Automatic tracking control method for submerged-arc welding seam

A technology of automatic tracking and control method, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of visual sensor tracking system welding spatter, high metal surface requirements, and inability to guarantee tracking accuracy, etc., to achieve the tracking effect. Good, high control accuracy and sensitivity, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

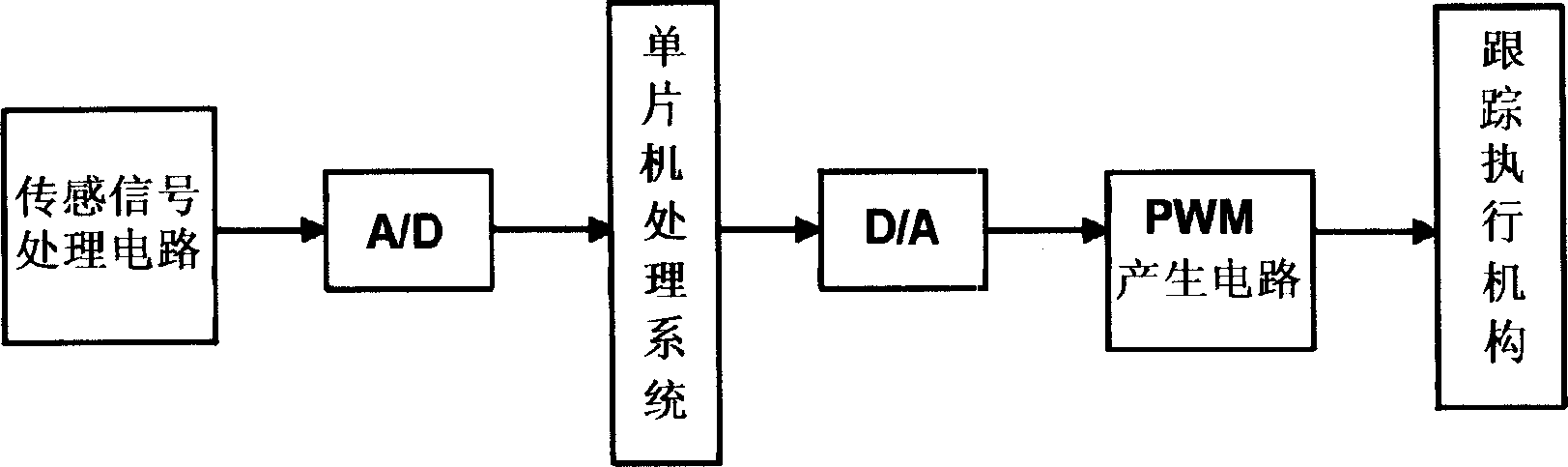

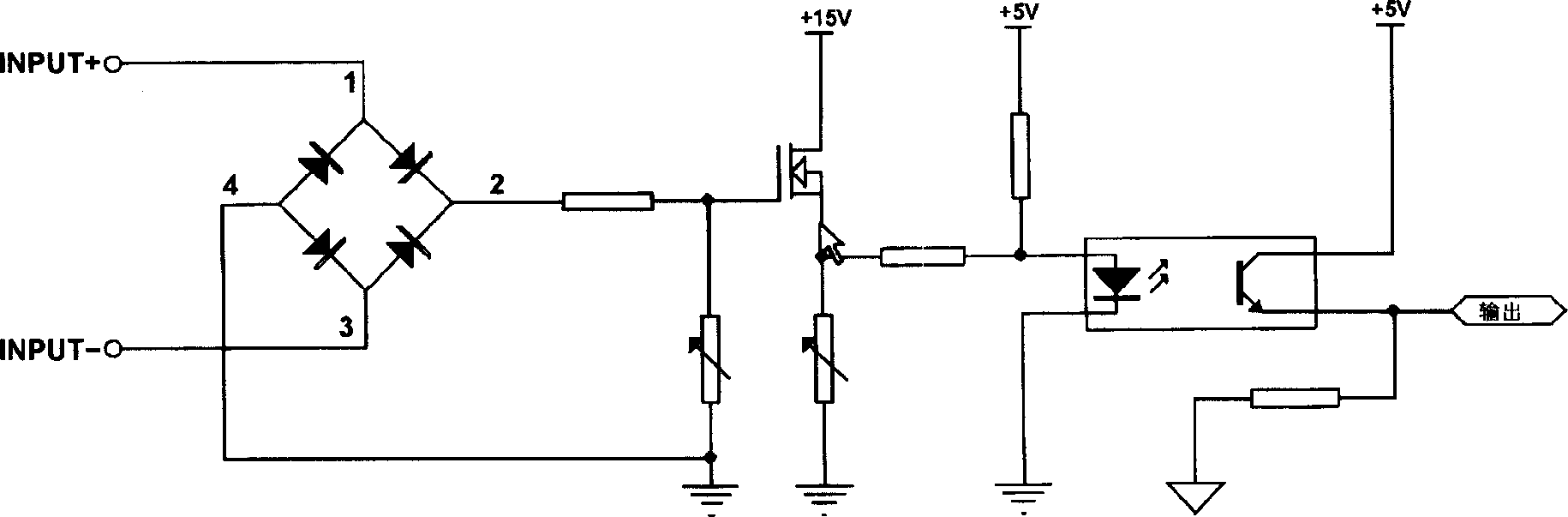

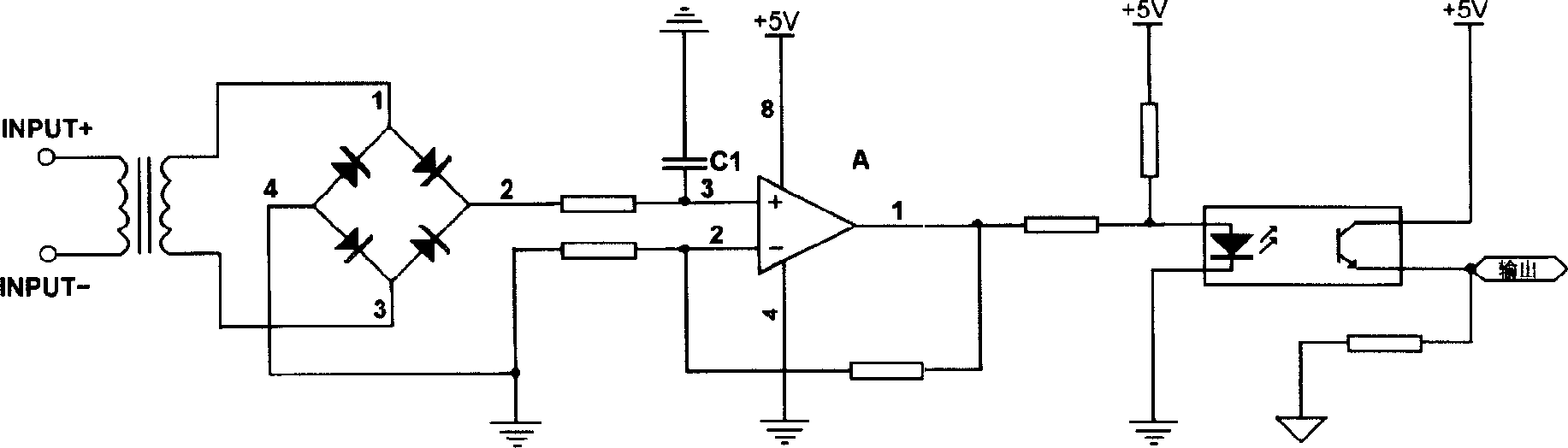

[0015] The invention uses a DC motor to drive the welding torch to form an oscillating arc, and reciprocates linear scanning above the weld bead. The scanning distance can be adjusted according to the thickness of the workpiece and the size of the groove, generally 10-20mm, and the scanning frequency is adjustable from 1-3Hz. . The two-dimensional adjustment mechanism of the machine head adopts a stepping motor and a cross slider mechanism with good stability and convenient control. The present invention utilizes an AC welding power supply whose external characteristic is a descending characteristic, and according to the basic principle of the arc sensor: the welding current parameter change caused by the distance change between the welding torch and the workpiece is used to detect the distance height and the left and right deviation, and the welding cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com