Soil cold-storage and coupled integrating system of hot pump

A coupled heat pump and integrated system technology, applied in the field of integrated systems, can solve the problems of large initial investment, complex system management and control, and insufficient output of the system for long-term operation, to solve the problem of large footprint, improve operating performance, and solve The effect of underefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

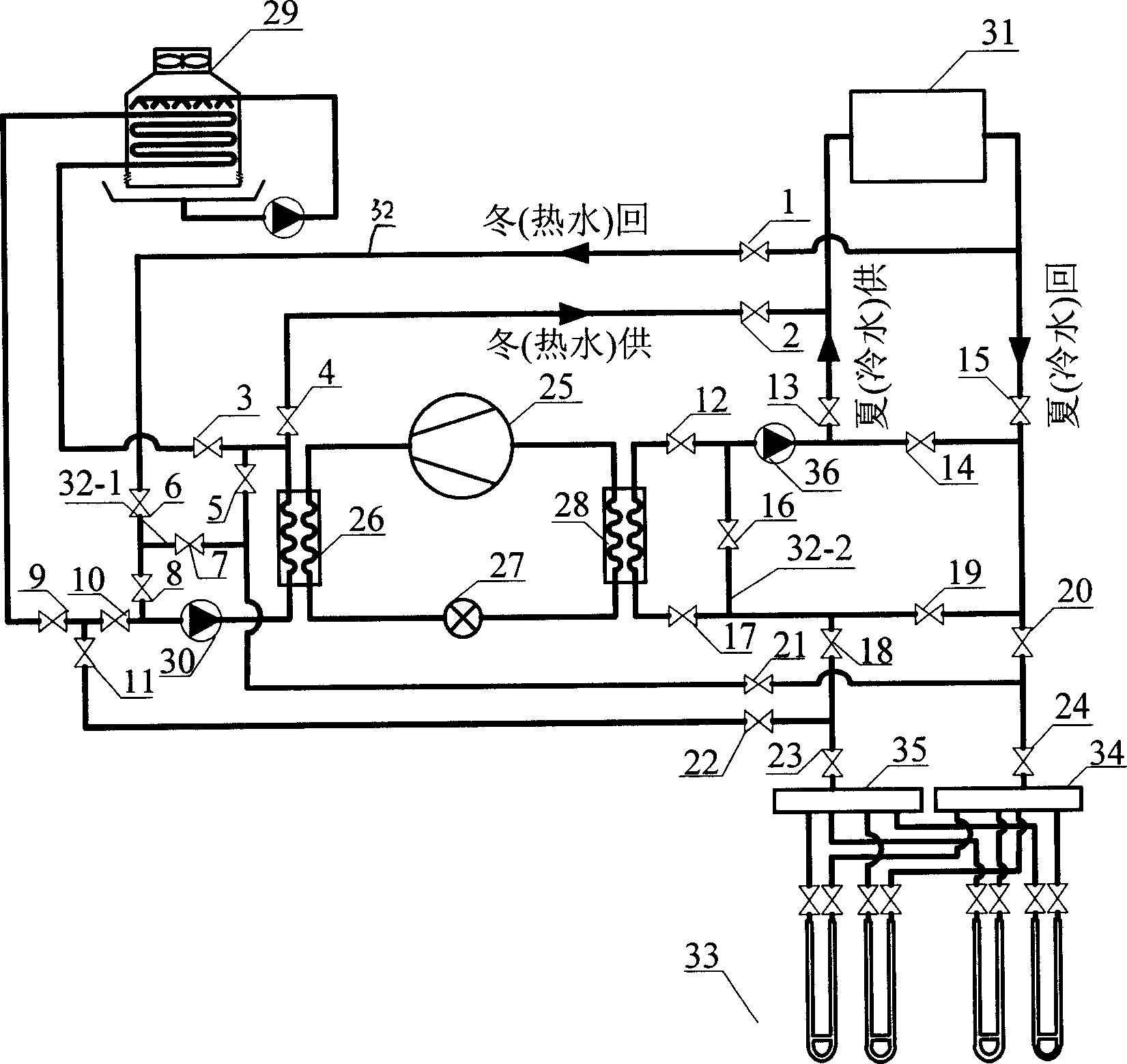

[0013] Specific implementation mode one: refer to figure 1 , this embodiment includes a refrigeration equipment composed of a compressor 25, a condenser 26, a throttle valve 27 and an evaporator 28, a cooling tower 29 and a water pump. Each connecting pipeline 32 is connected with a valve, and it also includes an underground buried pipe heat exchanger 33, and the water inlet and outlet of the underground buried pipe heat exchanger 33 are respectively provided with a water collector 34 and a distribution pipe. Water container 35;

[0014] Between the condenser 26 of the refrigerating equipment and the cooling tower 29, between the condenser 26 and the underground pipe heat exchanger 33, between the condenser 26 and the user 31, a loop is formed through pipeline connections; the evaporator 28 and the The users 31, the evaporator 28 and the underground pipe heat exchanger 33 are all connected to form a loop through pipelines; the underground pipe heat exchanger 33 and the user 3...

