Composite chamber adjustable Raman optical fiber laser

A fiber laser, composite cavity technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as difficult to fully meet actual needs, limited tuning range, complex process, etc., to achieve flexible and adjustable output wavelength, temperature The effect of good stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

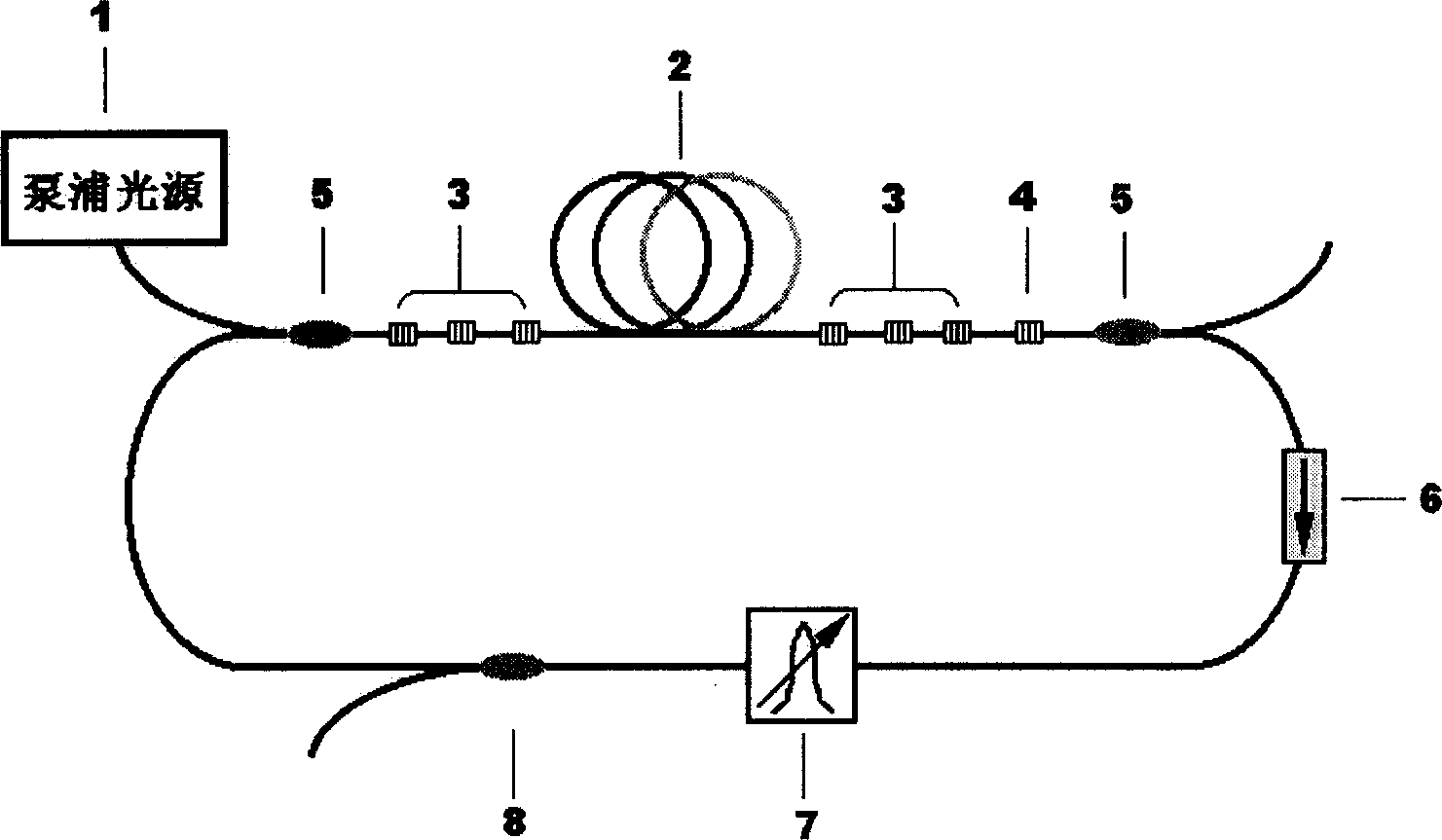

[0021] The pumping source 1 of the 1.55μm band composite cavity tunable Raman fiber laser adopts a high-power fiber laser with an output wavelength of 1070nm, the gain fiber adopts phosphosilicate Raman fiber 2, and the nested cascaded linear cavities are symmetrically distributed in the Raman Three pairs of all-reflection fiber gratings 3 on both sides of the fiber, one total-reflection grating 4 with a center wavelength of 1070 nm and a Raman fiber. The central wavelengths of the three pairs of total reflection gratings are 1247nm, 1328nm and 1421nm respectively. The broadband tunable ring cavity includes 1070 / 1550WDM coupler 5, 1550nm isolator 6, 1.55μm band narrowband tunable filter 7, 1550nm fiber coupler 8 and Raman fiber 2.

