Composition board type high-frequency large-scale ozone generator

An ozone generator and combined plate technology, applied in the field of high-efficiency ozone production devices, can solve the problems of affecting efficiency and ozone concentration, large energy loss of dielectrics, large equipment volume and weight, etc., and achieve light weight, anti-transport vibration, Produce fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

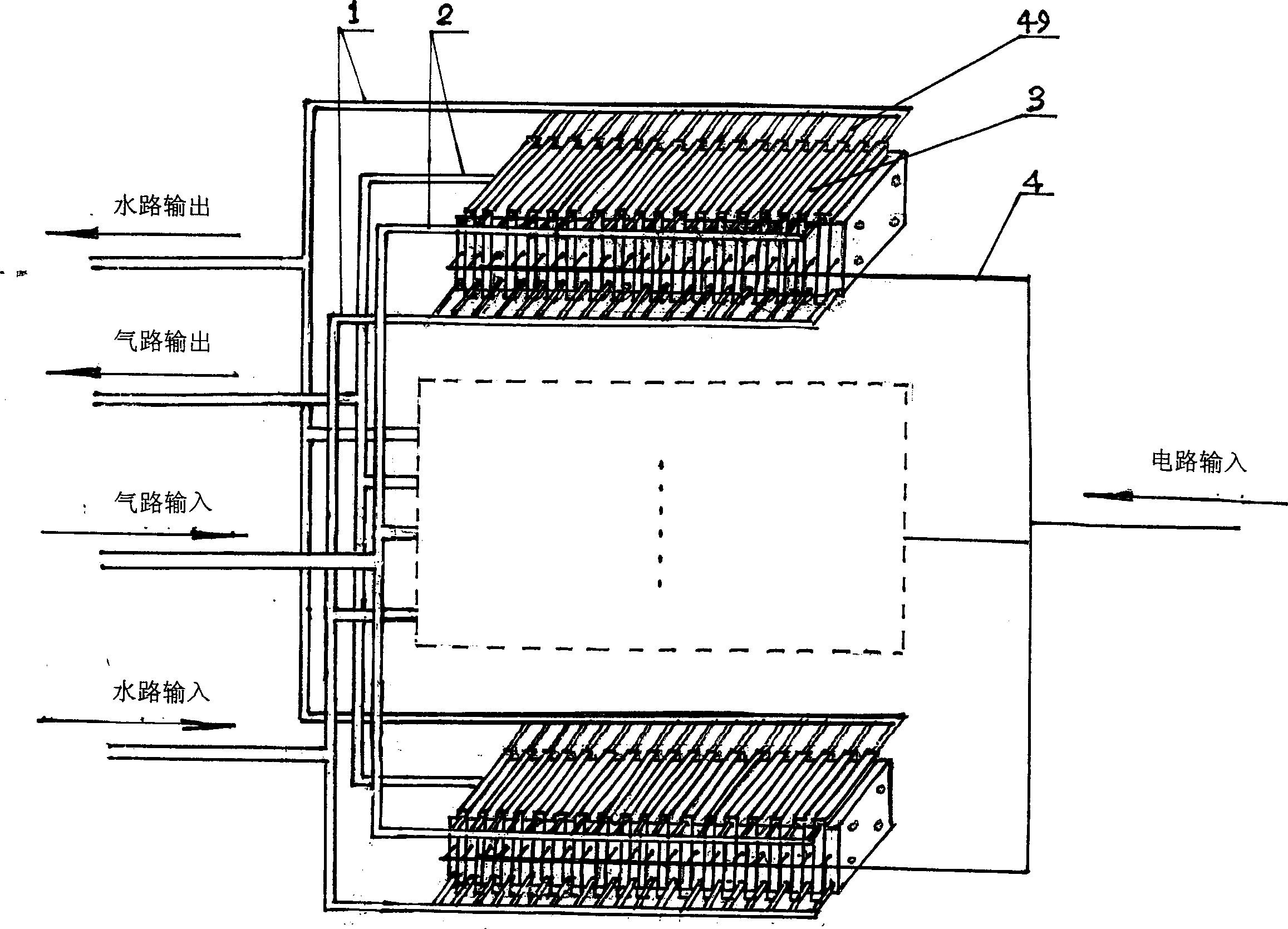

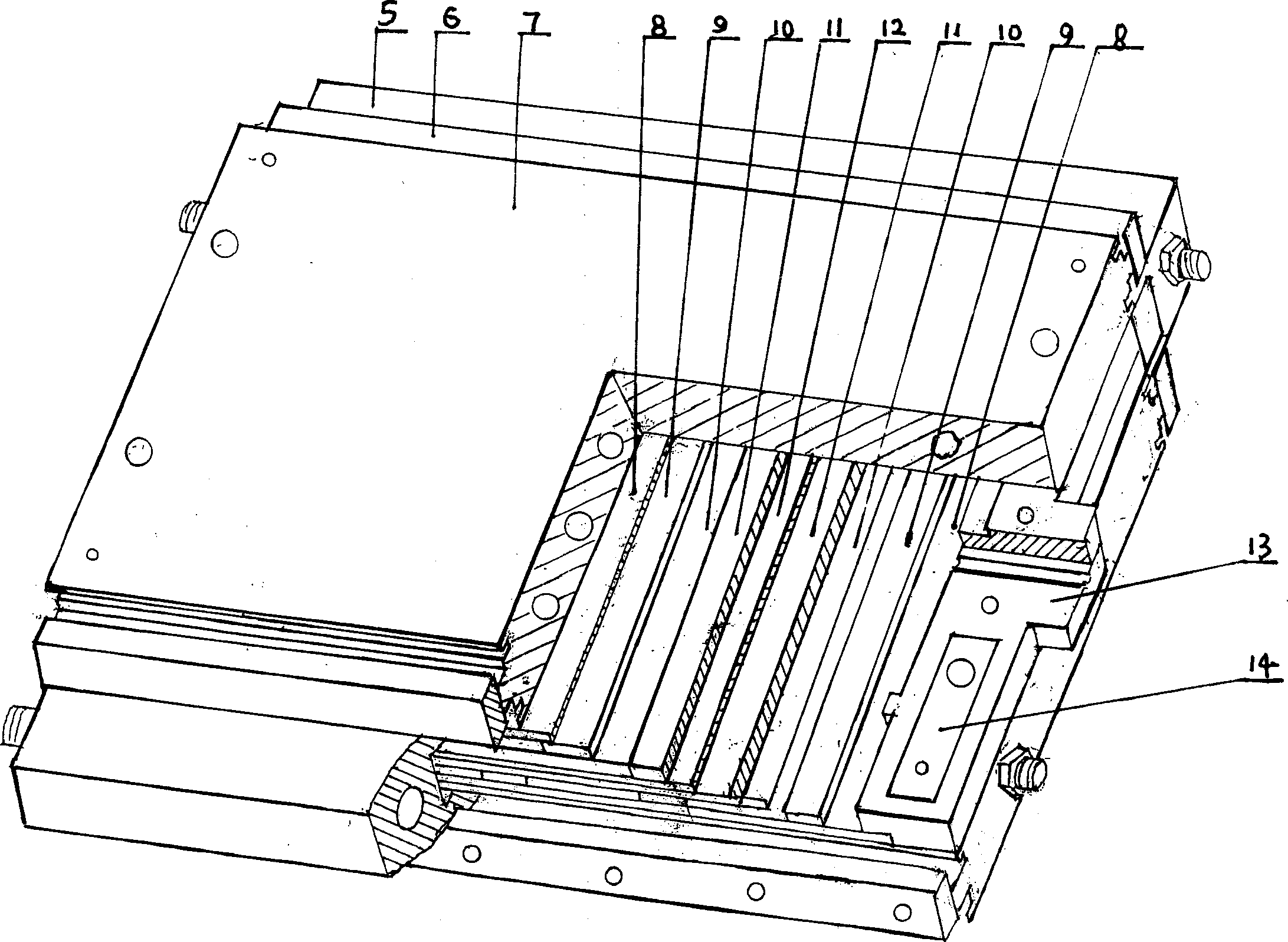

