Green house barn

The technology of a greenhouse and a roasting room is applied in the fields of roasting and preparing equipment for agricultural products, and can solve the problems of high labor intensity, low utilization rate of heat energy, insufficient labor force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

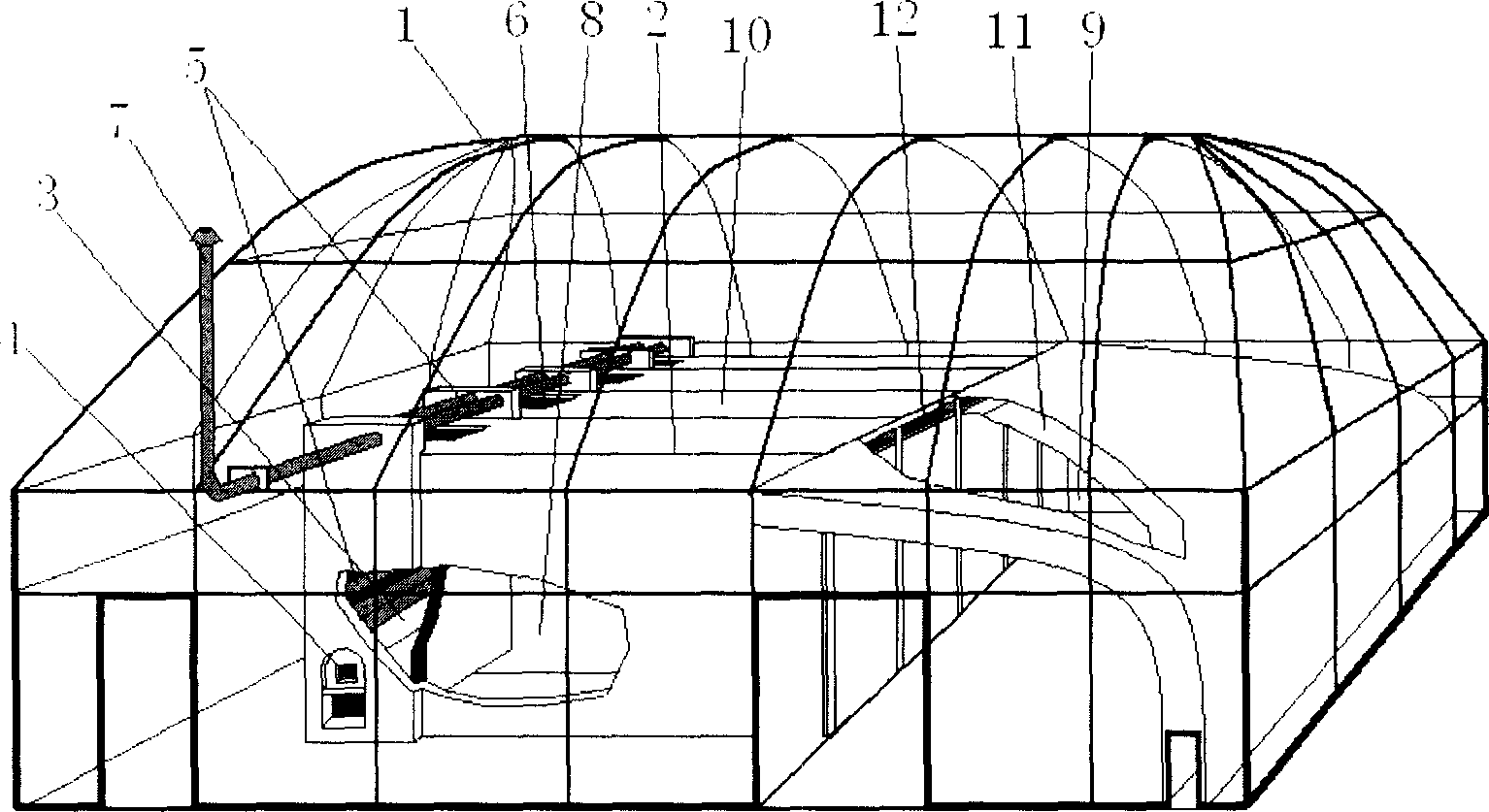

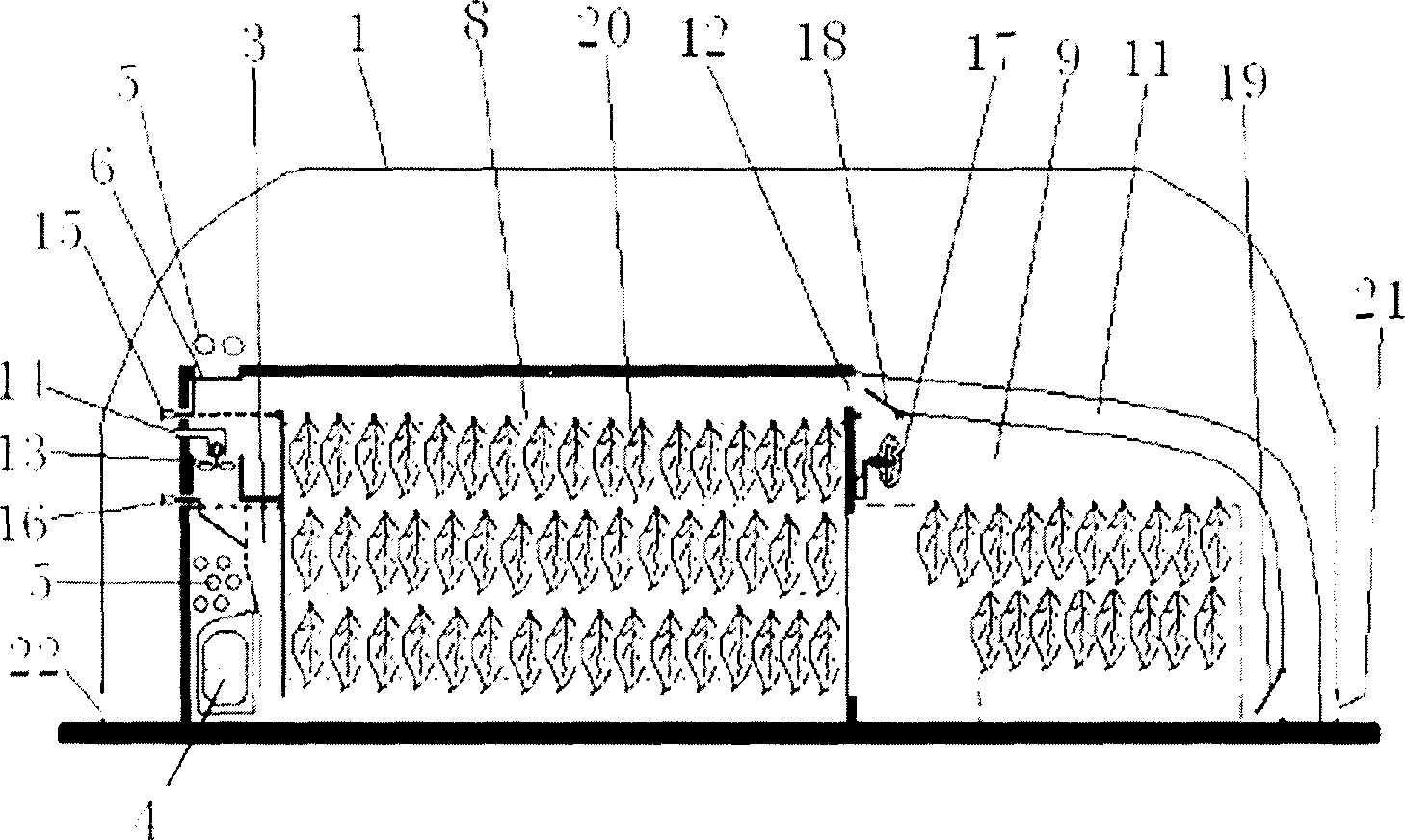

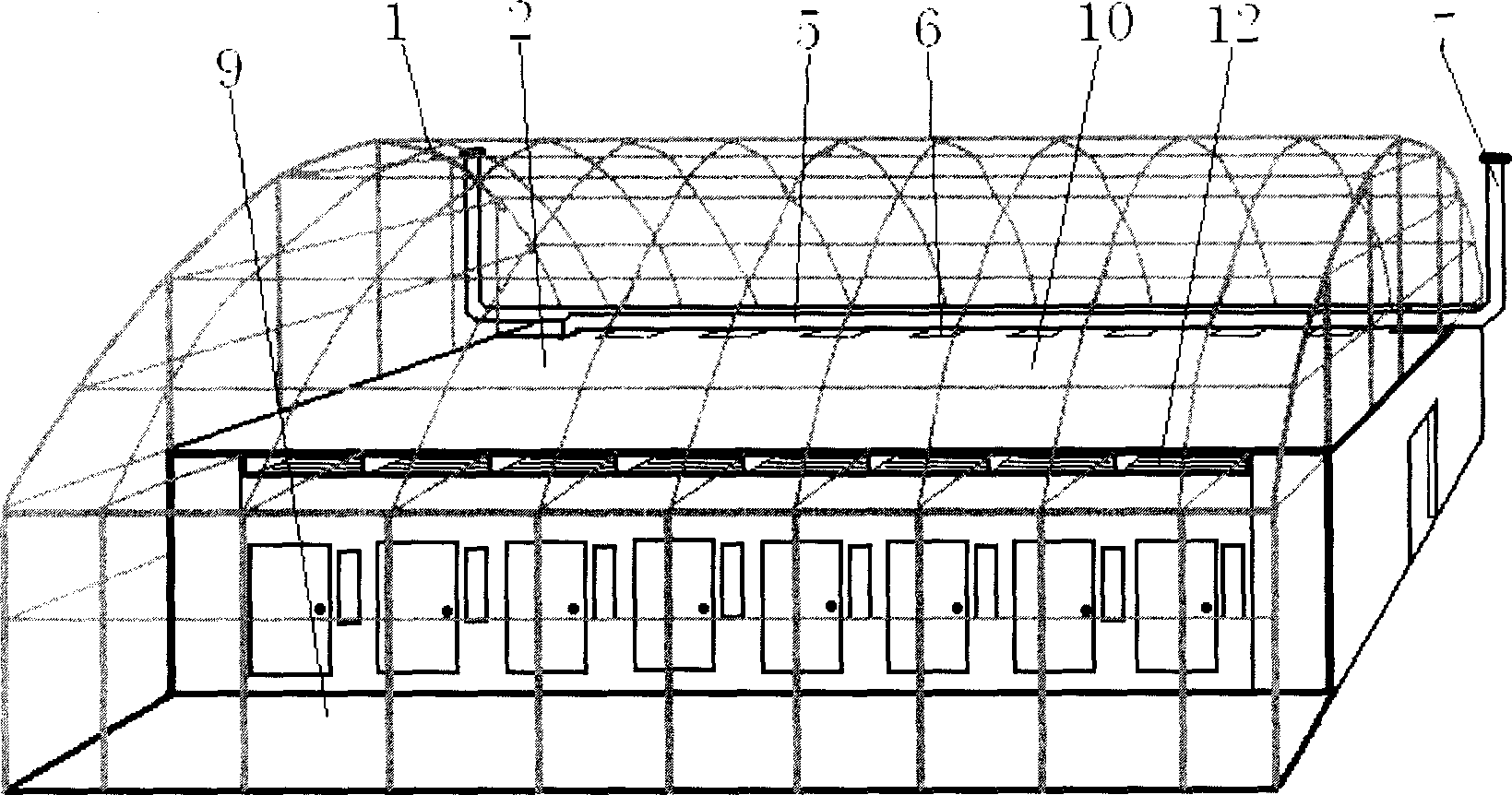

[0030] as attached Figure 1-6 All the embodiments shown adopt the sunlight greenhouse 1 to cover the baking device 2 . The sunlight greenhouse 1 can be made of plastic film, sunlight board, glass and the like. Utilize the sunshine greenhouse 1 to store the heat and sunlight emitted from the outer surfaces of the baking device 2 including the heating chamber 3, the baking chamber 8, the stove 4, the heat exchange pipe 5 connected to the chimney, and the plate-like moisture removal channel 11. radiant heat.

[0031] as attached figure 1 and 2In the shown embodiment 1, the baking device 2 is provided with a yellowing chamber 9, and the hot and humid gas produced by the heat supply chamber 3 and the baking chamber 8 is completely or partially discharged into the yellowing chamber 9 through the dehumidification air outlet 12, and is utilized from the yellowing chamber 9. The hot and humid gas discharged from the baking chamber 8 provides temperature and humidity for the tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com