Dry ice cleaning method and dry ice cleaning machine for furnace tube

A technology of dry ice cleaning and furnace tubes, which is applied in the direction of cleaning heat transfer devices, grain processing, lighting and heating equipment, etc., and can solve the problems of economizers affecting heat recovery efficiency, equipment corrosion, and affecting unit operation safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

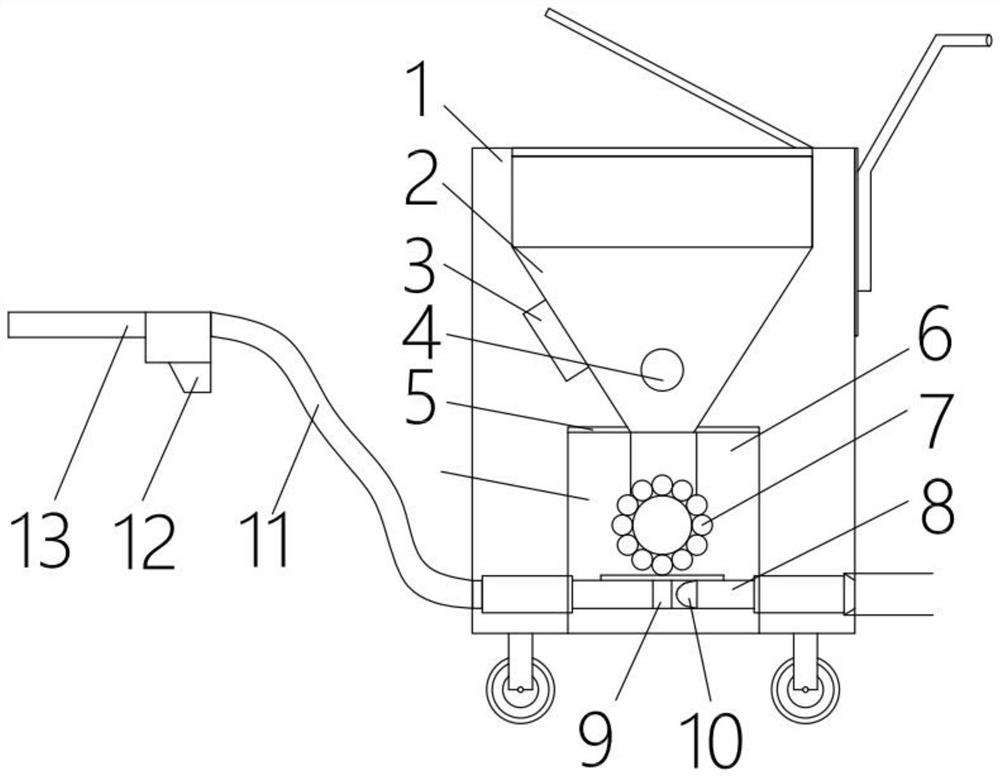

[0026] see figure 1 , the present invention provides the following technical solutions:

[0027] The dry ice cleaning machine for furnace tubes is characterized in that it includes a main box body 1, a conical hopper 2 is arranged inside the main box body 1, a vibrator 3 is installed on the side of the hopper 2, and a stirring roller is arranged inside the hopper 2 4. The outlet of the hopper 2 is provided with a flow sensor 5, and the outlet of the hopper 2 leads to the airlock feeder 7 in the feeding box 6. The outlet of the feeding box 6 is inserted in the radial direction of a high-speed air pipe 8, and the high-speed air pipe 8 is also A T-shaped groove 9 and a high-speed air nozzle 10 are provided. The outlet of the high-speed air pipeline 8 is connected to one end of a hose 11 , and the other end of the hose 11 is equipped with a spray gun 12 .

