Negative C-plate type optical anisotropic film comprising poly cycloolefin and method for preparing the same

一种光学各向异性、聚环烯烃的技术,应用在光学、光学元件、非线性光学等方向,能够解决催化剂中毒等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention provides a negative C-plate type optically anisotropic film, especially a film comprising a cycloolefin addition polymer prepared by addition polymerization of a norbornene-based monomer, a method for preparing the same, and a film comprising the film LCD Monitor.

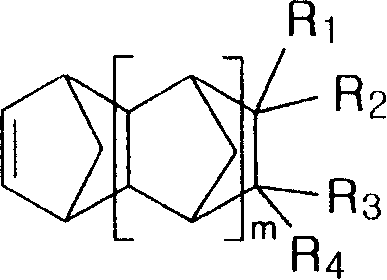

[0056] The cycloolefin addition polymer obtained by addition polymerization of a norbornene-based monomer of the present invention includes a homopolymer obtained by addition polymerization of a norbornene-based monomer represented by Chemical Formula 1 below, and Another copolymer obtained by addition copolymerization of monomers:

[0057] chemical formula 1

[0058]

[0059] In Chemical Formula 1,

[0060] m represents an integer from 0 to 4;

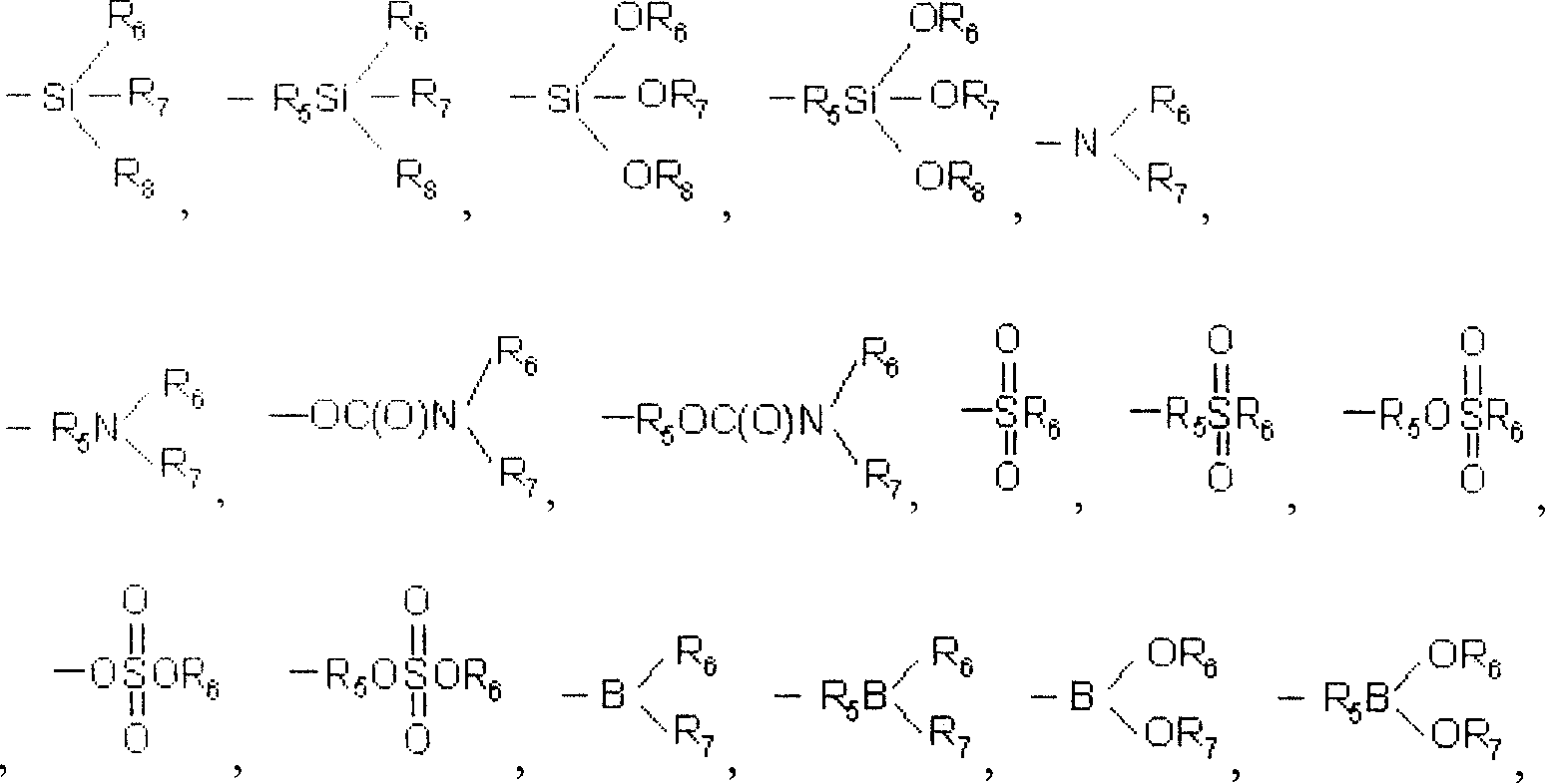

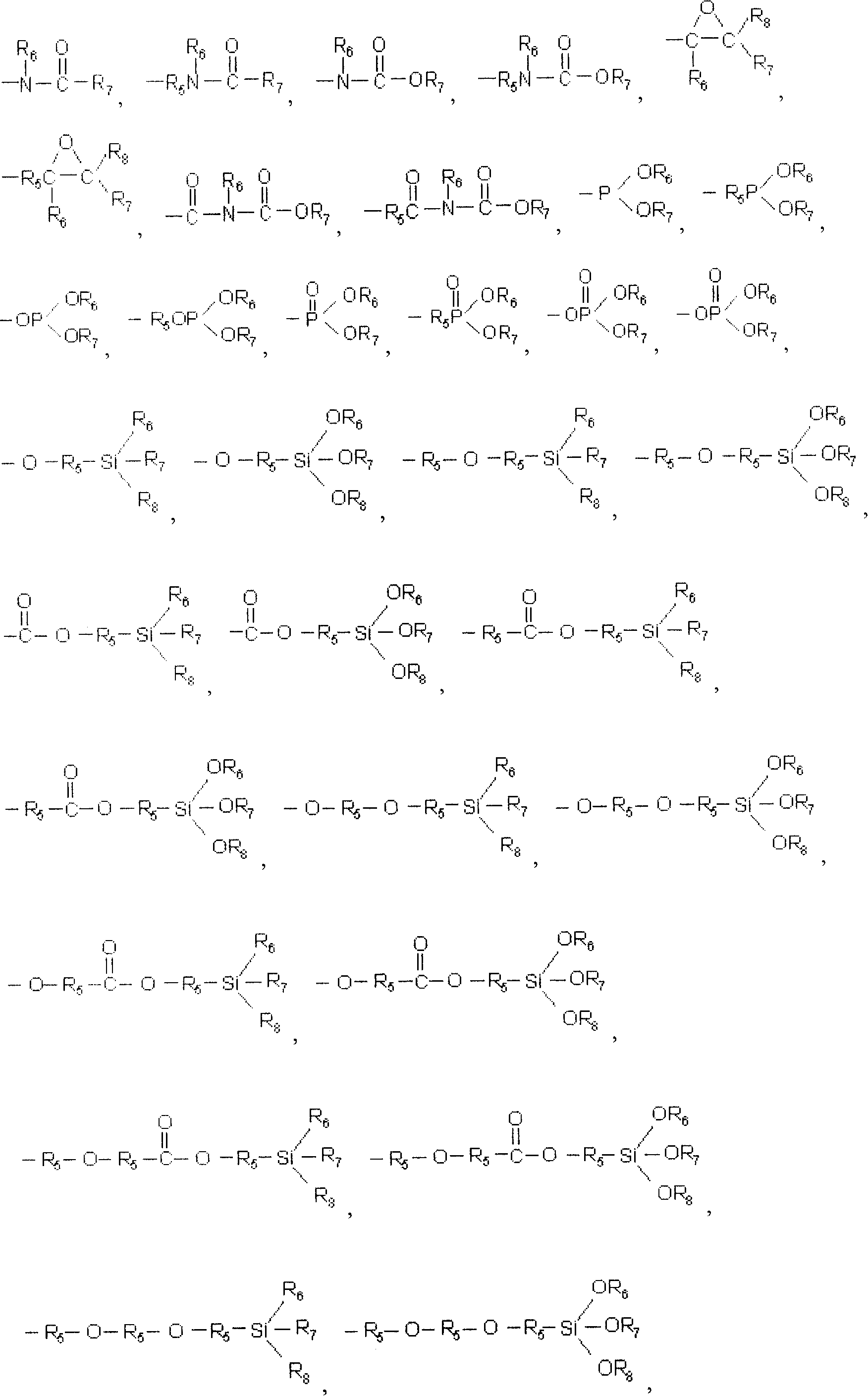

[0061] R 1 , R 2 , R 3 and R 4 Hydrogen alone or together; Halogen; C 1 to C 20 Alkyl, alkenyl or vinyl of linear or branched chain structure; C 4 to C 12 Hydrocarbyl substituted or unsubstituted cycloalkyl; C 6 to C 40 Hydrocar...

preparation Embodiment 1

[0158] Preparation Example 1: Polymerization of norbornene carboxylate methyl ester

[0159] The norbornene carboxylate methyl ester monomer and purified toluene were added to the polymerization reactor in a weight ratio of 1:1.