specific Embodiment approach 2

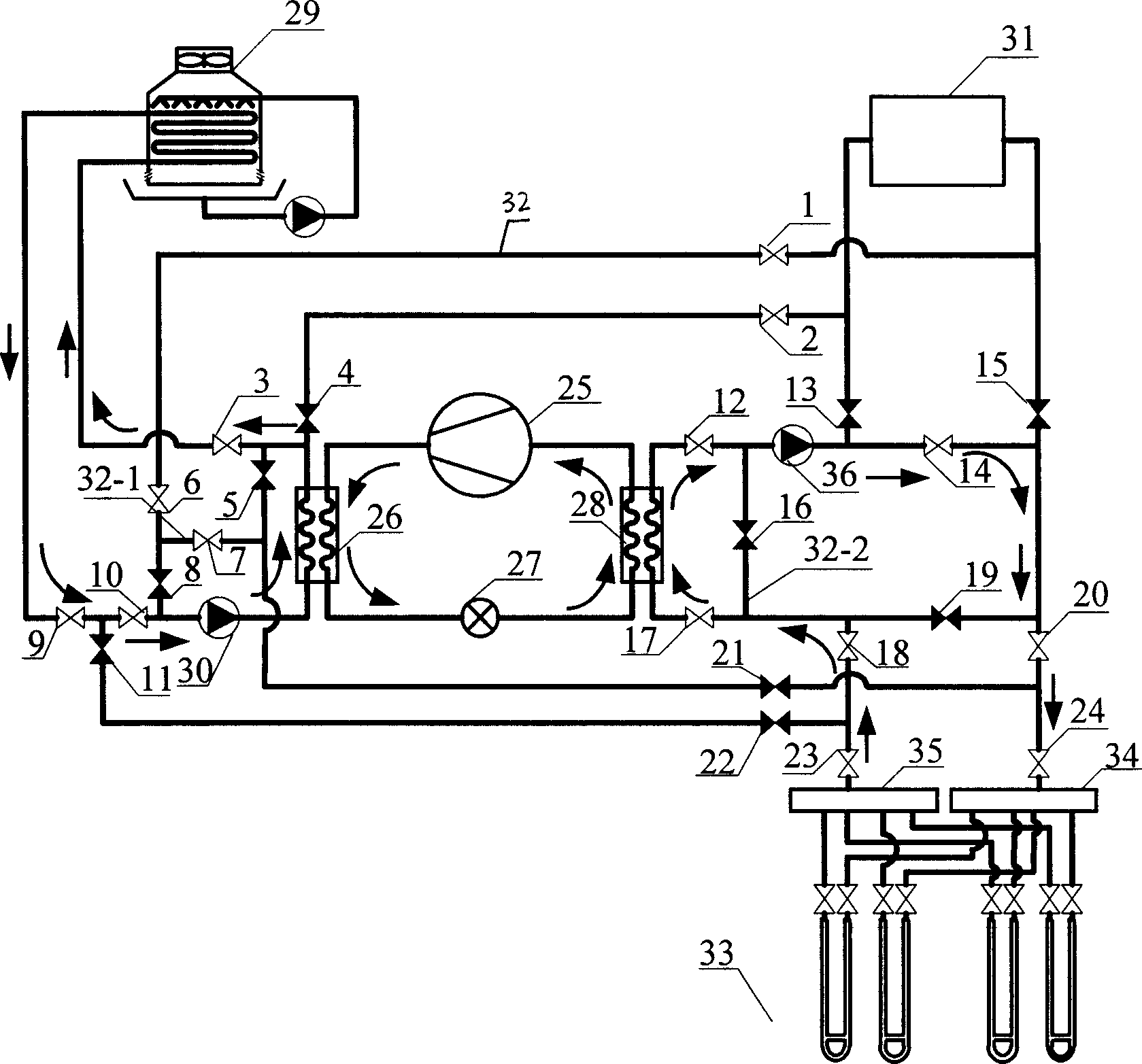

[0024] Specific implementation mode 2: Since the system fully integrates the advantages of the technical elements of cold storage technology and soil-coupled heat pump technology, it should give full play to the advantages of cold storage technology and make full use of the power resources in low-peak periods when the air conditioner is running in summer. Avoid peak power consumption, cut peaks and fill valleys, reduce system operating costs, store all or part of the air-conditioning cooling capacity used by buildings in the underground soil, and realize the transfer of air-conditioning power loads.