Embodiment 2

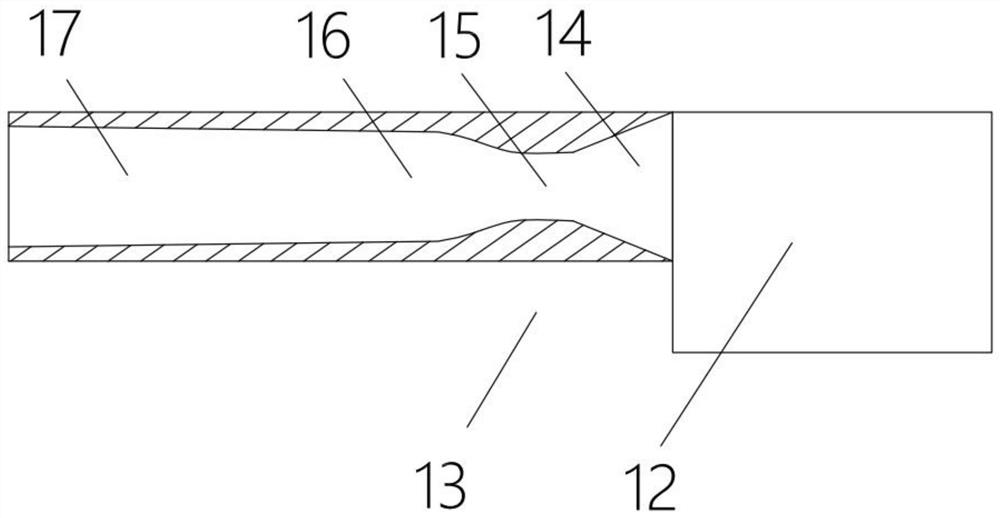

[0029] see figure 2 , the present invention provides the following technical solutions:

[0030] As described in Example 1, the dry ice blasting machine for furnace tubes is characterized in that: the convergent diverter nozzle 13 is sequentially provided with a nozzle joint 14, a nozzle neck 15, a nozzle first diffuser 16 and a nozzle from the tail to the head. The second diffuser 17 .

Embodiment 3

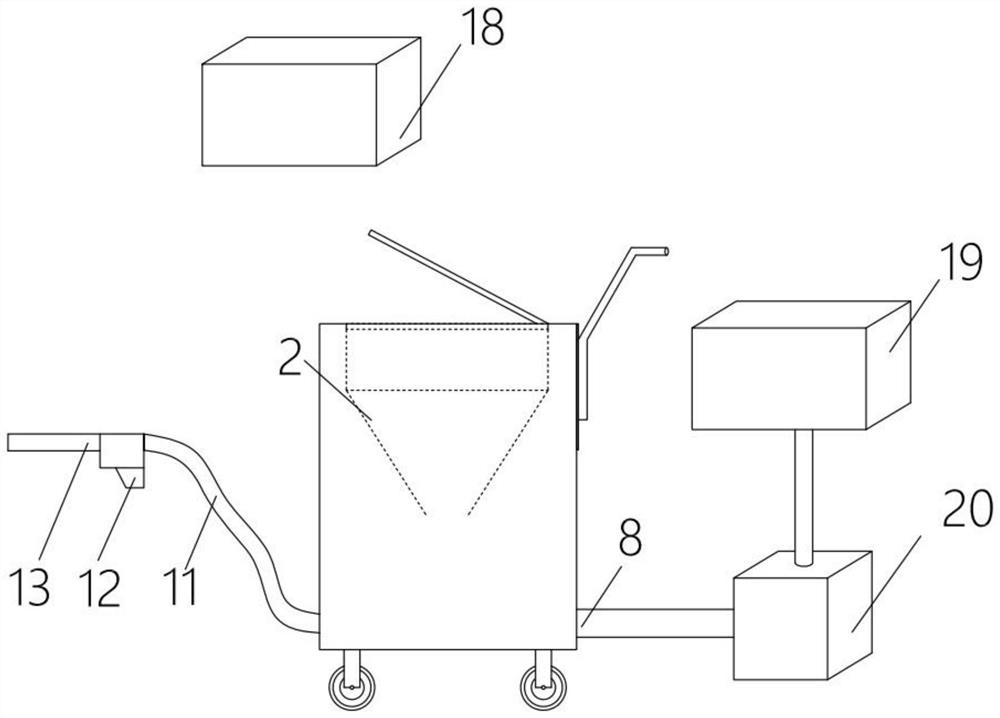

[0032] see image 3 , the present invention provides the following technical solutions:

[0033] The dry ice cleaning method for furnace tubes is characterized in that: the dry ice cleaning machine for the waste heat boiler economizer described in Embodiment 1 or 2 is used in the dry ice cleaning of the economizer of the waste heat boiler.

[0034] Preferably, the dry ice cleaning method for furnace tubes includes the following steps: putting the dry ice in the dry ice incubator 18 into the hopper 2, and transporting the compressed air to the high-speed air pipeline 8 after being processed by the air compressor 19 and the dryer 20 in sequence, Aim the converging and splitting nozzle 13 at the fouling place of the economizer, and run the dry ice blasting machine to start cleaning.

[0035] It solves the problem that after long-term use of the waste heat boiler, the fouling of the economizer seriously affects the heat recovery efficiency and even affects the safety of the unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com