Method of preparing low sodium carnallite by blending halogen

A technology of carnallite and carnallite, which is applied in the direction of magnesium halide, alkali metal chloride, magnesium chloride, etc., can solve the problem of no industrial application prospect, rising cost of low-sodium carnallite, and increasing consumption of bischofite. Large and other problems, to achieve the effect of broad prospects for industrial application, low production costs, and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

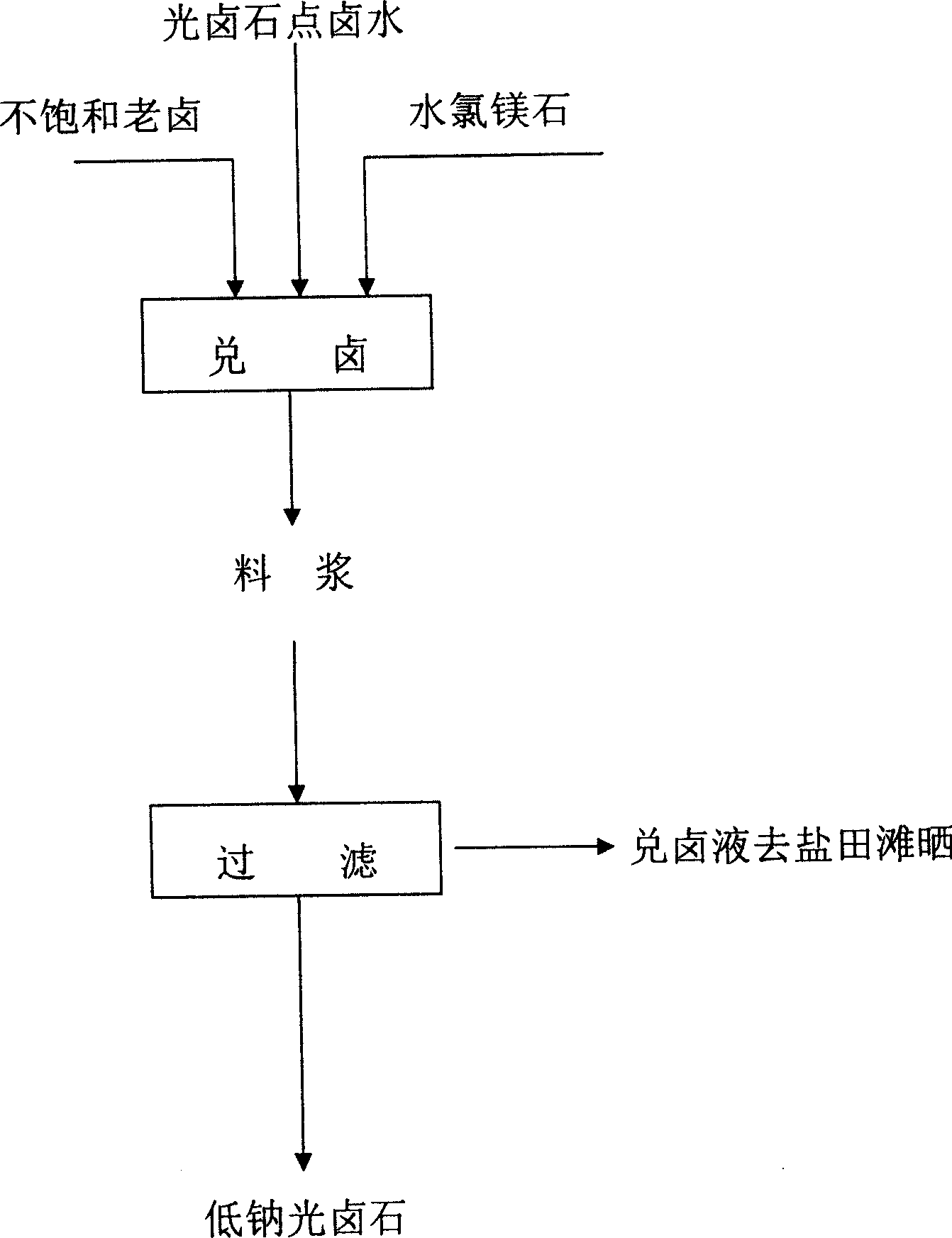

Method used

Image

Examples

Embodiment 1

[0016] Example 1. A method for preparing low-sodium carnallite by mixing brine. The bischofite obtained by drying on the beach in salt fields and evaporating naturally and unsaturated old brine is mixed in a brine mixing container until the mixture of bischofite and unsaturated old brine Magnesium ion Mg ++ The percentage content of carnallite is 8.0%; then add carnallite point brine to the mixture to carry out the halogen crystallization reaction, and filter to obtain low-sodium carnallite; wherein, the composition of the added carnallite point brine is potassium ion K + The percentage content is 0.5%, magnesium ion Mg ++ The percentage content of is 5.0%; The weight ratio of mixture and carnallite point brine is 1:1.

Embodiment 2

[0017] Example 2. A method for preparing low-sodium carnallite by mixing brine. The bischofite obtained by drying on the beach in salt fields and evaporating naturally and unsaturated old brine is mixed in a brine mixing container until the mixture of bischofite and unsaturated old brine Magnesium ion Mg ++ The percentage content of carnallite is 8.5%; then add carnallite point brine to the mixture to carry out the halogen crystallization reaction, and filter to obtain low-sodium carnallite; wherein, the composition of the added carnallite point brine is potassium ion K + The percentage content is 0.8%, magnesium ion Mg ++ The percentage content of is 7.7%; The weight ratio of mixture and carnallite point brine is 3:1.

Embodiment 3

[0018] Example 3. A method for preparing low-sodium carnallite by mixing brine. The bischofite obtained by drying on the beach in salt fields and evaporating naturally and unsaturated old brine is mixed in a brine mixing container until the mixture of bischofite and unsaturated old brine Magnesium ion Mg ++ The percentage content of carnallite is 8.3%; then add carnallite point brine to the mixture to carry out the halogen crystallization reaction, and filter to obtain low-sodium carnallite; wherein, the composition of the added carnallite point brine is potassium ion K + The percentage content is 0.6%, magnesium ion Mg ++ The percentage content is 6.0%; the weight ratio of mixture and carnallite point brine is 2:1; the weight ratio of unsaturated old brine and bischofagsite is 3:1; the unsaturated old brine and carnallite point After the brine is added to the brine mixing container, it is fully mixed and continuously stirred for 0.5 hours; the finished brine mixing solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com