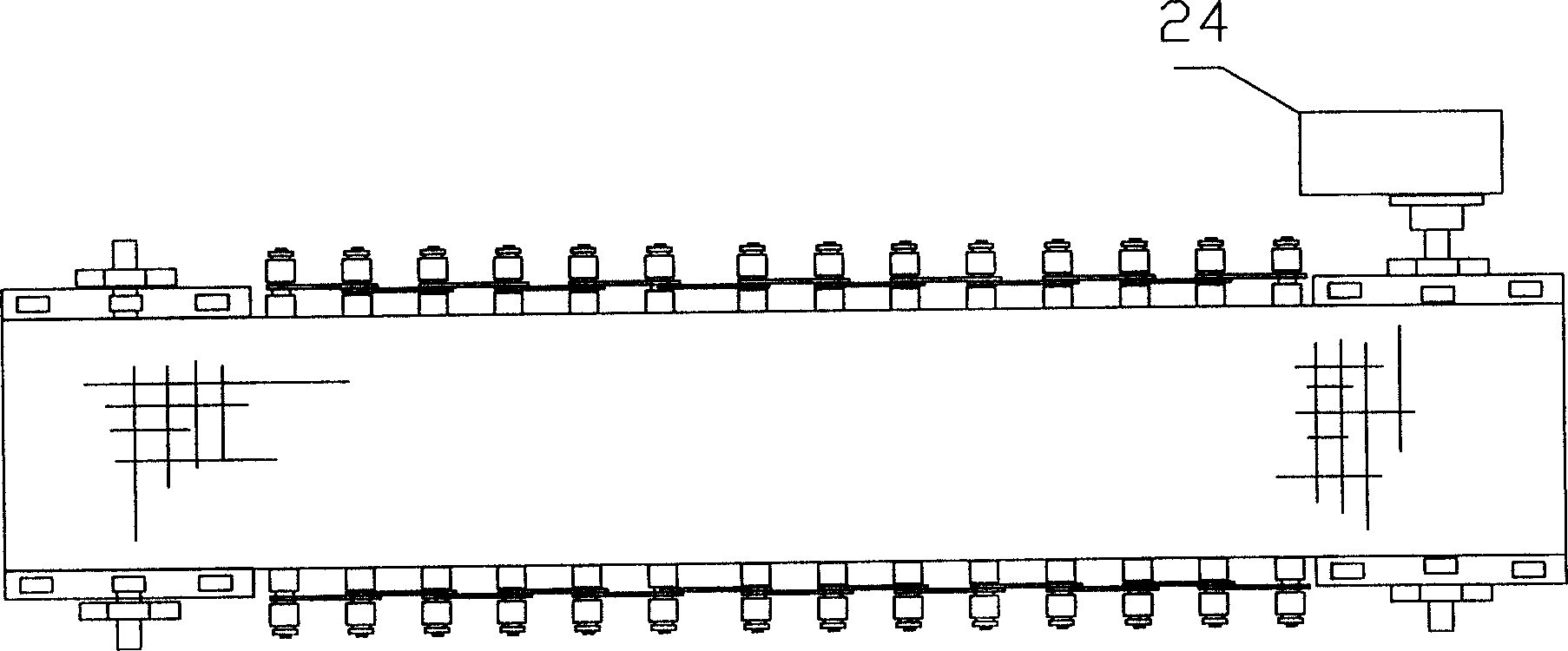

[0010] Washing tub 3 is 1700mm long and 1300mm in diameter, and its lining surface adopts anti-corrosion layer 2. The diameter of hollow shaft 4 is 85mm. The right end and water supply pipe 7 are connected in a flexible seal. The diameters of the cylindrical water nozzles 6 and 6' are 2mm, and the cylindrical water nozzles 6 and the circular hole water nozzles 6' are distributed at intervals. Washing drum motor 23 is 7.5kw, and the rotating speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com