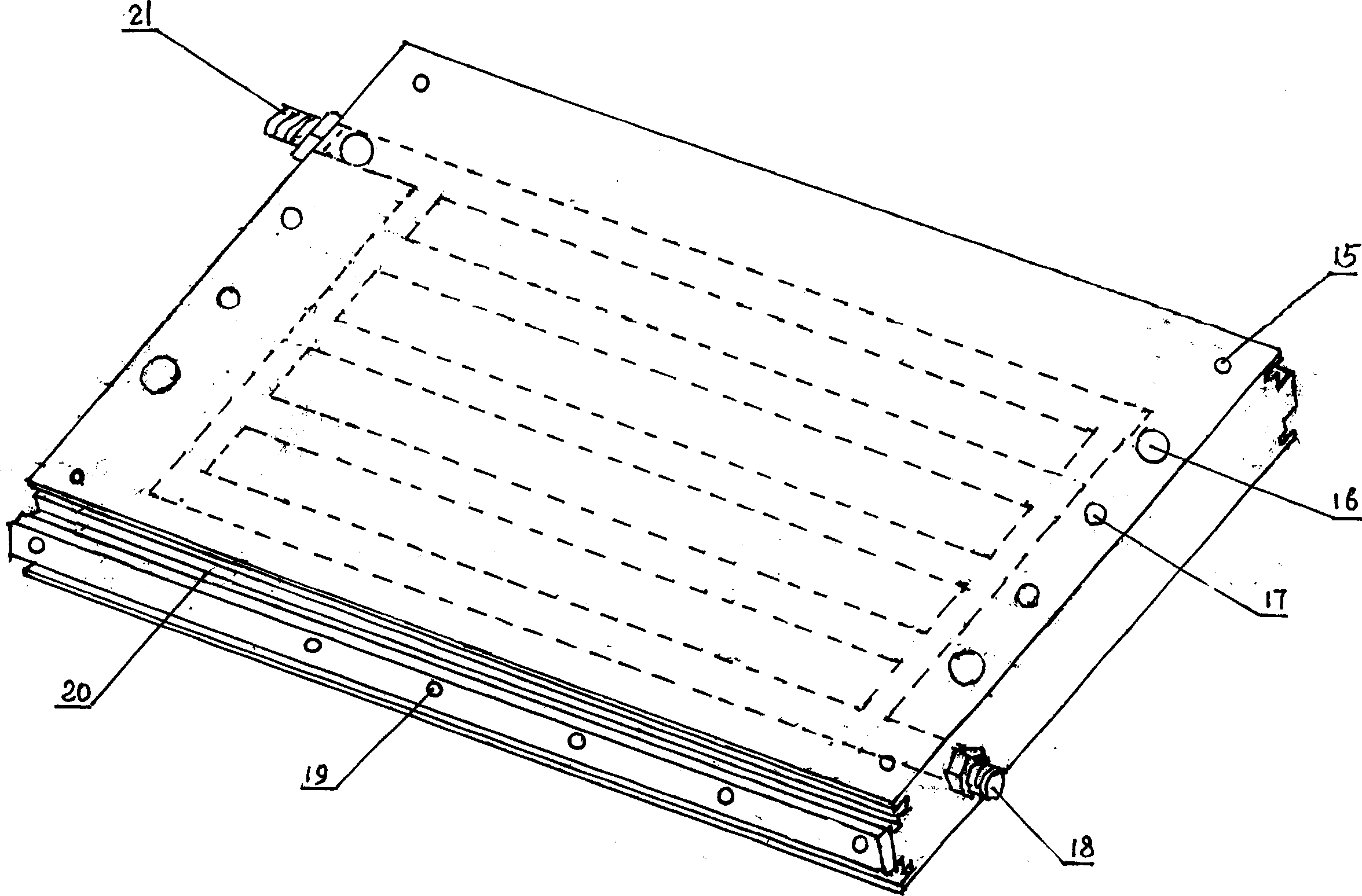

[0035] The structure and working principle of the present invention will be described in detail below through the embodiments in conjunction with the accompanying drawings. The present invention is realized according to the following technical solutions: its structure (see diagram 2-1 3) It mainly consists of ground electrode (7), ceramic sheet dielectric body (8), heat conduction gasket (9), high voltage electrode (10, 11), elastic rubber pad (12), end seal (13), spacing It consists of a positioning piece (14), an air guide pipe (5), a bead (6) and water and air pipelines (1, 2). Ground electrode(7)( image 3 Shown) is made of high thermal conductivity aluminum alloy material, measuring 260mm×170mm×25mm, with high mechanical strength and large heat dissipation area. The ground electrode is also a water-cooled high-efficiency radiator and a base for fixing other components. The ground electrode (7) is provided with a plurality of φ11mm circular hole-shaped water-cooling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com