Method for extracting efficient component from mulberry leaf

A technology for active ingredients and mulberry leaf extracts, which is applied in the field of extracting active ingredients from mulberry leaves of plants, can solve problems such as easy oxidation in the purification process, and achieve the effects of high selectivity and low oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1 kg of mulberry leaf is extracted with 5 kg of water by a conventional method, and 200 g of D818 adsorption resin is added to the extract, stirred for 1 hour and then filtered. In the resin, the weight content of the mulberry leaf water-soluble extract is 1.5%, in the mulberry leaf water-soluble extract, the weight content of deoxynojirimycin alkaloids is 1.0%, and the weight content of mulberry leaf flavonoids is 3.0%;

[0022] Put the resin adsorbed with solute in the extraction kettle, and continuously feed CO 2 For elution, CO 2 The throughput is 5 kg / hour;

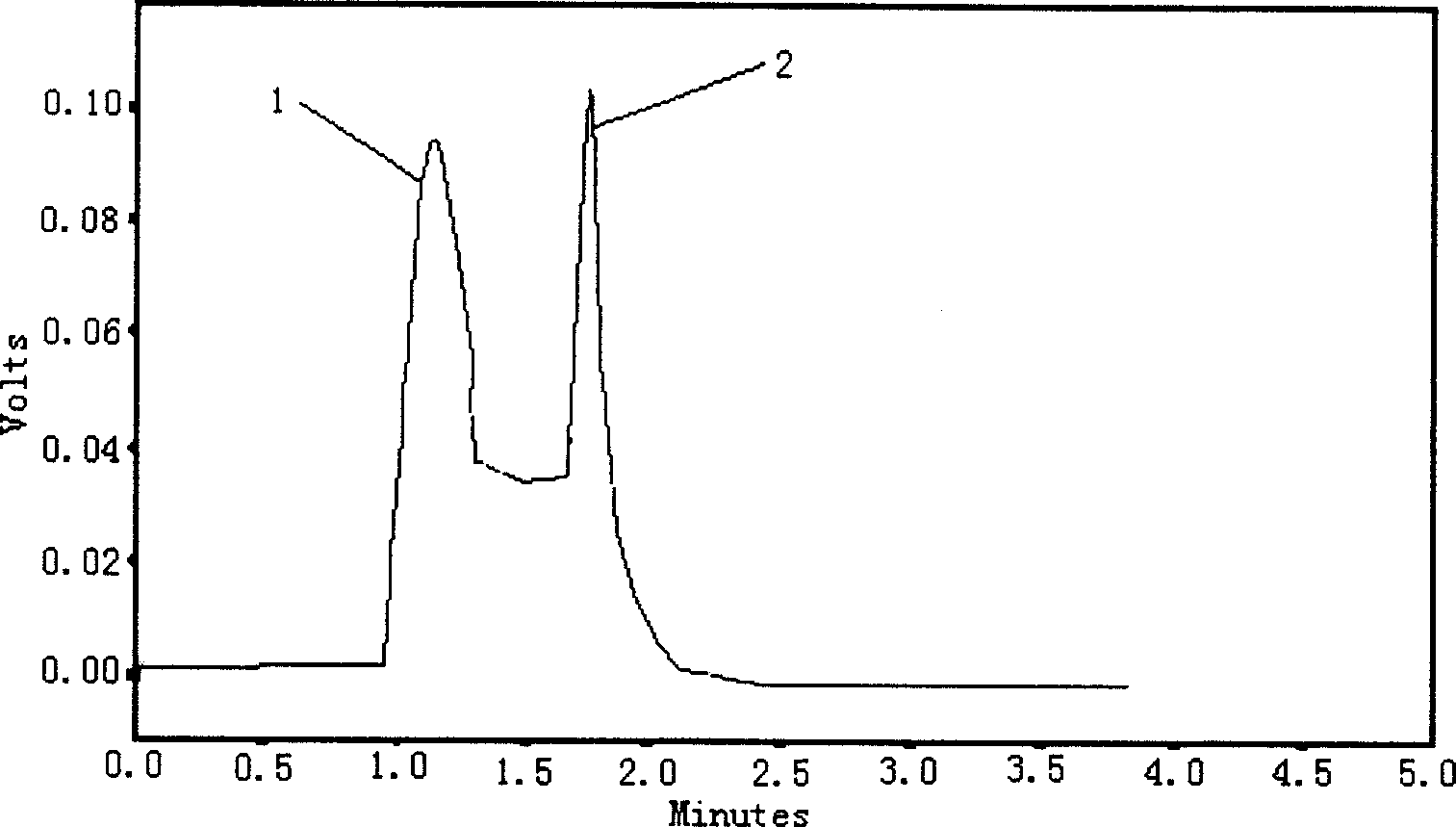

[0023] The extraction temperature is 35°C, the pressure is 10MPa, and the CO that flows out of the extraction tank after 1.5 hours of extraction is collected 2 , depressurized to atmospheric pressure, CO 2 Empty, obtain the residue after pressure relief, analyze by high performance liquid chromatography, deoxynojirimycin alkaloid content is 5.7%, mulberry leaf flavonoid is 47%. The liquid chromatogram is a...

Embodiment 2

[0025] After 1 kilogram of mulberry leaf was extracted with 5 kilograms of water, the extract flowed through the adsorption column (80 mm in diameter) filled with 200 grams of HZ802 adsorption resin respectively. In the resin, the weight content of mulberry leaf water-soluble extract was 0.2%. In the leaf water-soluble extract, the weight content of deoxynojirimycin alkaloids is 0.6%, and the weight content of mulberry leaf flavonoids is 2.2%;

[0026] Put the resin adsorbed with solute in the extraction kettle, and continuously feed CO 2 , calculated per kilogram of resin adsorbed with water-soluble extract of mulberry leaves, CO 2 The throughput is 10 kg / hour;

[0027] The extraction temperature is 60°C, the pressure is 15MPa, and the CO outflowing from the extraction tank after 6 hours of extraction is collected. 2 , depressurized to atmospheric pressure, CO 2 Empty to obtain the residue after pressure relief, and analyze by high performance liquid chromatography, the co...

Embodiment 3

[0029] 2 kg of traditional Chinese medicine mulberry leaves are extracted with 7 kg of water, 100 g of adsorption resin HZ818 and 100 g of ion exchange resin D315 are added to the extract for adsorption, stirred for 1 hour and then filtered. In the resin, the weight content of the mulberry leaf water-soluble extract is 1%, in the mulberry leaf water-soluble extract, the weight content of the deoxynojirimycin alkaloid is 1.1%, and the weight content of the mulberry leaf flavone is 3.0%;

[0030] Put the resin adsorbed with solute in the extraction kettle, and continuously feed CO 2 For elution, CO 2 The feed rate is 25 kg / h, the extraction temperature is 65°C, and the pressure is 10MPa. CO collected from the extraction tank after 4 hours of extraction 2 , depressurized to atmospheric pressure, CO 2 Empty to obtain the residue after depressurization, analyzed by high performance liquid chromatography, the content of deoxynojirimycin alkaloid is 7.2%, and the content of mulberr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com