III-nitride semiconductor element and manufacturing method thereof

A nitride semiconductor and nitride technology, which is applied in semiconductor devices, semiconductor lasers, electrical components, etc., can solve the problems of GaN epitaxial layer cracks, inability to manufacture components, and complex growth and manufacturing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] Some embodiments of the present invention are described in detail as follows. However, the invention may also be practiced broadly in other embodiments than those described in detail, and the scope of the invention is not limited only by the following claims.

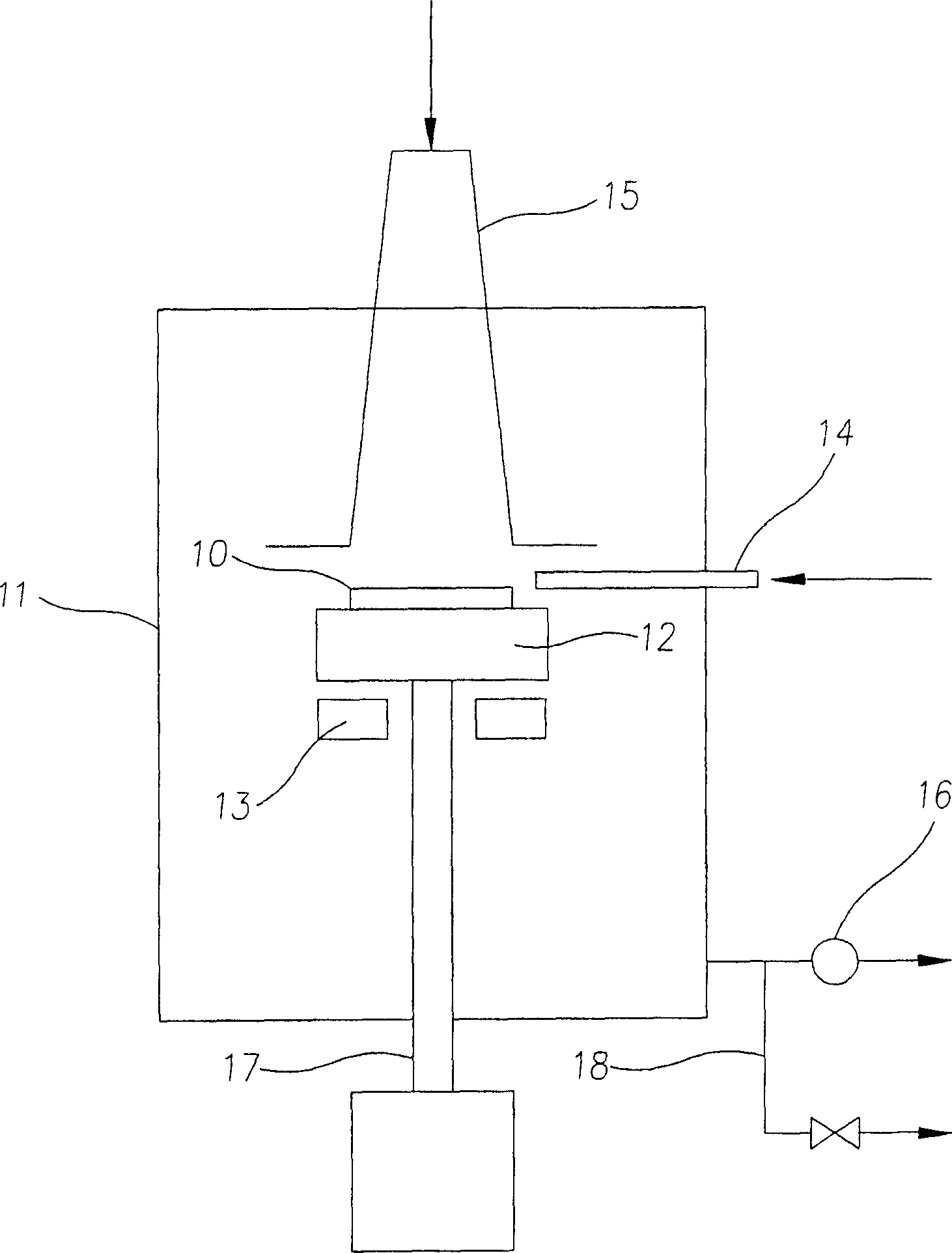

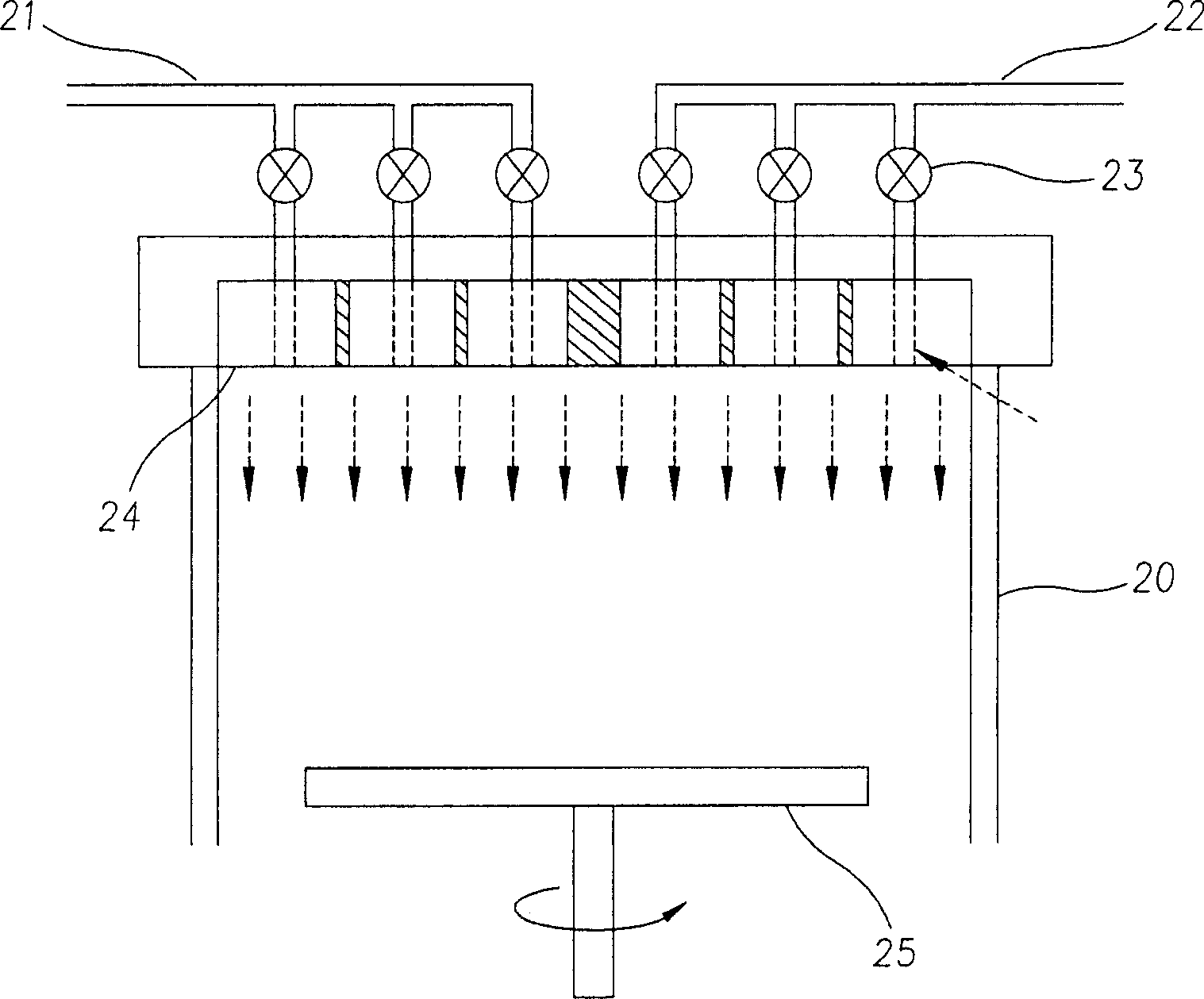

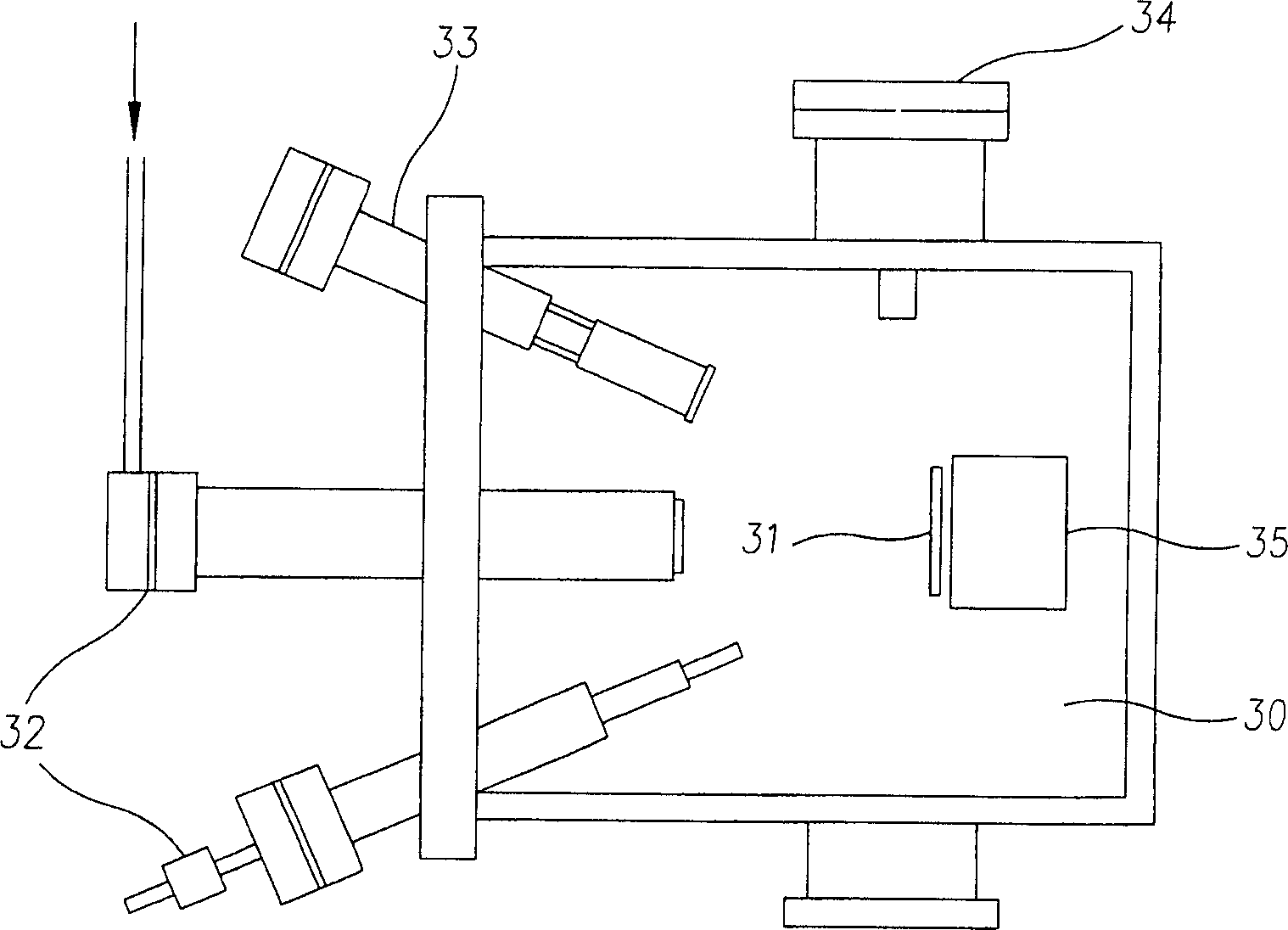

[0106] In order to overcome the problem between the existing GaN layer and the Si substrate. The present invention adds a stress relief layer composed of multiple material layers with different properties to the aforementioned two, such as Figure 7 Shown is a cross-sectional view of the structure of the semiconductor device according to the first embodiment of the present invention. On the silicon (Si) substrate 71, an amorphous silicon nitride layer 721, a metal aluminum interface layer 722, an amorphous aluminum nitride prelayer 723, and a polycrystalline group III nitride layer containing aluminum elements are sequentially formed. 724 to form the stress relief layer 72 , and then form the single crystal III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com