[0025] This implementation mode is the soil cold storage operation mode, which can be selected to work during low power consumption periods. At this time, the low-temperature freezing liquid is prepared by controlling the switches of the valves at different positions, and the low-temperature freezing liquid is circulated in the pipeline of the buried pipe heat exchanger 33 to exch...

specific Embodiment approach 3

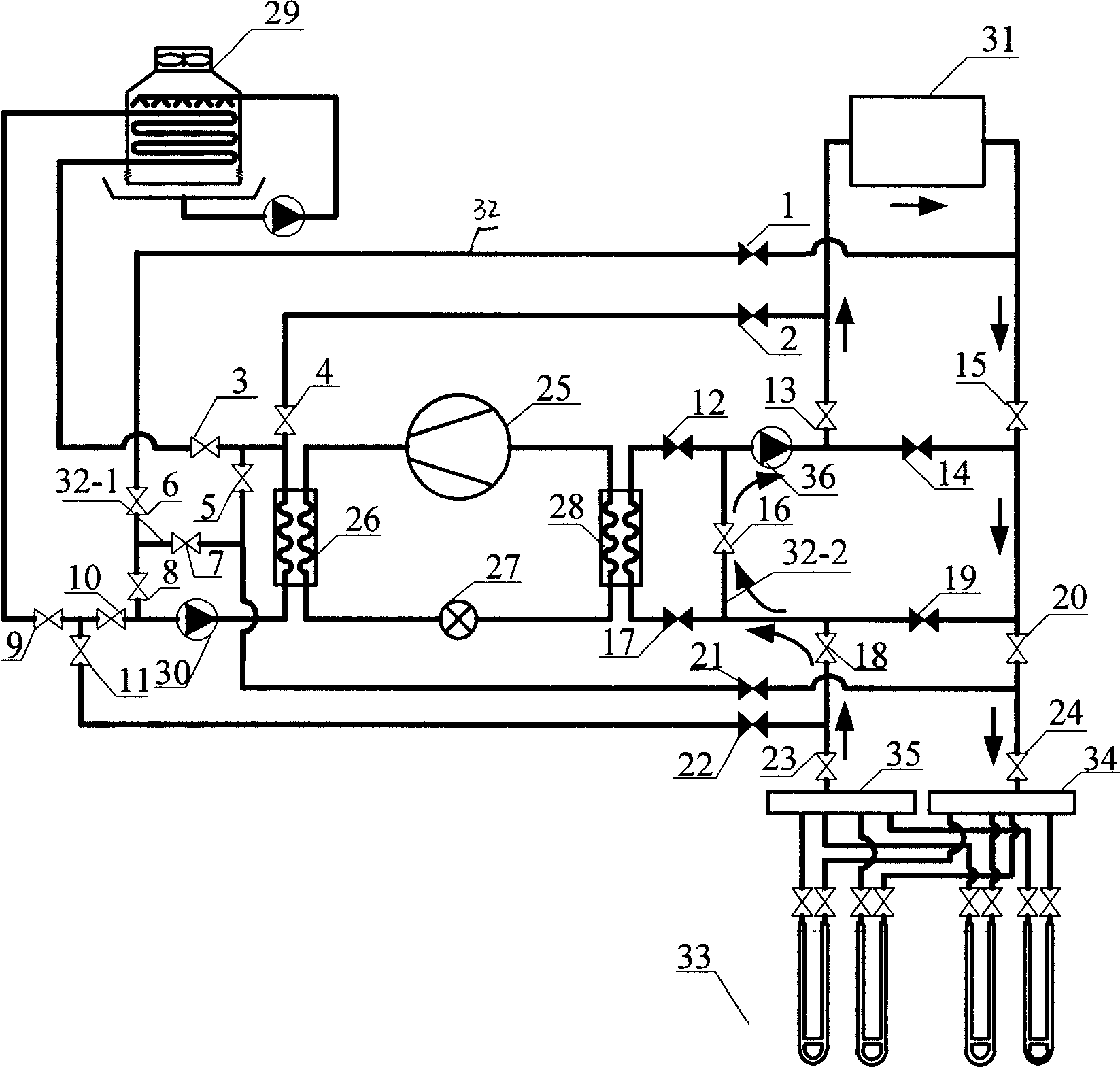

[0032] Specific implementation mode 3: This implementation mode is the soil cooling operation mode, and it can be selected to work during peak hours of electricity consumption. During the power peak period, the chiller is shut down, and the brine (antifreeze) is circulated in the underground pipe heat exchanger 33 by turning on the circulating water pump on the side of the user 31, and the cold energy stored in the soil during the low valley period is extracted. For air conditioning system use.

[0033] refer to image 3 , the opening and closing of the valve during this working process is:

[0034] Close No. 1 valve 1, No. 2 valve 2, No. 14 valve 14, No. 19 valve 19, No. 17 valve 17, No. 12 valve 12, No. 21 valve 21 and No. 22 valve 22, and close No. 13 valve 13 and No. 15 Valve 15, valve 20, valve 20, valve 24, valve 24, valve 23, valve 18, valve 16 and valve 16 are opened, even if the loop between the buried pipe heat exchanger 33 and the user 31 is unblocked;

[0035] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com