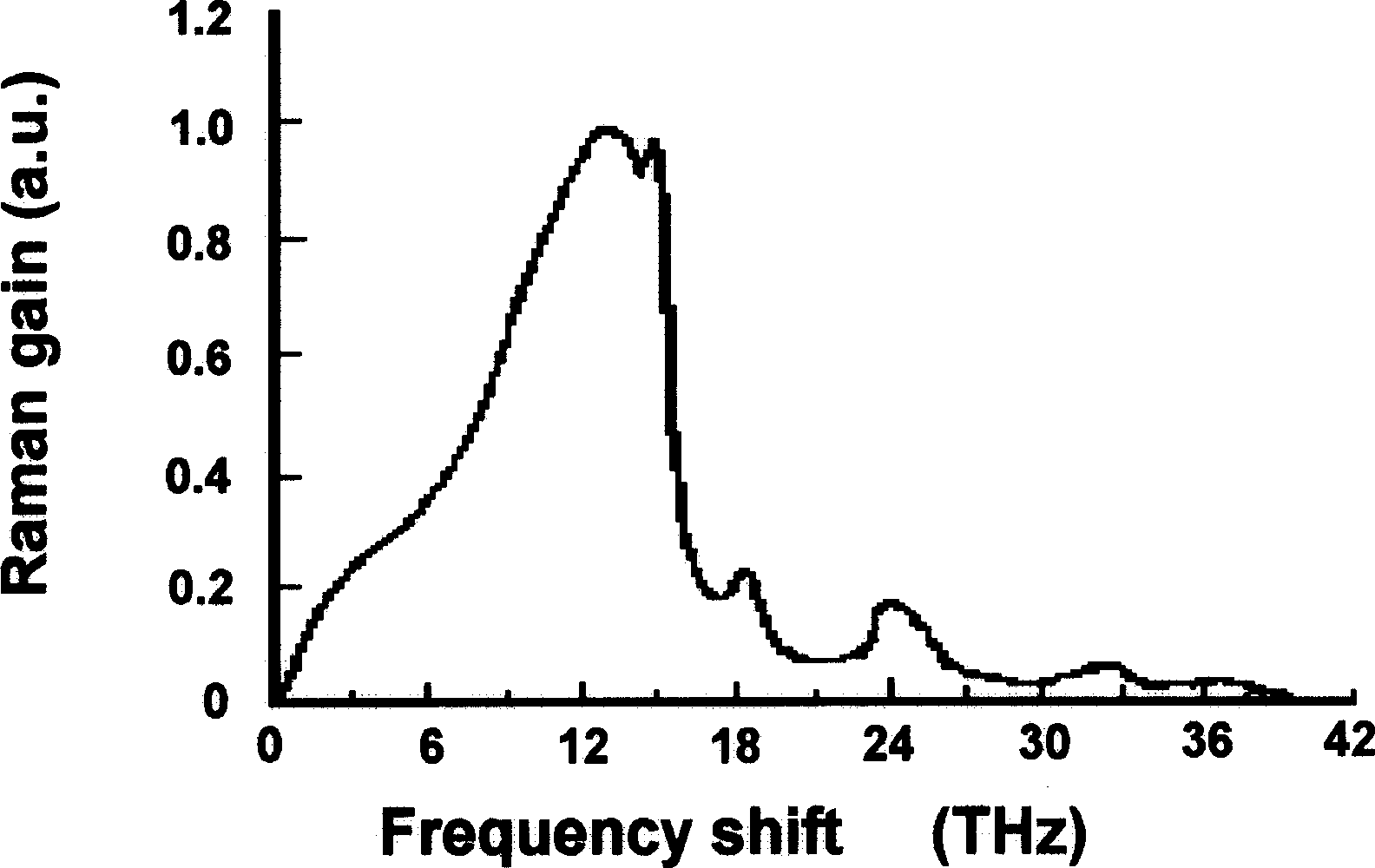

[0022] This tunable laser uses the Raman scattering effect in the fiber to obtain high-power broadband tunable laser output in the 1.55μm band. The gain medium of the tunable laser adopts phosphorus-silicon Raman fiber as the gain medium, and util...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com