[0160] 0.01 mol% (relative to monomer content) Pd(acac) dissolved in toluene 2 and 0.01 mol% (relative to the monomer content) of tricyclohexylphosphine as a catalyst, and 0.02 mol% (relative to the monomer content) dissolved in CH 2 Cl 2 Tetrakis(pentafluorophenyl) borate dimethylaniline in is added to the reactor as a cocatalyst. The reaction was carried out under stirring at 80°C for 20 hours.

[0161] After the reaction is finished, the reaction mixture is added to excess ethanol to obtain a white copolymer precipitate. The precipitate was filtered with a glass funnel, and then the collected copolymer was dried in a vacuum oven at 65° C. for 24 hours to obtain a norbornene carboxylate methyl ester polymer (PMeNB).

preparation Embodiment 2

[0162] Preparation Example 2: Polymerization of Norbornene Carboxylate Butyl Ester

[0163] The butyl norbornene carboxylate monomer and purified toluene were added to the polymerization reactor at a weight ratio of 1:1.

[0164] 0.01 mol% (relative to monomer content) Pd(acac) dissolved in toluene 2 , and 0.01 mol% (relative to monomer content) of tricyclohexylphosphine as a catalyst, 0.02 mol% (relative to monomer content) dissolved in CH 2 Cl 2 Tetrakis(pentafluorophenyl) borate dimethylaniline in is added to the reactor as a cocatalyst. The reaction was carried out under stirring at 80°C for 20 hours.

[0165] After the reaction was completed, the reaction mixture was added to excess ethanol to obtain a white copolymer precipitate. The precipitate was filtered with a glass funnel, and then the collected copolymer was dried in a vacuum oven at 65° C. for 24 hours to obtain a norbornene carboxylate butyl ester polymer (PBeNB).

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com